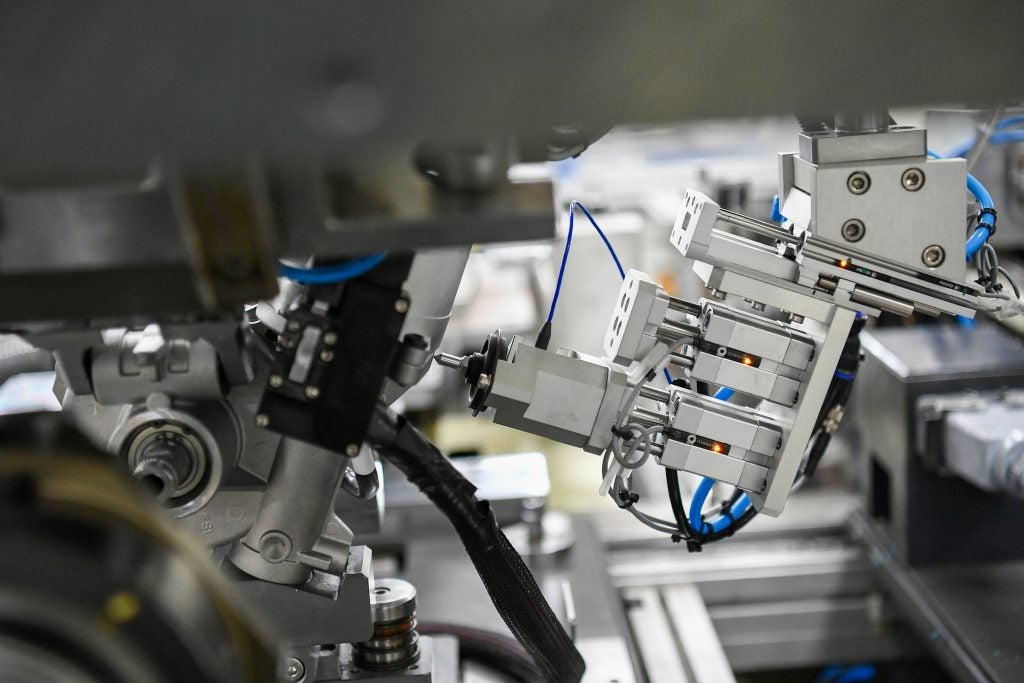

General Motors has acquired Tooling & Equipment International (TEI) a company which helped Tesla with gigacasting, the process it pioneered to cast large body parts for cars in one piece.

TEI is now part of GM after agreeing a low key deal which is a major part of the automaker’s strategy to make up ground on Tesla, Reuters sources said.

By snapping up a specialist in sand casting techniques that accelerated the development of Tesla’s gigacasting moulds and allowed it to cast more complex components, GM has jump started its own push to make cars more cheaply and efficiently at a time when Tesla is racing to roll out a US$25,000 EV, the sources told Reuters.

Tesla is now leaning more heavily on three other casting specialists it has used in Britain, Germany and Japan to develop the huge moulds needed for the millions of cheaper EVs it plans to make in the coming decade, the Reuters sources said.

Tesla is also scrambling to find another sand casting specialist to fill the role TEI performed, or even develop such crucial expertise in house to cut its reliance on outside suppliers, the sources said.

“General Motors acquired Tooling & Equipment International (TEI) to bolster its portfolio of innovations and secure access to unique casting technology,” GM said in a statement to Reuters.

How well do you really know your competitors?

Access the most comprehensive Company Profiles on the market, powered by GlobalData. Save hours of research. Gain competitive edge.

Thank you!

Your download email will arrive shortly

Not ready to buy yet? Download a free sample

We are confident about the unique quality of our Company Profiles. However, we want you to make the most beneficial decision for your business, so we offer a free sample that you can download by submitting the below form

By GlobalDataTesla and TEI president Oliver Johnson did not respond to the news agency’s requests for comment.

According to Reuters’ sources, TEI began helping Tesla around 2017 to develop the Model Y and is considered in the industry to be one of the world’s top sand casting specialists.

Since then, TEI has been involved in gigacasting mould prototyping for Tesla’s Model 3, Cybertruck and its heavy-duty Semi truck, according to two of the sources.

TEI was put up for sale last year, Reuters said.

GM had turned to TEI around 2021 to test and produce some underbody castings for its luxury $340,000 Cadillac Celestiq EV due in showrooms in 2024.

As part of that programme, GM signed a guaranteed, long term contact and TEI invested in a new dedicated production line for the Celestiq at its base in Livonia, one of the Reuters sources said.

“Bringing TEI into the GM enterprise builds on decades of the company’s own casting experience and provides a competitive advantage with strategic castings for future low volume products like the Cadillac Celestiq,” GM told the news agency in its statement.

TEI formally became part of GM’s Global Manufacturing division, which oversees all of GM’s automobile and parts manufacturing operations, on 1 July, according to a Reuters source.

“TEI will remain its own business entity with GM as its parent company,” GM said.

Two Reuters sources said GM paid less than $100m for TEI with one estimating it paid $80 million at the most. Reuters added several companies bid for TEI.

See also: Gigacasting – an engineering headache for automakers?