Renault claims its redesigned Kangoo van’s new ‘Open Sesame’ door, revealing a pillarless 1.45 metre side opening, “sets a new record”.

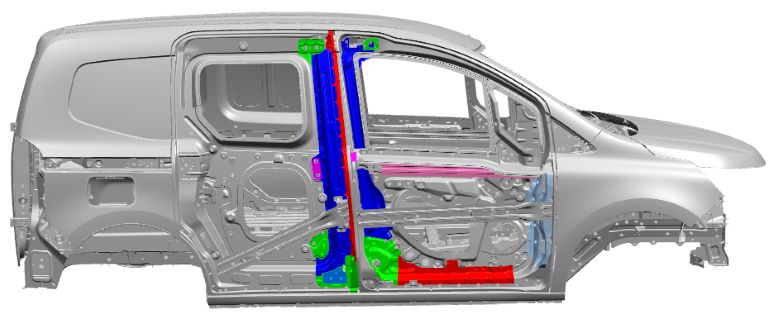

“We had to build structural components into the doors, to recreate the centre pillars when the doors are closed,” said head engineer Francois-Xavier.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

The idea was first shown at the 2011 Frankfurt show on the Frendzy concept car/van.

The engineers involved had never before designed a vehicle without a centre pillar. It required changing the vehicles architecture and repositioning all parts usually fastened to a centre pillar. Locks were moved to the top and bottom of the vehicle so the doors could be anchored to the body. The passenger seatbelt switched sides. Nine purpose built stiffeners were added to the doors so they could withstand side impacts.

The Maubeuge Plant, which has been producing Kangoo vehicles and Mercedes branded variants for 25 years, adapted its lines to handle the new door. The structure of the body was entirely reworked.

Removing the centre pillar on the Open Sesame door meant that production had to recreate it in the manufacturing process.

When the doors emerge from the stamping line, they still have a temporary centre strut to avoid warping in subsequent production processes. Eventually, on the bodywork line, the extra strut is cut off. Next, six robots add a number of reinforcement mechanisms to boost the doors’ shock resistance. Three geometrical devices monitor the doors to ensure they are the right shape (with millimetre accuracy).

In the paint shop, purpose-designed hinges are positioned on the car to hold the sliding side door frames in place.

Lastly, on the assembly line, the huge door seal is placed on the van.

Replacing the centre pillar involved adding 5kg of material and considerably more welds. A standard door has about 60 and the new system 101.