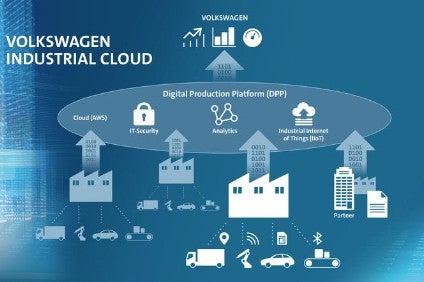

Volkswagen and Amazon Web Services (AWS) said they would develop the Volkswagen Industrial Cloud together and have agreed a multi-year, global deal to jointly carry out the project.

The cloud will combine the data of all machines, plants and systems from all 122 VW Group facilities allowing production processes to be optimised and improving plant productivity.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

In the long term, the group global supply chain with 30,000 locations and 1,500 suppliers and partners could also be integrated.

The cloud is an open industry platform which other partners from industry, logistics and sales may use in the future.

Oliver Blume, VW group production chief, said: “With our global industry platform we want to create a growing industrial ecosystem with transparency and efficiency bringing benefits to all concerned.”

Andy Jassy, CEO of AWS said: “Volkswagen gains access to the broadest and deepest cloud with the most functionality, the most innovation, the highest performance and security, and the largest community of partners and customers of any other infrastructure provider.”

The cloud will provide IT at production level for machinery, equipment and systems enabling such tasks as production planning and inventory management to be standardised and networked across 122 production plants.

Volkswagen has chosen AWS services including Internet of Things (IoT), machine learning analytics and compute services which were developed especially for a production environment and will be extended to the requirements of the automotive industry. The architecture will be VW’s new Digital Production Platform (DPP).

All group plants and external companies will dock their system architectures onto this platform which will standardise and simplify data exchange between systems and plants.

The combination of data from all plants will provide new opportunities for process optimisation including more efficient control of material flow, the early detection and elimination of supply bottlenecks and process disruptions, and the optimised operation of machinery and equipment in all plants.

Simplified data exchange will enable VW Volkswagen to provide new technology and innovations rapidly across its various locations. These include smart robotics, and data analysis functions to analyse and check shopfloor processes from plant to plant.

With the cloud-based platform, new applications, for example in IT security for shop floor systems, can be scaled up direct to all locations throughout the world.

The open platform will integrate companies from the entire value stream and build up a network of industrial partners with a database and information which can be shared.

It is also possible the cloud platform will generally be accessible to other car manufacturers.

Negotiations with major companies interested in migrating to the cloud are already in progress.

About 220 people will work on the project based at several VW IT centres as well as planned joint Industrial Cloud Innovation Centre in Berlin with support in Dresden, Munich and Wolfsburg. Work is to begin immediately and the teams have 140 projects for integration.

These include a system for tracing the transfer of goods in and outside the factory and services for the cross plant analysis of system efficiency.

The Industrial Cloud and first services and functions should be in use by the end of 2019.

VW and Microsoft extending cloud computing partnership to US and China