If you consider the above headline as press hyperbole maybe laying out the bare facts of the KPIs* of an homogeneous charge compression ignition (HCCI) engine under development by Nautilus Engineering LLC of Wichita, Kansas will help justify the hype. It boasts:

- Barely discernible emissions without a catalytic converter

- NOx zero ppm

- CO .01 ppm

- HC 01ppm

- The power of a V8 from a 4.0L 2-cylinder boxer engine

- 35% fuel economy saving

- 15-30% cost saving versus current engines

- 52% thermal efficiency

It goes without saying that automotive history is littered with companies that promised the earth in powertrain development but failed to deliver – Orbital’s two-stroke engine of the 1990s and the Scuderi split cycle engine of the 2000s spring to mind and we’ve not been without several false dawns with HCCI from the major OEMs. just-auto’s Calum MacRae met with Nautilus’s CEO and founder Matthew Riley and Mark Glasson the company’s president of Global Automotive to find out more.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

Fuel injection was developed in good faith, to stop dieseling, but what we didn’t realise back then was that we created a whole new world of inefficiency and an inability to control emissions

Nautilus was founded in 2014 to develop a high-power two-stroke/four-stroke engine for an Unmanned Aerial Vehicle. Experiments at that time led to a focused reconcentration on their HCCI concept. Riley himself confesses to tinkering with HCCI throughout his career but had never had great success with it due to the seemingly interminable control issues that plague HCCI. The basis for the Nautilus discovery goes back to pre-fuel injected engines with the habit of “dieseling” – or “run on” – the tendency of engines with a carburettor to continue to operate without spark-ignition. As Riley says, “Fuel injection was developed to stop that behaviour – in good faith – but what we didn’t realise back then was that we created a whole new world of inefficiency and an inability to control emissions that was more than we’d ever dreamed of.”

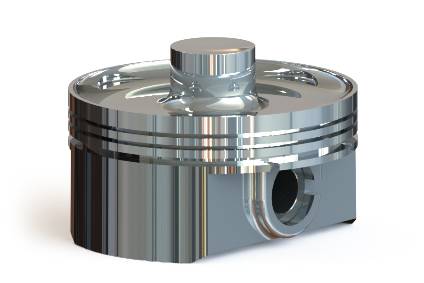

The Nautilus engine design is centred on a revolutionary one-piece piston design (there’s a hole underneath the primary piston that allows oil to jet up into it) – whereby the primary piston protrudes spigot-like from the top of the secondary piston – and into a smaller primary combustion chamber at the top of the cylinder. This design effectively compresses the premixed homogeneous intake charge at two-three times the pressure of the charge in the secondary combustion chamber. According to Riley, the reason is, “We needed a way to have ignition. With HCCI or HCI (homogeneous compression ignition) when it’s a true homogeneous mix everything in the pressure path is ignited. You have complete combustion. And the piston design gives us a primary source for auto ignition. It’s like a shotgun shell; we’re creating the primer to ignite the shotgun shell.” In this respect it’s very different to Mazda’s SPCCI engine which has its compression ignition assisted by a spark plug. With Nautilus this all happens in an engine where the compression ratio is running at 9.5:1. As Riley explains, “We’re at 9.5:1 because we didn’t want to take energy off the crank just to build up the pressure required for auto ignition.” Keeping the compression ratio low also avoids the pre-detonation issues that typically occur at compression ratios above 12:1, although in the smaller primary combustion chamber the compression ratio is elevated around two-and-a-half times. Here Riley says, “To prevent intermittent knock the intake valve draws warm air in, not cold ambient air, but it draws the warm air in across the top of the exhaust valve. Combustion temperatures in the cylinder are between 800 and 1,000 degrees centigrade”. This involves a new cylinder head arrangement with the intake valves opposite each other and likewise with the exhaust valves.

What about avoiding damage to the engine when the secondary piston becomes engaged after the high pressure disbursement? According to Riley the secret is in the blow by of EGR gas, “EGR gas blows between what little bit of gap there is, and the piston crests five to ten degree over top dead centre (TDC), which is the perfect fulcrum point to not damage the engine. We’re not pushing on the piston as hard as you would in a conventional HCCI engine when you’re igniting before top dead centre. Also, because we’re 10 degrees past TDC for the main event it means the engine runs very quietly and smoothly.”

Rather than being in HCCI mode at just part-loads, as has been suggested as a control solution by some concepts, the Nautilus engine runs HCCI throughout the speed range, “While a conventional engine’s air:fuel ratio runs at 14.7:1, Nautilus runs at anything from 14:1 all the way through to 35:1 depending on load.”

In terms of the future, Nautilus foresees a two-cylinder 4.0L engine with horizontally-opposed (boxer) cylinders. The physics of full HCCI supports larger cylinder bore dimensions than spark-ignition engines with flame propagation. As Riley says, “Engines with flame propagation can’t consume fuel/air volume within the combustion chamber before the piston pushes it out into the exhaust, thus creating high emissions. Because we have total combustion we can increase our cylinder bore and that’ll give us a very compact 4.0L two-cylinder engine with potential in the range of 400hp.”

On a per litre basis we’re going to be 20-30% more efficient, diesel would be about 20-25%, and petrol will go even higher

Being able to run the engine so lean means that substantial fuel savings are projected for the Nautilus HCCI engine compared with both petrol and diesel. “On a per litre basis we’re going to be 20-30% more efficient, diesel would be about 20-25%, and petrol will go even higher,” says Riley.

So, given all the progress so far by Nautilus what’s next? “We want to move to the next stage on the technology – taking it from 80% to 100% control over ignition, so we’re entering another round of raising capital. When we get to 100% control we’ll have a much better handle on whether we need a much simpler catalytic converter than is convention, or one at all – our aim is not to require one at all. We estimate that we’re anywhere between two and five years away from getting it into series production.” On the subject of any exclusivity agreements with OEMs the company wouldn’t be drawn, only to say anything done was subject to NDAs, with a similar picture painted for discussions with the sector’s major engineering consultancies.

What is clear, however, is that in a world of ever greater focus on fuel economy regulations, tightening emissions legislation and the backlash against diesel that there is a very significant opportunity open for Nautilus if their promising lab results can be replicated in the real world.

*Recorded by a SnapOn 5-gas analyzer testing a Nautilus HCI converted 1-cylinder engine operating in static mode on 87 octane gasoline