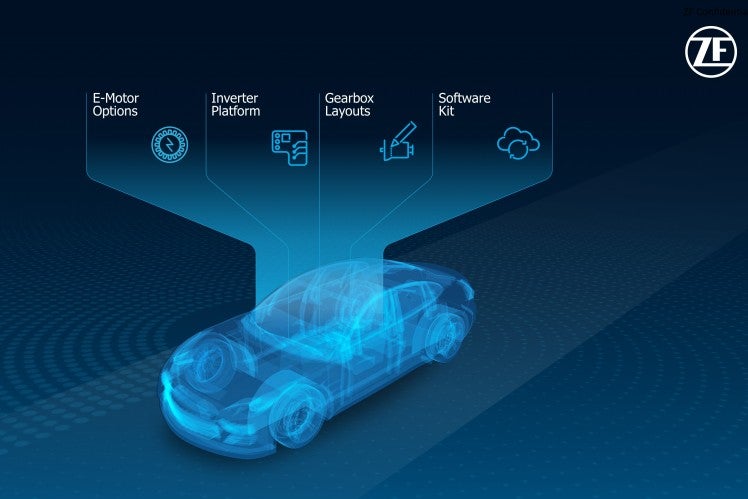

Tier 1 supplier ZF has announced a new generation of electric drives based on a modular overall concept with electric motor, inverter, transmission, and software.

“We are focusing on three basic systems that meet our customers’ main requirements, namely efficiency, performance and cost, even in the standard version,” said Markus Schwabe, product line manager electrified powertrain systems.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

“On this basis, we can optimally implement further individual customer requirements in e-vehicles of all segments.”

“The great interest of manufacturers in our products in both the passenger car and commercial vehicle sectors is confirmed by our high order backlog in the high voltage business,” said e-mobility chief Stephan von Schuckmann.

Fully integrated or separates

The new generation of e-drives offers fully integrated electric drive systems but the group will also offer the innovative components individually.

“Thanks to sophisticated internal interfaces, the new, extremely compact design allows system or component adaptations to be made with little effort. In addition, the design has very high structural rigidity, which enables superior noise behavior,” said Otmar Scharrer, head of development for electric drive technologies.

The new generation of e-drives will be available on the market as a complete system starting in 2025 but individual components will be in series production earlier.

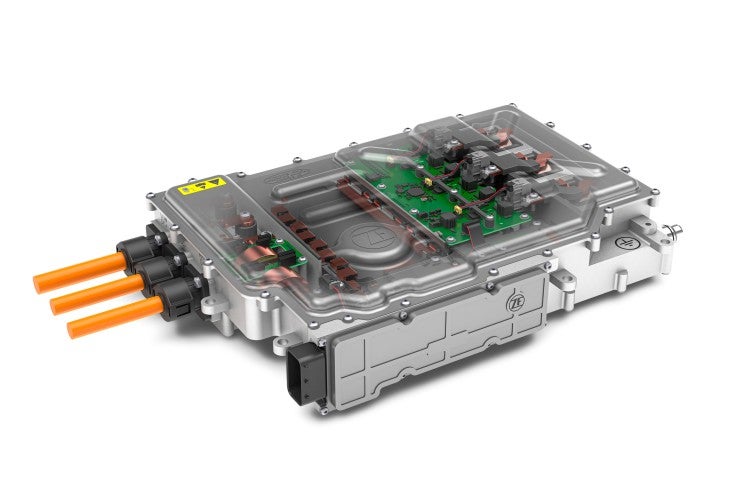

With “discrete package technology”, power electronics manage the balancing act between a high degree of component uniformity and high adaptability. The individualization takes place at the chip level: A discretely structured inverter is built with individual power semiconductor switches. This modularity offers better performance scalability than is possible with complex power modules. This requires fewer types of components than using conventional power modules.

“With our new approach to power electronics, we can serve different market requirements faster and more precisely,” said Scharrer.

With a new, highly integrated e-motor, power density gets a boost compared with current technology. New cooling allows oil to flow directly around the copper rods where most heat is generated during operation. Such highly efficient cooling significantly increases performance with the same weight and installation space. The continuous power of the electric motor is increased to up to 85% of the peak power. In addition, the use of heavy rare earths can be largely dispensed with, and the e-motor can thus be produced more sustainably. The braided winding technology developed by ZF, a further development of the “hairpin” winding, enables 10% less installation space. The winding head alone is around 50% smaller than with conventional approaches. This means that around 10% less raw material is processed.

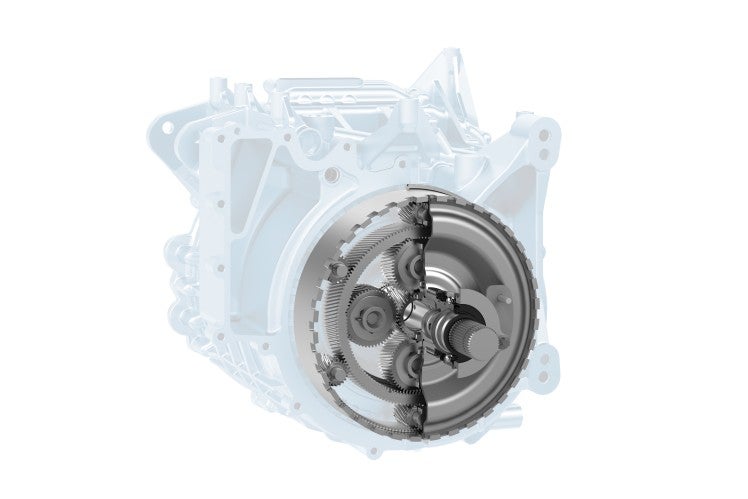

With its new coaxial reduction gearbox, the supplier, known for generation of conventional ICE automatic transmissions, has aoolied its knowledge to the next generation of electric drives. Two integrated planetary gears generate the desired axle ratio and also a fully integrated differential function.

Compared to common offset concepts, the new product reduces weight and installation space requirements without compromising efficiency, noise, and vibration.

High-voltage converters (DC-DC converters) have been introduced to play a central role in fuel cell-powered electric drives. They compensate for the low output voltage and the strong voltage drop at high load of the fuel cells. The new high-voltage converter, which was developed for both passenger car and commercial vehicle applications, has a top value of 99.6% in terms of efficiency.

The announcement was made to UK media at ZF’s new hub in Shirley, near Birmingham, opened recently at a cost of GBP70m.

The supplier employs around 2,800 people at nine locations in the UK, where six of its nine divisions operate. The new hub employs around 1,000 engineers working on R&D of smart actuators, electronics, software and controls.

The company emphasises ‘digital twins’ eliminating physical prototypes to bring new, fully tested, and productionised products to market more quickly.