In this interview, Matthew Beecham talked with Guillaume Hebert, EGR product development manager, Nigel Seeds, senior application engineer, and Richard Armsden, senior application engineer, about Visteon’s powertrain cooling system products and innovations.

just-auto: What are the factors driving the automotive powertrain cooling sector?

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

Guillaume Hebert: The main drivers are:

- Cost – there is always a significant driver for cost reduction in order to remain competitive in the market place. Rarely will OEMs pay a premium for better technology.

- Fuel consumption – there has been significant attention recently amongst OEMs to reduce weight as a means of reducing fuel consumption, primarily due the high cost of fuel as well as increasing customer awareness of the associated environmental issues. Lower weight also impacts positively on meeting legislated emission requirements.

- Packaging – front-end styling (including reducing the vehicles drag coefficient) and pedestrian impact legislation are also drivers for more effective/efficient heat exchangers that reject the same amount of heat from the same or smaller package volume.

just-auto: Demands on powertrain cooling product performance are continually increasing. In addition, automakers expect economical solutions that help reduce emissions from cars and trucks. With these demands in mind, how have you responded?

Guillaume Hebert: Using EGR coolers as an example, Visteon has developed an innovative solution for applications between the Euro 4 and Euro 5 emission standard level which incorporates a Visteon patented concept.

The main benefits of Visteon’s U-bend EGR coolers are:

- 60% weight saving between Euro 4 and Euro 5 EGR cooler

- Package reduction

- Cost reduction by 20%

- Efficiency increase by 20%

- Easier to integrate

Picture: Visteon’s “state of the art” EGR cooler for Euro 5 emission standard: U-Bend EGR cooler concept

Guillaume Hebert: For the Euro 6 emission standard, expected to be implemented in 2014, Visteon is developing further innovations which utilise more advanced technologies to further improve the effectiveness of our components in terms of weight, performance and cost.

just-auto: As you know, packaging is becoming tighter in the vehicle front-end resulting in the requirement for more efficient heat exchangers. How have you responded to that?

Nigel Seeds: Visteon has optimised its fin and tube geometry to increase heat dissipation per unit core depth enabling weight reduction, vehicle package reductions and giving an increased output for a smaller package. The reduced core thickness also leads to lower airside pressure drops allowing low power cooling fans and less electrical load. All of these are key factors in helping reduce overall vehicle weight, improving fuel economy and reducing emissions.

A good example of the success of this activity is our 10 mm radiator core recently launched in the Ford Fiesta. This replaces the significantly deeper core found on the previous model, reducing package space and component weight. This radiator has the smallest core depth currently in production on a passenger car and can be up to 25% lighter than a competitor’s equivalent product.

just-auto: I guess other changes regarding the increasing pressure cycle has led to design changes to the radiator itself. Is that correct? What changes have occurred there?

Richard Armsden: Standardised and enhanced designs have been refined so products can withstand the increased component durability requirements:

- Design changes to tube technology using folded tubes in place of welded tubes whilst maintaining thin material gauges.

- Extensive use of up front analysis tools (FEA and mould flow) has led to improved crimp geometry and tank design.

In addition to the drive for higher pressure cycle resistance we have also seen increased interest in thermal shock resistance of radiators. Specifically, Visteon has developed and patented two technologies which we believe give us a competitive advantage.

The first we call a trapezoidal header: The joint between the header and the tube is generally the area of weakness for both pressure and thermal cycle tests. Illustrated in the graphics below, a normal header is flat and the highest stress regions are concentrated around the nose of the tube. The trapezoidal form moves the highest stress away from the nose and distributes it more evenly across the tube to the header joint, significantly reducing the maximum stresses seen in the joint. The result is a more robust joint which will extend the life of the part in service.

The second technology we call ‘strong fin’. This is directed more towards pressure cycle testing, providing more support to the tube by reducing deflection in the tube itself and, as a result, reducing the stress. The extra strength is obtained by an additional form in the fin [as shown in the diagram]. Adding form to a flat surface significantly increases its ability to resist compressive forces, and that is the essence of the concept.

Patented and innovative solutions like the Visteon’s trapezoidal header and strong fin design enable Visteon to deliver robust and lightweight solutions meeting the ever-increasing customer demands.

just-auto: In terms of materials used in the radiator, are you seeing more calcium chloride for plastic radiator end tanks? Is this a trend and, if so, what triggered it?

Richard Armsden: In certain markets, e.g. North America, Asia and Russia, it is common to see calcium chloride being used as grit on the roads during spells of cold weather. Calcium chloride is more effective than sodium chloride at de-icing roads but it has the disadvantage of being more corrosive. It is also more aggressive at penetrating the polyamide and destroying the hydrogen bonds in traditional Nylon 66 used for the plastic tanks on radiators.

There has been a drive from the vehicle manufacturers to increase the resistance of the tank plastics to be more resistant to this chemical, certainly in the affected markets. This has been picked-up by the plastic manufactures who currently offer blends which are more resistant to this attack – but are more expensive. With the automotive industry looking for globalization, i.e. the same radiator/vehicle being sold in all markets, this can drive cost into markets where the more robust material is not required.

It is possible to slow down the attack from calcium chloride by design; avoiding areas for water to pool on the surface of the radiator tank reduces the exposure time to calcium chloride in solution and thereby extend the life of the component.

just-auto: As we understand it, the key trends in the engine cooling sector are turbocharging and EGR. In what ways have you addressed the trend for two stage turbocharging applications?

Leo Somhorst: We have not seen a big impact on the way we tackle charge air cooling over single stage boosting. The trend for higher boost pressures and therefore higher charge temperatures, has resulted in requests for charge air coolers with higher performance. As with radiators we continue to develop our global portfolio parts which have optimised fin and tube geometries to increase heat dissipation per unit core depth.

We have seen in recent years an increase in supercharger use on gasoline applications. We have developed a range of water-cooled charge air coolers, both integrated into the intake manifold as well as standalone products. Multiple coolant passes with optimised low temperature radiators in the cooling loop have helped us deliver optimized solutions to satisfy the heat rejection levels required.

just-auto: In what ways does the EGR impact on the engine cooling system? i.e. for instance, is there a need for additional engine cooling due to the load the EGR puts back into the engine coolant.

Guillaume Hebert: Visteon offers vehicle manufacturers powertrain cooling capabilities:

- System performance prediction and associated testing

- Supply of all exchangers components from a single source.

The latest generation of optimised Visteon radiators are able to provide enough heat exchange to compensate for the extra heat brought to the loop by the EGR.

Additionally, a low temperature circuit can be included in the system (using a separate low temperature radiator) which can also be used to cool the EGR as well as a water cooled charge air cooler where appropriate.

Picture: Visteon Powertrain Cooling portfolio

just-auto: I guess the need to realize cooling of the EGR, either for emissions benefits on a diesel engine or fuel economy improvement in a gasoline engine, has a significant impact on the cooling system. How do you achieve that?

Guillaume Hebert: During development projects with a vehicle manufacturer, Visteon has established that the benefit for cooled gasoline EGR can be up to 9% fuel efficiency.

just-auto: Although hybrids have not really created a substantial change in the heat transfer philosophy of the engine, has this technology created the need for additional product on the electronic side of things?

Guillaume Hebert: On hybrid and electric vehicles, we can identify a number of different cooling needs:

- Battery temperature stabilisation: This can be addressed through a Visteon developed Battery Chiller in conjunction with the vehicle air-conditioning system

- Multipass heat exchangers can achieve the required coolant out temperature to support the requirements of the electric motors and associated controllers

just-auto: Generally speaking, in respect of fuel economy, is there a trend toward more use of electronics to try to more closely monitor engine temperature for maximum efficiency? i.e. perhaps using electronic thermostats and electronic water pumps to completely take control of the heat rejection itself. But I guess there is always a trade-off the carmaker must make between adding weight and cost (through electronics) and saving fuel.

Guillaume Hebert: There was a lot of interest in the industry for electronically controlled cooling systems five or so years ago. Visteon has previously demonstrated a system on both a petrol and diesel application. The system includes an electronic valve, electric water pump as well as a control model and associated software. Fuel consumption benefits of up to 5% were demonstrated but there was only limited interest at the time from the vehicle manufacturers – primarily due the additional cost to the vehicle associated with the required hardware.

Another Visteon developed technology is our Exhaust Heat Recovery System (EHRS)

- This technology uses the heat from the exhaust to warm up the engine and/or gearbox oil faster from a cold start so as to reduce friction (and consequently fuel consumption) as well engine emissions during this important part of a vehicles drive cycle.

- Visteon is a development leader in this field. The market feed-back indicates that this kind of technology could grow very fast in the next 2-3 years.

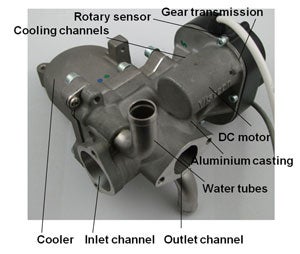

Picture: Visteon developed EHRS prototype

Visteon has also developed a fully electronic EGR by-pass valve, which is fully proportional – current EGR by-pass valves enable only two positions: fully open or fully closed. With this electronic proportional system, the EGR outlet temperature can be controlled and optimized to maximize emission reduction.

Picture: Visteon Proportional Electric EGR By-Pass Valve

just-auto: With pedestrian safety laws swinging into force in Europe, how does that impact on engine cooling system design?

Richard Armsden: In addition to our thinner and smaller radiators with increased output, we have developed fastener free mounting strategies that will nest the heat exchangers within the module creating slimmer modules to help with the packaging requirements the safely laws bring. A secondary benefit of this is the reduced requirement for sealing between the components to aid the efficiency of the heat exchangers and minimize by-pass or re-circulation.

In addition, Visteon has developed snap-fit breakable pins for low speed impact allowing the complete cooling module to move backwards in the event of a vehicle crash. As well as being a safety feature, it has the additional functionality to allow the complete cooling module to be reused after the impact. This reduces the time and amount of parts need to repair the vehicle and also helps with reducing the overall insurance rating.

just-auto: The popularity of diesel engines in the European market coupled with the new emission standards is presumably causing new developments in charge air coolers. Any observations there in terms of what is happening with charge air coolers? And how has Visteon responded in terms of innovations?

Leo Somhorst: In order to meet the Euro 5 and Euro 6 emissions legislations, OEMs are increasingly using low pressure EGR , often in combination with high pressure EGR. For low pressure EGR the exhaust gas is taken post particulate filter. This ‘cleaned’ exhaust gas is then fed back into the inlet of the turbocharger. Low temperature EGR enables higher concentrations of EGR to be used to tackle the more stringent future emission requirements due to improved mixing with the fresh charge.

In addition to offering solutions for both high and low pressure EGR cooling, we have been developing charge air coolers that are corrosion resistant to the corrosive exhaust gases that pass through them.