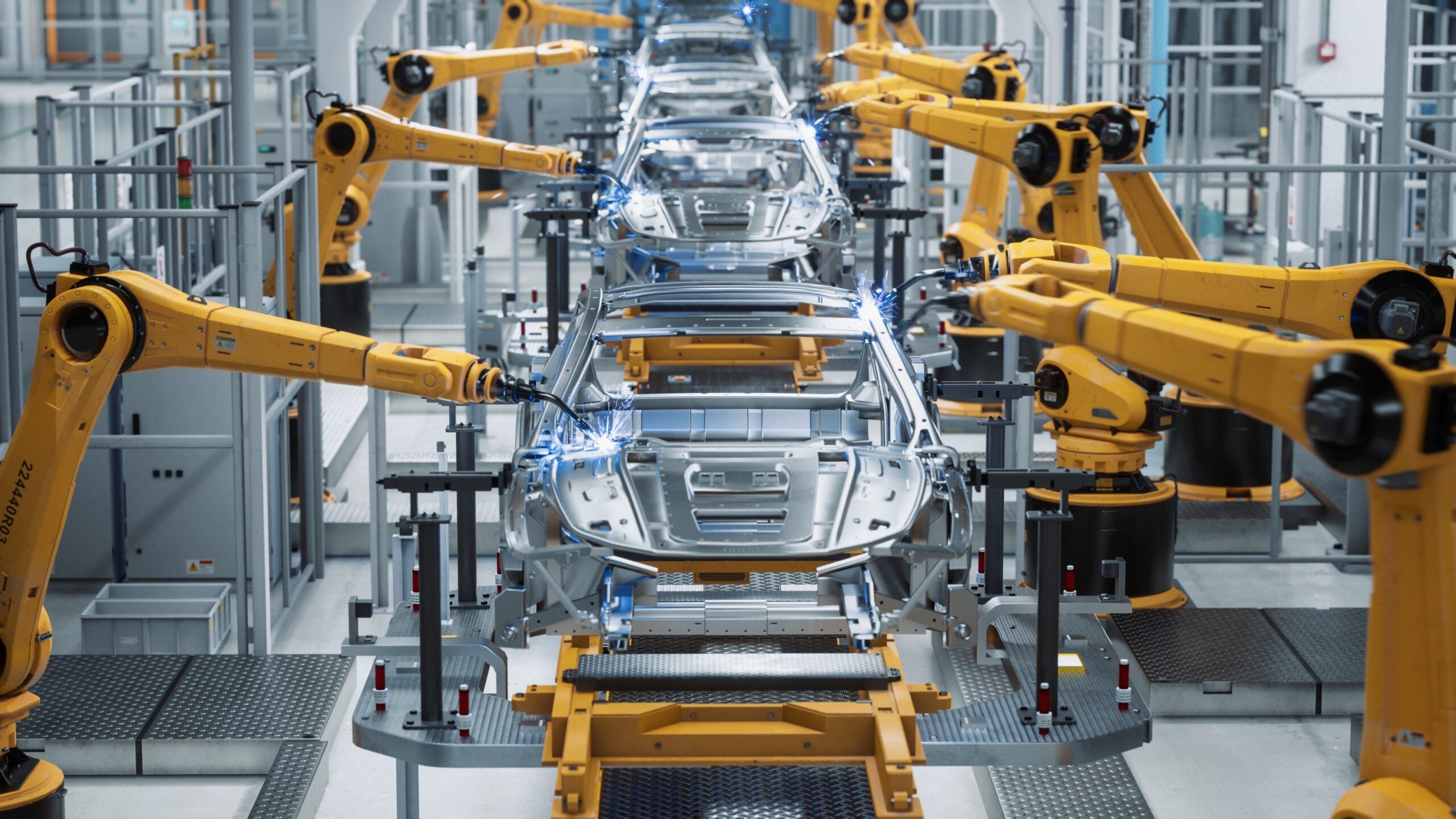

We asked this week: Is global automotive capacity headed for a day of reckoning? In the ever-evolving landscape of the automotive industry, the lower utilisation conundrum appears to be here to stay. The recovery in global Light Vehicle (LV) demand in 2023 has been stronger than expected, as supply constraints eased in most markets. The outlook for 2023 has been increased by 4%, from 85.8 million units in January to 89.2 million units in November. However, this recovery and, more specifically, consumers still face headwinds from high vehicle prices (with the exception of China’s price war). High prices have kept the recovery in check and some consumers on the sidelines, as pressure on vehicle production eases. With the current high-price environment as a backdrop, the progression of the Electric Vehicle (EV) transition and the potential for other external shocks, we can’t help but raise the caution flag about the prospects for the medium-term forecast and a recovery in demand to pre-pandemic levels. We had recently already trimmed the global LV forecast by an average of 7.5 million units a year throughout the forecast horizon, citing pricing pressure as the main driver. However, additional cuts to the outlook post-recovery could be on the horizon if pricing isn’t addressed. Sustained higher prices effectively shrink the new vehicle market, causing it to behave more like a premium market, thus squeezing out some buyers that simply don’t have an option but to keep their vehicle, buy a used vehicle or not own one. Given the likelihood of manufactures embracing margin and not chasing volume, there is a plausible scenario that lowers demand further, adding more uncertainty to the billions invested in shifting and building vehicle capacity to support the push to electrification.

COP28

We explained this week: Why COP28 is “the most important COP” since the Paris Agreement. In this article, GlobalData’s Energy Monitor takes you through what to expect at COP28, the UN climate conference taking place in December in Dubai, United Arab Emirates (UAE). n 30 November, some 75,000 delegates including politicians, ministers, representatives from civil society, the private sector, international organisations and media organisations (including Energy Monitor) will descend on Expo City Dubai for what is expected to be the largest COP ever. Leaders including Pope Francis and King Charles III are set to attend (although reportedly, US President Joe Biden will not). So. Why is COP28 the most important COP since Paris in 2015? In many ways, the 28th annual UN climate conference in Dubai, (literally ‘Conference of the Parties’), is expected to be similar to what we have seen before. Talks will largely focus on how to honour the 2015 Paris Agreement, a legally binding agreement to limit global warming to at least below 2°C above pre-industrial levels, and ideally 1.5°C, which has been signed by 195 parties. For the past few years, ever since the Intergovernmental Panel on Climate Change (IPCC) published a report in 2018 warning that the difference between 1.5°C and 2°C is significant, parties have focused on the more ambitious target of 1.5°C, which would require global emissions to reach ‘net zero’ by 2050. To be on track for net zero 2050, the IPCC has said that emissions will have to drop 45% compared with 2010 levels by 2030. However, current trends have analysts predicting record emissions in 2023, a year in which a series of emissions and extreme weather records have been broken. The World Meteorological Organisation (WMO) also warned this year that the world is likely to experience at least one year where the global average surface temperature exceeds 1.5°C above pre-industrial levels over the next five years. Meanwhile, the recent UN Production Gap report warned that governments are currently planning to produce 110% more fossil fuels in 2030 than would be consistent with limiting warming to 1.5°C.

More UK EVs

Big news for UK Auto plc today as Nissan confirmed multiple earlier media reports it would make two new fully electric models – in addition to the Leaf – at its Sunderland plant in northeast England. The announcement also included plans for three battery gigafactories and up to GBP3bn investment. Nissan said it was ‘great news for Nissan’s 7,000 UK employees and the 30,000 jobs supported in the UK supply chain’. The EV project includes future all-electric versions of the Qashqai and Juke crossovers as well as the next generation Leaf, the EV that started it all for the Japanese automaker.

Inductive charging development

Talk of the Leaf reminded us of a Nissan Europe presentation years ago, ahead of that pioneering EV’s debut, with talk of a coming utopia where EVs would be charged by hidden subsurface pads as they drove on the road above. That one is still being worked on – there have been successful trials – but a Mahle development for static charging may prove more useful to EV drivers in the nearer term. This week the company said it had developed a positioning system which allows an electric vehicle to be precisely aligned above an inductive charging coil in the floor. SAE International has now chosen that positioning system as the global standard for wireless charging, closing “the last gap in standardisation of inductive charging that has been unfilled for 10 years. The cross manufacturer product now paves the way for the comprehensive and rapid market launch of this attractive alternative to wired charging for batteries and electric and hybrid vehicles.

BYD’s 6m NEVs

Perhaps from the ‘be afraid’ department: BYD has just built its six millionth new energy vehicle (NEV), at its Zhengzhou factory. You’ll know, of course, the Chinese term NEV encompasses hybrid, plug-in hybrid and BEV models. Even more frightening perhaps: BYD told us it had built its five millionth NEV only three months ago. Do the math. The nominated milestone NEV #6m was a BAO 5 hybrid SUV from the Fangchengbao sub brand. BYD also said it had set an October monthly sales record, selling 300,000 NEVs.

JLR reskilling pays

Tata Motors owned Jaguar Land Rover claims a training programme developed to provide a new career route for the next generation of digital engineers has helped “deliver more than GBP430m in value for the business over the past year”. The data engineering conversion programme, launched in 2021, has provided dozens of new data engineers with new skills. Digitally skilled workers are now able to use data to predict global supply and manufacturing challenges to make decisions to protect build schedules for a strong order bank of 150,000 vehicles, contributing to a record cash flow performance for the business for the first half of the 2023/24 financial year. The multi million pound value return was achieved by developing digital tools to deliver process efficiency, automate parts ordering to protect supply and monitor global industry trends to understand the risk of future challenges and trigger mitigation activities.

Canada union deal

Unifor union members at Magna Integram in Canada ratified a new tentative agreement after a five day strike at the auto parts manufacturing plant. “The strike action at the seating plant led to a fair contract. Unifor members at Integram have paved the way for higher standards not only for our themselves but for auto parts workers across the industry,” said Unifor national president Lana Payne in a statement published on the union website. “Together, we’ve shown that when workers unite, we can achieve great progress and set new standards for wages, benefits and work ownership throughout the independent auto parts supplier sector.” The tentative agreement covers 800 members at a plant in Windsor, Ontario, a tier-one supplier of seating products for the Chrysler Pacifica assembled at the Stellantis Windsor Assembly Plant and foam seating parts for the Ford Bronco and Ranger built in United States factories.

Volta revival?

Luxor Capital Group, a former shareholder and creditor to Swedish start-up Volta Trucks, is in ‘advanced talks’ with the firm’s administrators, Sky News reported. The talks concern a deal that could save hundreds of UK jobs, where 600 people were employed by the firm. Last February, the firm raised EUR230m in a financing round which included Luxor Capital, a US-based credit hedge fund. Electric commercial vehicle start-up Volta initiated bankruptcy proceedings over a month ago, assigning joint administrators joint administrators from Alvarez & Marsal Europe for its UK subsidiary. In a statement from the board of directors when the firm announced its bankruptcy proceedings, Volta said that the collapse of battery supplier Proterra had a “significant impact” on its manufacturing plans. The start-up had previously raised approximately EUR300 million ($316 million) from investors and said it had an order book of more than 5,000 vehicles.

Sodium-ion break through

Swedish battery maker Northvolt claims it has made a breakthrough with a sodium-ion battery co-developed with research partner Altris for ‘the global expansion of cost-efficient and sustainable energy storage systems worldwide’. Peter Carlsson, CEO of Northvolt, said: “It’s an important milestone for Northvolt’s market proposition, but battery technology like this is also crucial to reach global sustainability goals, by making electrification more cost-efficient, sustainable and accessible worldwide.” Northvolt says the cell has been validated for an energy density of over 160 watt-hours per kilogram at the company’s R&D and industrialisation campus, Northvolt Labs, in Vasteras.

VW, too, hikes US pay

Volkswagen of America has announced an 11% pay raise for Chattanooga assembly plant production workers. The increase is effective starting in December and a compressed wage progression timeline begins in February. US operators of non-union plants, mostly in southern states, have been announcing wage hikes since the United Auto Workers (UAW) union reached agreement with the Detroit Three automakers on a new pay deal good until the end of April 2028 which includes a 25% increase in base wages and will cumulatively raise the top wage by 33%, compounded with estimated cost of living adjustments to over US$42 an hour. The deal included a $5,000 bonus and an 11% immediate pay hike upon ratification. The contract also hiked wages of current temporary workers by 150% by 2028 and would make them permanent employees. The UAW has promised to step up its long-running campaign to ‘organise’ the non-union plants such as VW’s.

Hyundai India batteries

Hyundai Motor plans to invest INR7bn (US$84m) in India to assemble battery packs for battery electric vehicles (BEVs) to be produced in the country, according to media reports this week. Local subsidiary, Hyundai Motor India (HMIL) plans to complete construction of the first phase of the plant in Chennai by 2025 with initial capacity for 75,000 battery packs per year. Hyundai expects local production will help reduce the cost of its BEVs in the country and help lift local demand. The company has targeted increasing its share of the BEV market from 2% now to 22% by 2030 as part of its global growth ambitions.

Hyundai transmissions for VWs

Volkswagen pretty much pioneered mass production, twin clutch, direct shift gearbox (DSG) automatic transmission technology with 2005’s redesigned Golf/Jetta model line – not without teething issues – so it’s a big turnaround to see this: Hyundai Transys, the automotive components manufacturer affiliated to Hyundai Motor Group, has begun supplying transmission systems to VW Group as part of a US$542m deal recently signed with the German automaker, according to local reports. Hyundai Transys was established in 2019 following the merger of Hyundai Dymos and Hyundai Powertech, two major Hyundai component manufacturing affiliates. The merged company is now a major supplier of powertrain, transmission and automotive seating to Hyundai Motor Group with annual revenue of KRW10trn (US$7.7bn). The company wants to further strengthen its business with customers outside Hyundai group companies which last year accounted for 90% of revenue. It has also invested heavily in the battery electric vehicle (BEV) powertrain segment. Volkswagen is the latest foreign automaker to sign a contract with the company following a KRW700bn (US$540m) transmission deal with Stellantis at the end of last year.

Blue Oval Marshall ‘go’ but…..

Ford said this week it had been (re)evaluating BlueOval Battery Park Michigan in Marshall. “We are pleased to confirm we are moving ahead with the Marshall project, consistent with the Ford+ plan for growth and value creation. However, we are right-sizing as we balance investment, growth, and profitability,” the automaker said in a statement. “The facility will now create more than 1,700 good-paying American jobs to produce a planned capacity of approximately 20 GWh.” Ford had originally suggested the site would create around 2,500 jobs but had paused the project in September.

BMW axes ICE

BMW has stopped combustion engine production in Germany to make way for a new EV plant in Munich. MotorAuthority.com said the automaker was spending EUR400m on the new vehicle plant and, to make way for the facility expected to build some of the upcoming Neue Klasse EVs, an existing plant where the automaker built 4-, 6-, 8-, and 12-cylinder engines over the past 60 years will be removed. The plant is the sole location for BMW engine production in Germany and built its last engine, a V8, earlier this month. Motor Authority said BMW was continuing to build engines at plants in Austria and the United Kingdom (Hams Hall).

Battery swapping deal

EV battery swapping has long been gaining some ground in China and got a boost this week: BEV startup Nio said it had agreed a deal with state owned automaker Changan Automobile to promote the technology. Nio said it would work with Chongqing based Changan to “jointly facilitate the formulation of standards for swappable batteries, build and share the battery swapping network, develop swappable vehicles and establish an efficient battery asset management mechanism”. Shanghai based Nio, listed on the New York Stock Exchange (NYSE), said in a statement: “Expanding recharging networks is core to the development of the smart electric vehicle industry. It is proven that battery swapping is a quick, efficient and sustainable recharging [service] for smart electric vehicles.”

Hyundai building EVs in…..Singapore?

It is. Hyundai Motor Group officially opened its Singapore global innovation centre with an event attended by chairman Euisun Chung, Singapore’s deputy prime minister Lawrence Wong and South Korean trade minister Ahn Duk-geun. The automaker said Hyundai Motor Group Innovation Center Singapore (HMGICS) would focus on research and development (R&D) of new human centred mobility technology. The company began construction of the centre, in the Jurong district, in 2020 but completion was delayed due to the Covid pandemic. The aim of the centre was to develop and test advanced vehicle and manufacturing technology which will be adopted later across the group’s global operations. The seven storey building, with total floor space of 90,000 sq m, includes a high tech assembly facility with capacity for 30,000 electric vehicles annually, R&D facilities, customer experience research centres, offices and a rooftop test track.

Have a nice weekend.

Graeme Roberts, Deputy Editor, Just Auto