German manufacturer of machine and car parts Schaeffler is set to introduce its modular EMR4 (Electronics Motor Reducer, 4th generation) electric axle drive at the upcoming IAA MOBILITY event.

In addition to this electrified powertrain solution, the company will highlight advancements in two other main areas, software-defined vehicles (SDVs) and intelligent chassis and body solutions, for the first time since the acquisition of Vitesco Technologies.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

The company said that by 2035, battery-powered electric vehicles (EVs) will become the leading drive technology.

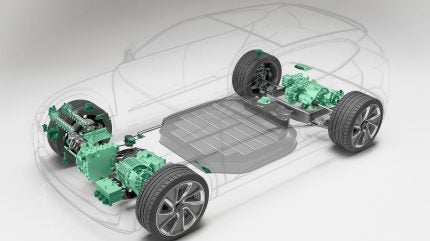

In anticipation, it has been developing a comprehensive range of electromobility solutions, which encompasses components such as power electronics, electric motors, high-voltage axle drives, thermal management modules, and electronic control units.

The EMR4 electric axle drive integrates a synchronous motor, power electronics, and transmission into one compact unit.

Its modular design ensures adaptability across various vehicle types, and it also comes in a variant that does not require rare-earth magnets.

Schaeffler E-Mobility CEO Thomas Stierle said: “The EMR4 platform is designed as a modular system, offering free configuration.

“Different inverter, reducer, rotor and stator, and housing variants enable us to deliver tailored solutions that meet the diverse performance and packaging requirements of our customers worldwide.”

Thermal management is also a focus for Schaeffler, particularly with the aim of enhancing powertrain efficiency. The company’s modular thermal management solutions are compatible with alternative refrigerants like R744 (CO₂) and R290 (propane), ensuring readiness for future regulatory changes.

Plug-in hybrids and range extenders are also a key area of innovation for Schaeffler, and the company will demonstrate an internal combustion engine specifically developed for hybrid applications, featuring damper solutions and electromechanical camshaft phasing units.

Additionally, the “Flex Fuel Sensor” will be showcased, which monitors ethanol concentration and fuel temperature for improved emissions control.

Schaeffler powertrain & chassis CEO Matthias Zink, CEO noted that the progress in steer-by-wire technologies, including the Hand Wheel Actuator (HWA) with force-feedback function.

This technology merges a magnetorheological brake with a BLDC motor to deliver steering feel while reducing reliance on copper and rare earths.

Schaeffler is also addressing the increasing complexity of vehicle architectures by developing technologies that support the transition to SDVs.

These technologies aim to consolidate software-based functions into centralised and zonal controllers, streamlining vehicle architectures and reducing wiring complexity.

In August 2025, Schaeffler introduced its Hands Free Access Sensor, which enables keyless, hands-free operation of vehicle doors, including trunks and sliding doors.