Lithion Recycling and General Motors said GM Ventures, the automaker’s investment arm, has invested in Lithion’s Series A financing round, supporting a new GM-Lithion strategic partnership agreement to pursue a circular battery ecosystem using Lithion’s advanced battery recycling technology.

This collaboration between GM and Lithion will focus on validation of Lithion’s recovered battery materials for use in the production of new batteries, and potential to acquire battery materials; joint investment in research and development for both recycling processes plus recyclability of future battery design.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

With a recovery rate of over 95% and using Quebec’s green energy, Lithion’s technology and operations will reduce greenhouse gas emissions by over 75% and water usage by over 90% compared to mining battery materials, as demonstrated by a third-party lifecycle analysis, the companies claimed.

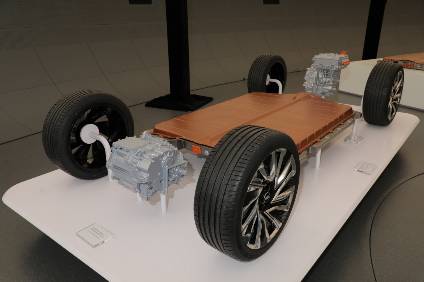

“GM is scaling battery cell and EV production in North America to reach our target of 1m units of annual capacity by 2025, and we plan to eliminate tailpipe emissions from all our new light-duty vehicles by 2035 – so we are building a supply chain and recycling strategy that can grow with us,” said Jeff Morrison, GM VP, global purchasing and supply chain.

“In Lithion’s technology, we see the opportunity to recover and reuse raw material in our Ultium battery packs, making the EVs we produce even more sustainable and helping drive down costs.”

In 2023, Lithion will launch its first commercial recycling operations, drawing on data from its industrial scale demonstration plant commissioned in January 2020.

The opening of this facility, with capacity of 7,500 tonnes per year of lithium ion batteries, will be followed in 2025 by the launch of the company’s first hydrometallurgical plant.

Lithion also has multiple facilities “in the pipeline” for the US, Europe and Korea.