Ford has announced it is pausing work on its $3.5 billion EV battery plant in Marshall, Michigan in response to what it says is its ability to run the plant competitively – as UAW strikes continue to impact the company’s operations.

Speaking to The Detroit News, a spokesperson said: “We’re pausing work, and we’re going to limit spending on construction at Marshall until we’re confident about our ability to competitively run the plant.”

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

It is unclear whether the automaker’s decision is related to the ongoing autoworkers’ strike, but the UAW has strongly criticised Ford’s actions.

There have also been concerns expressed by lawmakers in Congress over the involvement of China’s CATL in the EV battery plant. There is concern that the battery factory could facilitate China accessing US tax subsidies, which would in turn increase the automaker’s dependence on Chinese technology.

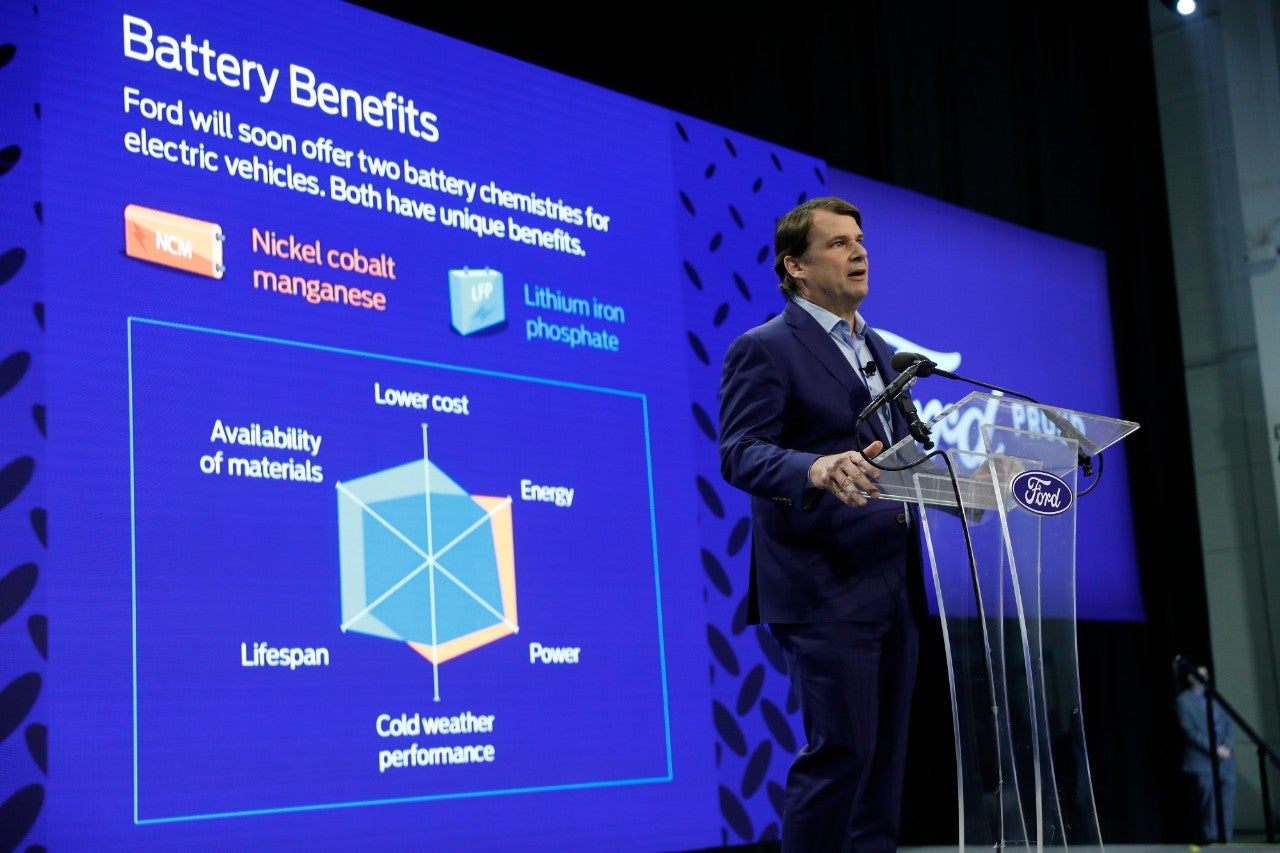

The fears are centred on Ford’s partnership in the LFP battery project with China’s Contemporary Amperex Technology Co., Limited (CATL). Under the agreement with CATL, the plant would manufacture the battery cells using LFP battery cell knowledge and services provided by CATL.

On the news that Ford was pausing construction of its Marshall EV battery plant, Shawn Fain, UAW President said: “This is a shameful, barely veiled threat by Ford to cut jobs […] We are simply asking for a just transition to electric vehicles and Ford is instead doubling down on their race to the bottom.”

Ford announced its Marshall battery plant in February of this year and said it would create 2,500 “good-paying jobs.”

The plant has been designed to build lithium-ion phosphate (LFP) batteries. Production is slated for 2026.

The automaker said that introducing LFP batteries would allow it to produce more electric vehicles and help support the company’s goal of an 8% EBIT margin by 2026 for its Model e business unit.