The battery management system (BMS) monitors, analyzes and adjusts when necessary, protecting the pack and making sure it consistently meets all requirements. BMS and battery are so intertwined that their design must happen in parallel. But how can you develop a BMS before having a real battery and vice versa? You need simulation-driven development. Design, validate, and deploy BMS-embedded software using a model-based approach in a common environment for system and software engineers. Combine realistic battery and BMS models in co-simulation scenarios to frontload verification and validation activities. And effectively achieve battery pack designs of premium performance, safety and longevity.

Many factors influence the way batteries respond. To make sure they always meet the design requirements, the BMS must continuously monitor and adjust.

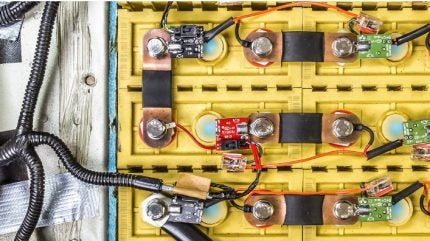

Design the battery management system along with the pack

The BMS improves battery performance by ensuring a more even charge, power and temperature distribution across cells and by preventing them from working outside their safe operating range. Its role in meeting the overall pack requirements is so prominent that the BMS must be developed along with the pack. Therefore, you need realistic battery models, holistic electric control unit (ECU) models with embedded software and co-simulation capabilities.

Develop robust embedded software

Controller software development usually comprises two levels: the platform, covering a range of applications, and a program-specific implementation. Your processes must empower this two-level approach for all software development aspects, including requirements definition, architecture definition, algorithm development, automatic code generation and continuous verification and validation. To make and maintain software secure and defect-free, you also need tools to manage and track requirements, testing scenarios and issues throughout the entire MS development cycle and beyond.

Reduce physical prototype validation testing

Even when there would be a battery prototype available for final validation and in-vehicle integration, you cannot rely on physical testing only to make sure everything works as expected for all operating points. There are just too many scenarios to cover, and you would lose a massive amount of time recharging, between or as part of measurements. Instead, you must do a vast share of the validation work virtually, based on realistic simulation models, so you can do dozens of tests in a matter

of hours.

At Siemens, we have a dedicated offering for BMS design. With Siemens Xcelerator™, our comprehensive and integrated portfolio of software and services that is accessible as a cloud-based SaaS solution, powered by Amazon Web Services (AWS), we help battery engineering teams develop the BMS in parallel with the battery pack in a common environment, using a model-based approach. By doing so, you can validate the BMS control unit and its embedded software virtually and earlier for numerous realistic scenarios, leading to substantial time and cost savings.

Efficiently develop robust and secure embedded software

Develop application-specific algorithms in an AUTOSAR-based environment that delivers architectures that meet all functional safety standards (ISO 26262 ASIL D). This platform is scalable, supports multicore configurations, and is made to execute time-critical applications.

Take a systematic approach to software development and testing

Orchestrate the entire software development workflow from requirements engineering to test cases using a powerful application lifecycle management (ALM) solution.

Set up a scalable model-based design testing framework

Use model-based system simulation to create fast-running yet accurate battery models with different levels of fidelity for various testing needs and capable of participating in model-in-the-loop (MiL), software-in-the-loop (SiL) and hardware-in-the-loop (HiL) test setups.

Design robust harness systems and predictable performance communication

Integrate electrical system and network design with architecture definition and software development, enabling a holistic virtual representation of the BMS.

Virtually verify and validate embedded software

Make the BMS defect-free before any hardware is available by doing extensive verification and validation of the actual embedded software on virtual ECUs combined with advanced battery models in automated virtual testing scenarios.