In 1968, the US toy company Mattel was looking to create a die-cast car range that would outperform the competition. Elliot Handler, together with his wife and company co-founder Ruth Handler, challenged the team – including a former General Motors vehicle designer and a rocket scientist – to create a die-cast car that would transform the toy market and, in time, arguably automotive design.

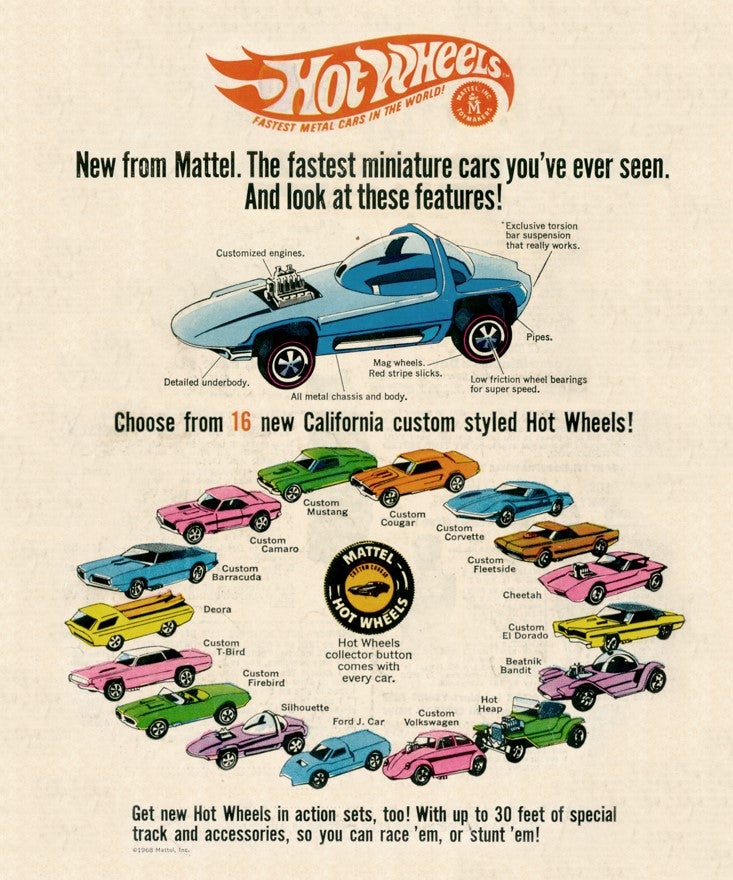

With features such as low friction axles, vivid paint finishes and striking designs that captured the car culture of the day, Hot Wheels was born, changing the segment.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

Today, that impact remains, with 16.5 Hot Wheels sold every second and well over eight billion produced since 1968. Increasingly, automotive manufacturers have sought partnerships with the brand, keen to see their vehicles in the hands of collectors of all ages.

It’s now not unusual for a car to be released in small scale at the same time as its full-size iteration and even released on the same day.

Just Auto spoke to Hot Wheels’ design manager Craig Callum, to find out more about such close relationships with OEMs, and why it works for these very different scales of the automotive industry.

Just Auto (JA): How does Hot Wheels work with OEMs?

Craig Callum (CC): Ever since the first Sweet 16 cars were revealed in 1968, the Hot Wheels brand and our team of designers have nurtured great relationships with some of the coolest and most prestigious car brands around the globe.

Today, we have licences with most of the leading OEMs as well as with suppliers such as Mobil, Falken and many more. It’s a relationship built on trust. Trust to share ideas, data and for us to inject some Hot Wheels creativity into their vehicles.

What type of cars do you feature?

Our ‘Mainline’ range includes around 450 vehicles a year including recolours, and covers everything from classic dragsters to the latest EVs, so there is always a place in our lineup for a cool car. In 2023, we had a real diversity of licenced cars, ranging from a 1990s Proton through to the latest Tesla Model Y, Pagani, Lucid Air, Fiat 500E, Volvo XC40, Porsche 911 GT3 and Ford F-150 Lightning Custom. There’s also room for the fun or fantasy vehicles too. They are the product of our designers’ imagination – so anything goes!

Is there much crossover between the sectors?

Absolutely. Just like when we started in 1968, we benefit from the crossover of talent between the two industries, with automotive designers – often from the Big Three – joining our team here in California. That’s not the only thing. By working with so many OEMs, we have built up a common trust and ability to share ideas for designs, colours etc.

It’s fair to say that just as Hot Wheels is inspired by current OEM trends, that’s also true the other way round.

It’s fair to say that just as Hot Wheels is inspired by current OEM trends, that’s also true the other way round. Walk through any OEM design studio, and I’m sure you’ll see a few of our 1/64 scale cars on the desks of the designers and engineers.

How is the design process different?

We don’t just scale down a full-size model to create a Hot Wheels. That wouldn’t work or look right. We must adjust a lot of the design elements to make the car work as a toy, to make it fun to play with, and to fit our nominal 1/64 scale.

We might change parts to make them safer, such as the wing mirrors, or parts so that they work as toys – such as enlarging wheel arches or raising the ride height. It’s an iterative process with the OEM to get these elements right for both parties. That dialogue is healthy – we are all designers, so there is a common understanding as well as trust.

That’s also the case when we have a simultaneous launch of a new car, such as we did with Lotus Emira, or that our colleagues at Matchbox have just done with the Mercedes-Benz electric G-Wagon. Both scales were released on the same day, with the Matchbox model on display at the global launch.

Your timeframe is shorter than an OEM’s though?

Our process takes around a year to 18 months. We start with some creative ideas, then move to sculpting in the digital domain – using similar tools and processes as the OEMs, before creating the model in CAD and making 3D printed prototypes ahead of the design sign-off by everyone. We’ll then test these cars on our own test track before pre-production cars can then roll off our production line ahead of entering volume production. That’s very much like the real world and given our volumes, we could well be the world’s biggest automaker!

Why are designers keen on coming to Hot Wheels when they could be working on real cars?

In a design team at an OEM, unless you reach the top, you may well end up with a narrow scope of responsibility, such as designing steering wheels or door handles. Here, our team of 40 designers do everything, even the design of the individual elements that make up a die-cast car such as the chassis, body, interior etc, a process we call ‘parting out’.

There is so much freedom for a creative person to express their ideas here.

And of course, we are doing lots of models every year, ranging from fantasy vehicles to the latest hyper-car or race car. That means there is so much freedom for a creative person to express their ideas here.

You mentioned several EVs whose models you produce such as Tesla and Lucid. Is it important to capture the automotive trends in small scale?

The automotive world is now focused on alternative powertrains. It’s therefore important and right that we feature interesting EVs such as the Volvo, Jaguar I-Pace and Porsche we have in the range right now. Cars like the Lotus Evija enable today’s kids and collectors to ‘own’ and ‘drive’ these aspirational vehicles. We can show through our toys that EVs offer performance, showroom appeal and sustainability.

Are there other ways OEMs are benefitting from collaborating with you?

Absolutely. Our talented designers may also work with OEMs to develop new exciting custom variants of their vehicles, adding that Hot Wheels flair. Here in California, we are at the heart of the current trends and fashions of not only the automotive world but a wider culture too. It can result in a completely new take on something that an OEM might not have considered.

We have run a global competition whereby you can have your car created as die-cast by winning our Legends Tour since 2018. Legends is ideal for people who have built their own car at home showing garage spirit and authenticity. Winners include a Volvo from the UK and a Mazda from New Zealand. We also offer the opportunity for OEMs to get their audiences engaged too. This year, we also partnered with Polestar for its design contest. It invites entrants to weave Polestar’s design DNA into their vision of the ultimate Hot Wheels die-cast, with the winner set to feature in our range. This is part of a wider partnership with Polestar.

There are other ways too, such as creating a Hot Wheels edition of the Chevrolet Camaro, and just last year in partnership with Mobil and Porsche, we created a scale model of the Dirtmeister 944 revealed at Rennsport Reunion 7. We first collaborated with Porsche 50 years ago, underlining that these are very long-term relationships.