Although they have grown in popularity, EVs still create barriers for adoption for some people. Besides the price tag, range and charge anxiety are two key factors preventing some from going electric.

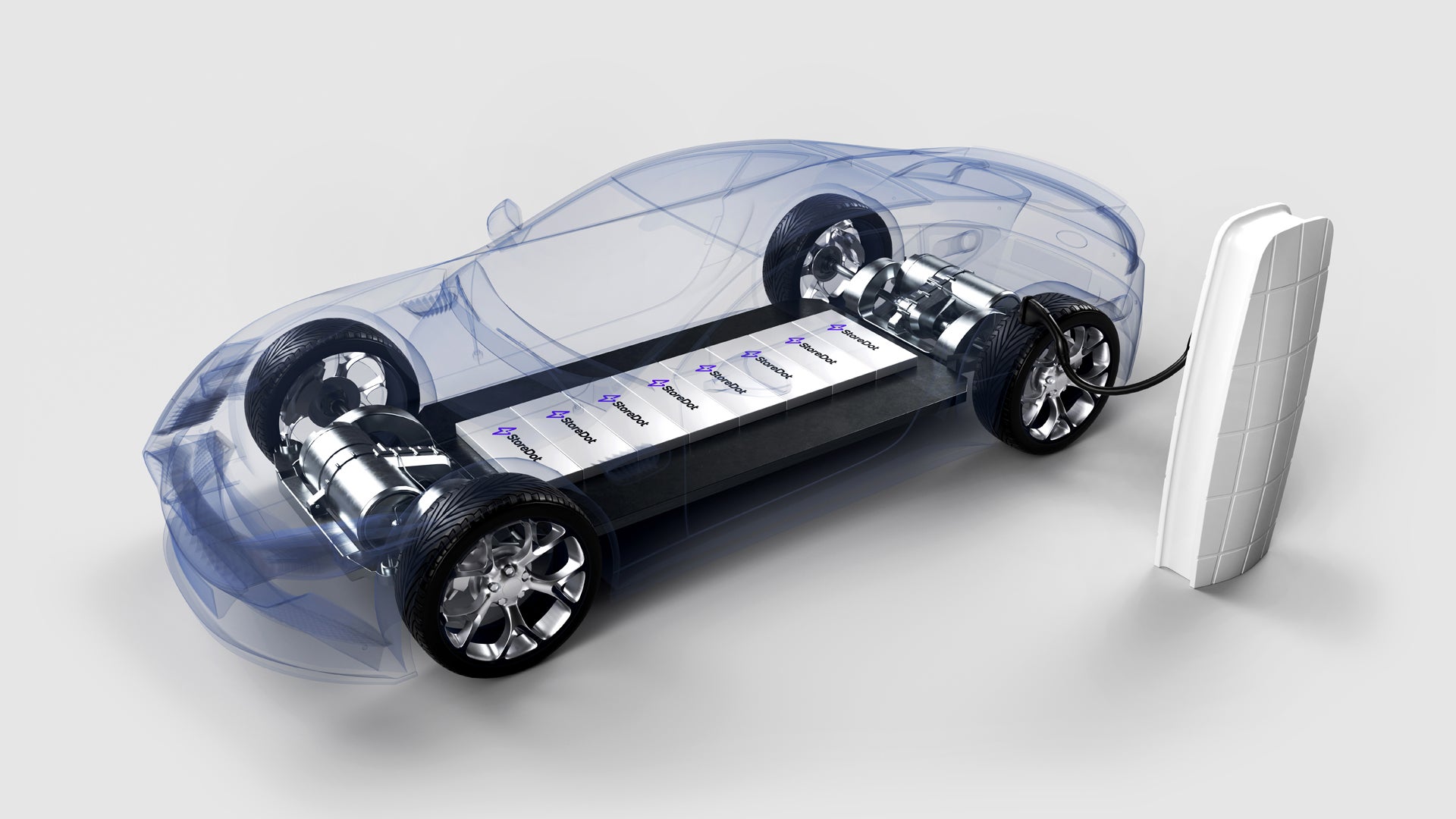

Leading pioneer of extreme fast charging batteries, StoreDot, is working towards reducing this anxiety by revolutionising the conventional Li-ion battery and redesigning it to optimise its charging capabilities. By working with AI algorithms and by using organic and inorganic compounds the company says it has made it possible to charge an EV in under ten minutes.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

To assist StoreDot on this journey, the company has partnered with VinES, an energy solution provider, and a member company of Vingroup, the largest private conglomerate in Vietnam.

The agreement follows the already announced investment of VinFast into StoreDot marking a new milestone in the cell technology development between both companies. At present the companies are preparing to introduce XFC (extreme fast charge) battery solutions for the green mobility market, including VinFast’s electric vehicles.

We spoke to Doron Myersdorf, CEO StoreDot, to learn more about this partnership and discuss the development of the fast charge batteries.

Just Auto (JA): Could you tell me a little bit of history on the company?

Doron Myersdorf (DM): StoreDot is exactly ten years old. We are based in Israel and now we also have labs in the US. We are focused on finding the solution for fast charging of electric vehicles because I believe this is the number one barrier for adoption today; it’s no longer the range anxiety, now it’s more the charging anxiety.

People are worried that they don’t reach the destination because there’s no charging station, or there’s a long line at them when they arrive, or it takes them two hours to charge. In order to solve this StoreDot is working on new chemistry of the batteries, so this includes the organic chemistry and the materials that we synthesise, the nano-technology, which is basically silicon, nano silicon which replaces the graphite in the battery, and then the design of the cell for low resistance and hypo charge.

People are worried that they don’t reach the destination because there’s no charging station, or there’s a long line at them when they arrive, or it takes them two hours to charge.

How did the partnership with Vingroup come to be?

For the last two years we’ve been in business discussions, and due diligence for their investment. About a year ago, they invested in StoreDot.

Since then, we’ve been working on the best way to incorporate fast charging into their vehicles. We’ve reached this collaboration agreement where StoreDot provides the technology of the battery and VinES provides the expertise in the manufacturing.

They have already one facility that is operational in Vietnam, but they’re also building one in North Carolina, in the US, and the plan is to leverage the technology and introduce it into the infrastructure.

What does the partnership mean for the company?

For a start-up, time to market is a key advantage. We believe that this is our fastest route to market because there’s synergy between the technology, the manufacturing and then integration into the vehicle.

It’s highly vertically integrated, almost like Tesla. Tesla, have everything on under one roof. This agreement puts everything under one roof. There’s a very fast feedback loop from the production of the vehicle to the chemistry that we all collaborate on in order to optimise the fast charging. VinES believes that extremely fast charging, like we deliver, is one of the key selling points of future vehicles.

For most of the vehicles, especially those that are in this mid-range, it’s analogous to the smart phone world; it all became very similar and now this one has a better camera, this one has a nicer design. Here it’s about fast charging and we are different and the technology that we bring is the differentiator that will accelerate the sales of the infrastructure.

What are some of the benefits of the fast-charging batteries?

My vision is that the experience of the driver eventually will be exactly how to just stop for a few minutes and you get enough range to get to your destination. In order to do that two things need to happen.

One is that the battery needs to have a chemistry that is capable of taking the high power in minutes, in a safe way and with enough energy density, sufficient range.

The other part which we are working on more with our partners is the infrastructure. You need enough charging stations in order to be able to do that. We already see 350 kilowatts coming from Electrify America, Charge Point, and also BP was one of our key investors. It really changes and depends on which vehicle you have; a lot depends on the status of the battery and where charging stations are.

My vision is that at the end of the day, this experience it will be a mixed model. You can charge on the street, you can charge at home, you can charge while you shop, if you are on a trip, and if you need the range quickly you will get it in a few minutes, so it doesn’t stop your trip.

Looking at the current infrastructure, do you think the UK Government EV goals are achievable?

I think we can look at the China as a model of how government support and regulation actually pushes the infrastructure deployment. It really is chicken and the egg – if there are not enough stations you won’t have enough vehicles on the road.

It really is chicken and the egg – if there are not enough stations you won’t have enough vehicles on the road.

Look at the adoption rate: it’s doubled in China. This is mostly because of the infrastructure that has become available. So the conclusion is that if we want to meet the goals it has to come with much more investment from governments in the right infrastructure.

What would you say to people who are maybe still hesitant in trying an EV?

I think for those who are still in doubt EVs are happening; they’re happening big time and it’s happening faster than we all thought. Carmakers need to really change their mindset; they don’t want to have a Kodak moment. They really need to adopt and change their mindset to adopt new technologies faster.

We see that with some of the OEMs testing programmes, they might take years, so you’re potentially missing out on new technologies. Traditionally this industry is very conservative in approach, especially when it comes to new technologies and batteries, but the new rules of the game in order to move faster have more of a start-up mentality to quickly adopt these new technologies.

What are the next steps and goals for the company this year?

The challenge right now is in execution of the supply chain in manufacturing. We are working with several partners on the manufacturing side, one is VinES, another is Italvolt. We have an agreement in China with one of our investors called EVE Energy.

So we are looking at the global footprint of manufacturing. We want to be very close to where the vehicles are actually being manufactured. You don’t have to ship these batteries too far; there’s also a carbon footprint for shipping those.

In three years’ time we want to be operational in at least three continents with the manufacturing of this technology. Some of our investors that we’ve announced are actually tracing the raw materials from the source. We’ve already implemented a programme that would allow us to trace the carbon footprint and to optimise where we source materials and how they are being implemented and then eventually how they’re being recycled.