After being reported earlier on just-auto, Nissan has confirmed that it will make two new fully electric models – in addition to the Leaf – at its Sunderland plant in northeast England.

The announcement also included plans for three battery gigafactories and up to £3bn investment. Nissan said it was ‘great news for Nissan’s 7,000 UK employees and the 30,000 jobs supported in the UK supply chain’.

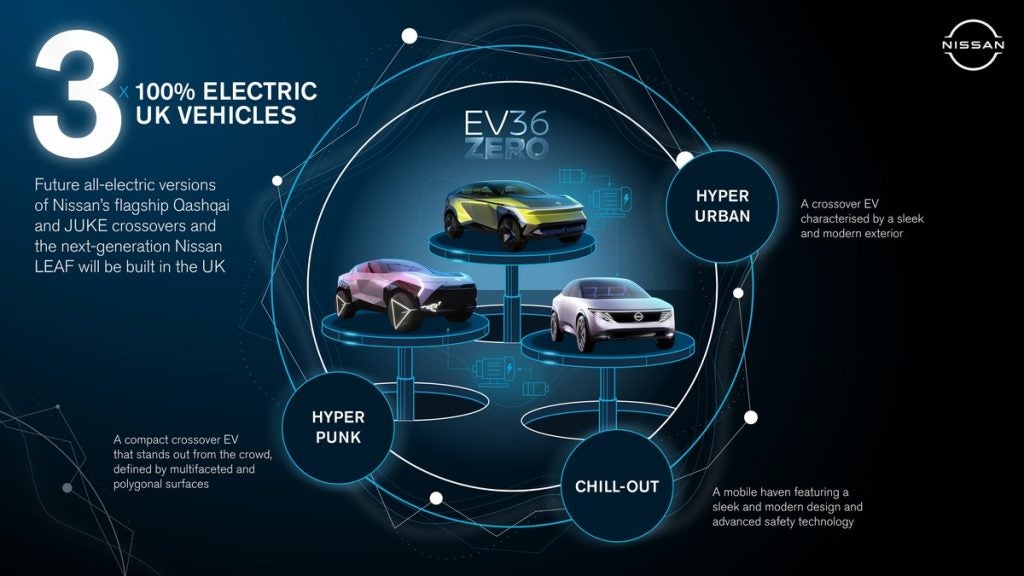

The EV project includes future all-electric versions of Nissan’s Qashqai and Juke crossovers as well as next-generation Nissan Leaf.

Nissan said that both vehicle and battery manufacturing will be powered by the ‘EV36Zero Microgrid’, which will incorporate the wind and solar farms at Nissan and will have the capability to deliver 100% renewable electricity to Nissan and its neighbouring suppliers.

Announcing the plans at the Sunderland plant, Nissan President and CEO Makoto Uchida said: “Exciting, electric vehicles are at the heart of our plans to achieve carbon neutrality. With electric versions of our core European models on the way, we are accelerating towards a new era for Nissan, for industry and for our customers.

“The EV36Zero project puts our Sunderland plant, Britain’s biggest ever car factory, at the heart of our future vision. It means our UK team will be designing, engineering and manufacturing the vehicles of the future, driving us towards an all-electric future for Nissan in Europe.”

How well do you really know your competitors?

Access the most comprehensive Company Profiles on the market, powered by GlobalData. Save hours of research. Gain competitive edge.

Thank you!

Your download email will arrive shortly

Not ready to buy yet? Download a free sample

We are confident about the unique quality of our Company Profiles. However, we want you to make the most beneficial decision for your business, so we offer a free sample that you can download by submitting the below form

By GlobalData

The announcement follows Nissan’s confirmation that all its new cars in Europe from now will be fully electric, and that it expects its passenger car line-up in Europe to be 100% electric by 2030. It also builds on Nissan’s Ambition 2030 vision to become a truly sustainable company, driving towards a cleaner, safer, and more inclusive world.

UK Prime Minister Rishi Sunak welcomed the news. He said in a statement: “Nissan’s investment is a massive vote of confidence in the UK’s automotive industry, which already contributes a massive £71 billion a year to our economy. This venture will no doubt secure Sunderland’s future as the UK’s Silicon Valley for electric vehicle innovation and manufacturing.

“Making the UK the best place to do business is at the heart of our economic plan. We will continue to back businesses like Nissan to expand and grow their roots in the UK every step of the way as we make the right long term decisions for a brighter future.”

Manufacturing investment

Nissan’s latest investment includes up to £1.12bn into its UK operations and wider supply chain for R&D and manufacturing of the two new models announced, today, including facility and manufacturing process improvements, skills training, and tooling for suppliers. This follows the £423m investment announced by Nissan in the first phase of EV36Zero for the first future EV.

Nissan said the three new electric vehicles represent the future for all three models currently manufactured in Nissan Sunderland Plant: Nissan Qashqai (the UK’s best-selling car of 2022); Nissan Juke; Nissan Leaf (described by Nissan as the world’s first mass market EV, of which more than a quarter of a million have been built in Sunderland).

The three future models will be inspired by three all-electric concept models, two of which were recently unveiled at the Japan Mobility Show:

- The Nissan Hyper Urban Concept, a crossover EV

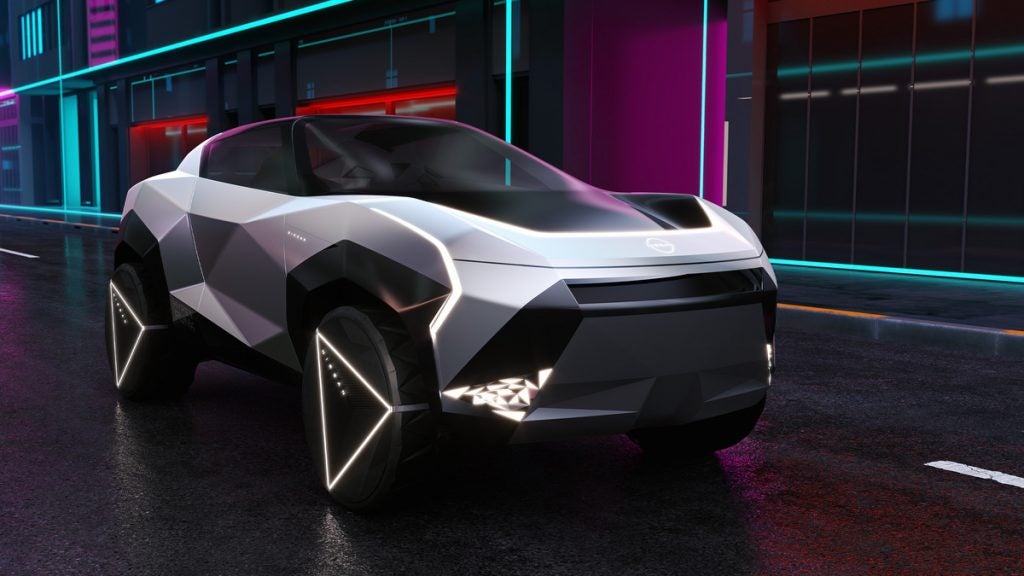

- The Nissan Hyper Punk Concept, an all-electric compact crossover with an ‘exterior aesthetic defined by multifaceted and polygonal surfaces’.

- The Nissan Chill-Out Concept, unveiled in 2021 and previously confirmed as the inspiration for a future EV to be built in Sunderland.

Further information about the three models, including names, specifications and launch dates, will be released at a later time, Nissan said.

Complementing vehicle and battery production is the Sunderland City Council-initiated Microgrid project, which will have the capability to deliver 100% renewable electricity to Nissan and its neighbouring suppliers, incorporating the existing Nissan wind and solar farms, including Nissan’s brand new 20MW solar farm.

The additional two models, alongside an additional gigafactory and further investment for infrastructure projects, will result in an investment of up to £2bn. It means Nissan’s plans for the future electric versions of Qashqai, Juke and the replacement for Leaf, will enable up to a £3bn investment in the UK, Nissan said.

In addition, the UK Government has awarded £15m of funding for a £30m collaborative project led by Nissan. It will strengthen the technical expertise and R&D zero emission vehicle capability of the Nissan Technical Centre (NTCE) in Cranfield, Bedfordshire, increasing opportunities for securing additional UK R&D investment in future vehicle models.

EV36Zero is a key part of Nissan Ambition 2030, the company’s long-term vision to become a truly sustainable company, driving towards a cleaner, safer, and more inclusive world. In this period Nissan will deliver exciting, electrified vehicles and technological innovations while expanding and transforming its operations globally. The vision supports Nissan’s goal to be carbon neutral across the lifecycle of its products by fiscal year 2050.

UK an increasingly competitive location for EV production – SMMT

The UK automotive trade body, SMMT welcomed the Nissan news. Mike Hawes, SMMT Chief Executive, said: “The UK’s automotive manufacturing sector continues to demonstrate its investment attractiveness with yet another significant commitment.

“This new announcement from Nissan – coming on the back of billions recently committed by other manufacturers and supported by the UK government – underlines Britain’s position as an increasingly competitive location for electric vehicle production.

“It is tremendous news for the company, its workforce, the region and the UK’s supply chain, which will drive economic growth and decarbonisation across the UK.”

UK still needs more battery plants – analyst

One analyst pointed out that while Nissan’s announcements are welcome, the UK still needs to secure more investment in battery manufacturing. Sheena Patel, director and automotive sector specialist at management consultancy, Vendigital, said: “Nissan’s further commitment to its Sunderland plant is a welcome boost for the economy and job creation, but without a significant increase to battery manufacturing capacity, the UK might not be able to meet growing domestic demand for mass-market EVs, or at least not at a competitive price.

“The Faraday Institute has estimated that the UK will require 100GWh of battery manufacturing capacity by 2030 to meet the demands of the automotive industry along with other sectors, and Nissan’s latest announcement demonstrates that the pressure is on to increase capacity.

“Countries around the world are investing significantly into this industry, for example the US’ Inflationary Reduction Act aims to accelerate the move towards electrification. The UK has work to do to retain its competitive footing on the global stage, but this announcement will help to reinvigorate manufacturing capabilities and grab opportunities for job creation.

“The next big step for the UK must be to address the infrastructure and investment requirements of gigafactories. Many countries are looking to keep battery manufacturing close to EV manufacturing hubs, as moving the critical elements of the supply chain closer to each other will not only reduce the carbon footprint of EV production, but also lower the cost-to-sales – helping to keep this new technology affordable to customers.”