Saying it was the first automaker to commit to build both nickel cobalt manganese (NCM) and lithium iron phosphate (LFP) batteries in the US, last night confirmed earlier reports it would build a $3.5bn LFP battery plant in Marshall, Michigan.

The new plant would be a wholly owned subsidiary and part of the automaker’s “$50bn-plus global push to lead the EV revolution”. Initial production was scheduled for 2026 with an initial 2,500 employees.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

Under a new agreement with Contemporary Amperex Technology (CATL), the plant would manufacture the battery cells using LFP battery cell knowledge and services provided by CATL, which has operated 13 plants in Europe and Asia.

Ford said adding LFP batteries to its EV model range this year, starting with the Mustang Mach-E, and backing a US LFP battery plant were key parts of the Ford+ plan.

“This helps [us] scale more quickly, making EVs more accessible and affordable for customers,” it said in a statement.

Ford added LFP batteries were “exceptionally durable using fewer high demand, high cost materials” and would power a variety of future EV passenger vehicles and pickups.

The new plant would add about 35 gigawatt hours (GWh) of LFP battery capacity capable of powering approximately 400,000 EVs.

So far, Ford and its battery tech collaborators had announced $17.6bn in investment in EV and battery production in the US since 2019, leading to a claimed 18,000 direct jobs and 100,000 indirect roles.

The new plant would be called BlueOval Battery Park Michigan and be expandable as needed.

“We are committed to leading the electric vehicle revolution in America, and that means investing in the technology and jobs that will keep us on the cutting edge of this global transformation in our industry,” said Bill Ford, Ford executive chair. “I am also proud that we chose our home state of Michigan for this critical battery production hub.”

Diversifying and localising the battery supply chain in the countries where the automaker builds EVs would improve availability and affordability for customers while strengthening consumer demand.

Ford was working to achieve an annual run rate of 600,000 electric vehicles globally by the end of this year and 2m by the end of 2026.

Introducing LFP batteries would allow it to produce more electric vehicles and offer more choice while supporting the company’s goal of an 8% EBIT margin for Model e by 2026.

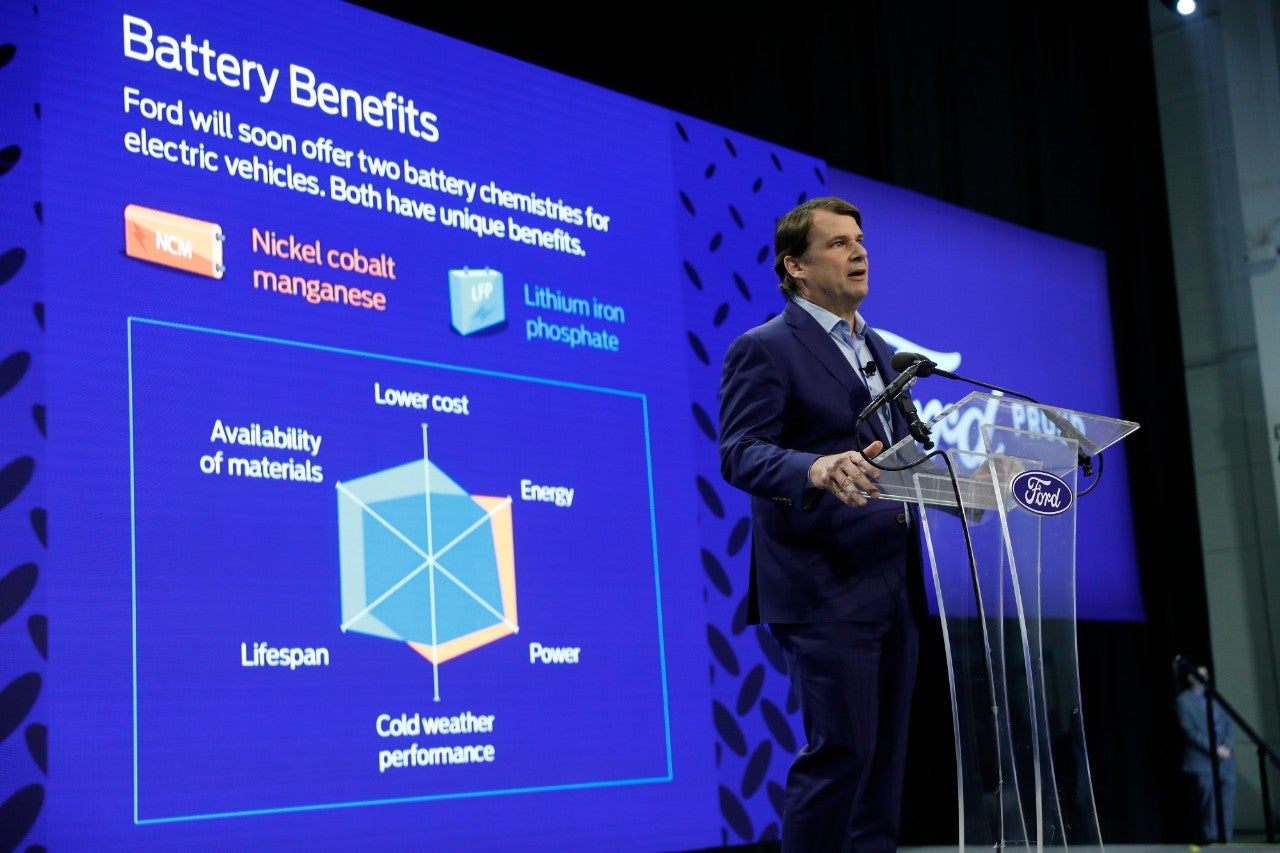

Offering LFP as a second battery chemistry – in addition to nickel cobalt manganese (NCM) – allows buyers to choose an EV with “unique battery performance characteristics most aligned with their needs.”

Offering LFP as a second battery chemistry – in addition to nickel cobalt manganese (NCM) – allows Ford customers to choose an electric vehicle with unique battery performance characteristics most aligned with their needs.

LFP batteries were very durable and tolerates more frequent and faster charging while using fewer high demand, high cost materials. This lower cost battery, at scale, would help contain or even further reduce EV prices. The LFP batteries would power affordable, EV passenger vehicles and trucks under development, most of which would be assembled in the US.

Ahead of the 2026 production start in Marshall, Ford would introduce LFP batteries for the Mustang Mach-E this year and F-150 Lightning pickup in 2024 to increase production capacity, trying to reduce delivery times.

This latest agreement with CATL adds to existing battery capacity and available battery technology made possible through a series of key collaborations including with SK On and LG Energy Solution (LGES).