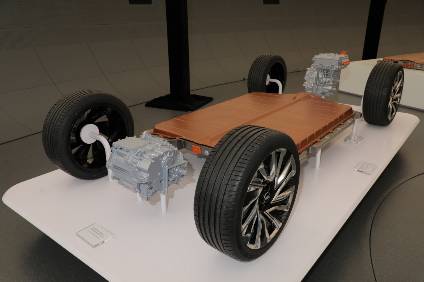

Details of the evolving tie-up between Honda and General Motors to build electric vehicles together are beginning to emerge. In April 2020, the two companies confirmed they would work together to jointly develop platforms and technologies to support a range of new battery-electric vehicles. This coincided with the reveal of the pair’s Ultium-branded EV hardware primarily based around new lithium-ion batteries co-developed with LG Chem.

Now sources within General Motors are suggesting that plans have been finalised to introduce Honda vehicles to GM’s North American assembly lines later in the decade. Beginning in 2023, a Honda-branded crossover electric vehicle is expected to join the line at GM’s Ramos Arizpe facility in Mexico, which currently manufactures the Chevrolet Blazer and Equinox crossovers. It is not yet known what similarities the Honda model will share with GM models it shares a line with, but it is expected to use the same Ultium batteries and electric motors as its American siblings.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

Further rumours suggest that another crossover from Honda’s luxury brand Acura will share a production line with the upcoming Cadillac Lyriq luxury crossover EV. These models are expected to be built at GM’s Spring Hill factory in Tennessee from 2024. Again, while there is no confirmation yet that the two models will share a platform – although it is reasonably likely – it is almost certain that both the Cadillac and Acura vehicles will use Ultium batteries and motors, following in the footsteps of the GMC Hummer EV revealed last year and due on the road in 2022.

The bold decision for Honda and GM to join forces on vehicle electrification is driven by the ever-present need to cut costs as the price of switching to electrified platforms eats into profit margins.

Neither automaker has officially acknowledged the rumours at this point. The bold decision for Honda and GM to join forces on vehicle electrification is driven by the ever-present need to cut costs as the price of switching to electrified platforms eats into profit margins. Sharing R&D costs for new batteries and associated EV components means each vehicle built costs less to make than if the two firms had done so separately. In addition, when arranging battery cell supply from the likes of LG Chem, working together gives Honda and GM more combined purchasing power than as individuals, driving component costs down and per-vehicle profit up.

In an industry battered by the impact of COVID-19, and already reeling from the costs of answering megatrends such as electrification and vehicle autonomy, this tie up is indicative of the kinds of businesses we can expect to thrive as COVID-19 recedes and EVs proliferate. Industry giants FCA and PSA have already agreed to a full-scale merger to share costs and components, while even rivals such as BMW and Mercedes are looking to share some of the costs of future technology.

See also:

Honda to use GM EV platform, batteries and factories

General Motors and Honda eye strategic alliance

GM Invites ‘Everybody In’ to EV world