Battery testing can be a costly and time-consuming process that results in many failed prototypes and wasted materials. What if there were a simpler way to test?

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

Founded with the belief that simulation and modelling can be used to assist and accelerate the development of new battery technology, leading battery data and software company About:Energy, says it is accelerating electrification through battery virtual prototyping.

By creating simulation models, the time and cost needed to bring new battery technologies to the market is greatly reduced. Moreover, it can also allow designers and engineers to compare design options in a simple interface (‘Voltt’).

We spoke to Gavin White, CEO, and co-founder at About:Energy, to discuss how the simulation technology works and highlight the benefits it provides the automotive industry.

Just Auto (JA): Could you discuss company background?

Gavin White (GW): About:Energy is a spin out company from Imperial College London and also the University of Birmingham. It’s where my co-founder and I did our PhDs. A mutual mentor suggested that we start a business together. That was almost three years ago.

The reason two universities came together is because I did my PhD at Imperial, which is very good with battery engineering. Birmingham is very good with battery electric chemistry. We brought all of that into one company.

Our core IP is measurement technology. We can measure the properties of batteries accurately. We wrapped that up into software products and created a platform where we provide a suite of data and modelling tools to help train engineers to design the battery system, create charging algorithms etc. We really see ourselves as a tool provider for people in the battery industry.

How does the process work?

We sit very deep in the technology stack. We work on advanced digital models and our batteries can encompass a few different categories.

One is thermal so you can imagine how hot the batteries get. Electrical is another – predicting the voltage of the battery. Then we have electric chemical, which models how the lithium moves inside the battery. The final one is degradation.

We did a public case study with Porsche through the plug and play Autobahn accelerator programme. On that project, we developed something called an electrochemical model. It models how the lithium moves inside a battery.

You can use models to develop fast-charging algorithms. A very simple fast-charging set of algorithms works on an iPhone. When you plug-in to charge at night, it charges fast to 80% and then does a slow charge for the remainder. What’s been proven now is if you do some very strange charging profiles, you can get even faster charge speeds. Think about pulsing the battery intensely in short bursts; you can charge the battery without degrading.

Could you explain your battery data platform; Voltt?

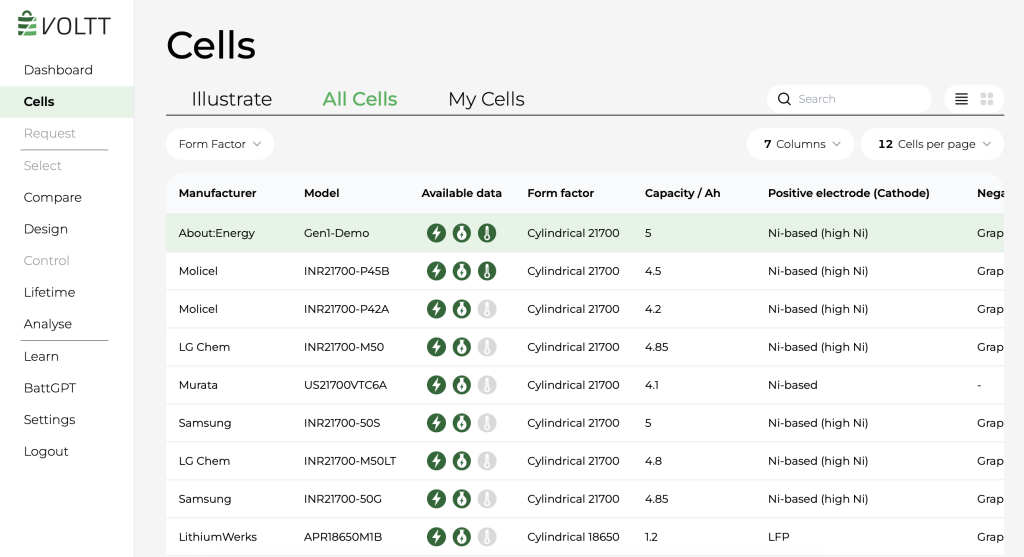

On the dashboard we have a big library of cells – from some 300 different batteries. They are from the likes of Samsung and LG. Most people don’t realise this, but even Samsung, they have around thirty different batteries on the market. These batteries are all very similar; they’re all cylindrical cells, similar shapes, sizes and capacity.

We’ve made it our goal to provide all the information you’d need on all these different cells.

Imagine you’re designing an electric scooter. What is the difference between these batteries? They can differ in say, having higher energy, power, degradation, or cost.

We’ve made it our goal to provide all the information you’d need on all these different cells. People can choose the different types of models. We started development on something called the Advanced Data sheet so the information in black would come from the manufacturer’s data sheet, and then the information in green would be the information that we measure. You can compare a Samsung to an LG, for example.

We also provide imaging results such as CT scan images of the cell. It useful for understanding how the heat transfers inside. It’s really about us providing all this data and consistently on all the different batteries that are out there.

Most people get more value from digital models, or models that can simulate production performance. Whatever engineering software customers use, like MATLAB, or Simulink, they can download the models.

We also want to provide a lot of educational material. We provide information to explain what these models are, what they do, what they can predict, and what you might use them for. Something that we have launching soon is BATGPT. You can ask it something simple like: “What limits charging speed of a battery?” Then it will answer using AI. It will give you an answer and the most important thing is it links to where it took the information from; it gives you the references and the links so you can go look up the papers and learn more about them.

This is a completely free educational tool to try and break down barriers and make battery modelling much simpler. We’re trying to build a holistic tool to help people no matter what challenges they are facing in terms of battery design, or engineering. These are tools to help build solutions.

What are the main benefits that come with this simulation approach?

If you think of designing a battery, or trying to design a car – in the real world that can mean building lots of physical prototypes that come with trial-and-error development. But if you can move that development to a computer, you can then try out many more designs, relatively easily.

Simulation is heavily used in automotive and aerospace now, for example. The problem with battery simulation is that it has not been very accurate in the past, leading to low confidence in it. So that’s where we see a big opportunity in using our measurement technology to make simulations very accurate. It then becomes much more viable to conduct the engineering in the virtual space.

Why is battery simulation not as efficient as other simulations?

In a simulation model there is a lot of mathematics, but the maths need input numbers – typically, the properties of the battery such as resistance, heat capacity, thermal conductivity. Measuring those input properties for batteries is difficult, because the batteries are, essentially, little black box devices.

The most complex models have fifty different properties you must measure. When you do experiments, it’s very hard; you only get a few different outputs like voltage, heat and current, three outputs and fifty inputs. Trying to figure out what the inputs are to get the current outputs is not easy.

Why do you feel that the measurement technology like this has not been available sooner?

It’s extremely difficult to measure these properties. Most companies or even universities have expertise in measuring most of these properties, but they take decades of research to develop. They are extremely complex, for example in trying to measure the diffusion coefficients of lithium at the nanometre level.

We really see battery modelling as being an inherently difficult problem long into the future. But we’re making it our mission to take a deep dive on measurement and modelling, to help generate both the data and tools for industry that are needed.

Some companies have built up expertise over time and niche-specific fields. It really took two universities coming together to advance this. I wish myself and Kieran could take credit for all the research, but it’s been developed over decades. We’ve been able to piece it all together into a full solution.

We really see battery modelling as being an inherently difficult problem long into the future. But we’re making it our mission to take a deep dive on measurement and modelling, to help generate both the data and tools for industry that are needed.

In the UK, there’s not a single undergraduate course that teaches specifically about batteries. I think there are only two masters courses on batteries. There’s a huge skill shortage in this area. There are people from different fields of mechanical, chemical, physics or software expertise that have to pick up what batteries are and how they work.

We really see it as our mission, our job, to train them up as quick as possible.

What are some company goals for this year?

For the company, the biggest milestone is going to be raising our Series A investment grant. We want to use that to fund increased lab capacity and get more people to really deliver on some of the big contracts we have.

It’s going to be a huge test. We’re fifteen people strong today and it’s tiny compared to other companies. We’re going through a phase of bringing in our first layer of management, using our Series A money to bring in people with a greater experience.