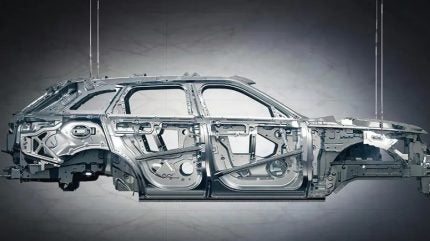

Light-weighting is a key area of focus for many OEMs due to key outcomes on fuel efficiency and vehicle performance.

British supercar manufacturer, Gordon Murray Group, is taking the concept of lightweighting one step further by creating a new generation of ultra-lightweight, environmentally friendly vehicle structures.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

The project named ‘Project M-LightEn, (Monocoque architecture – Lightweight and Low Energy) aims to create a new vehicle monocoque architecture that is lighter and stronger, alongside being 50% less carbon intensive in three years.

With a goal of achieving enhanced performance through further weight reduction, the process aims to enable future Gordon Murray Automotive vehicles to achieve the lowest lifecycle carbon footprint of any supercar.

We spoke to Jean-Philippe Launberg, strategy and business development director at the Gordon Murray Group, to learn more about the environmental benefits of lightweighting vehicles, and what this project aims to achieve.

Just Auto (JA): Could you tell me about ‘Project M-LightEn’?

Jean-Philippe Launberg (JL): It aims to give us solutions for future portfolio vehicles. We always need to be innovating. One key area for us is lightweighting, which gives a distinctive feel to the vehicles and dynamics.

The best way to do that is to find new materials, new manufacturing processes and new design methodologies. That is what this project aims to do. The project aims not to deliver one specific vehicle, but a set of solutions that we can apply to a portfolio of vehicles that we have already defined internally. It’s what’s going to be underpinning those future vehicles from a structures point of view, that’s what the project is about.

Every time there’s a new technology, there’s always a bit of a challenge in the auto industry to get it out there. If you are a large, global OEM, there’s only so many new things you’re willing to try, because there are a lot of investments which have been made.

For us and our model of making roughly 100 vehicles per year, (and not always keeping something in production for a very long time), this allows us to have a faster cycle and better opportunities to work with other companies, which are our partners, to come in and apply something in production, which can then be extended into the wider automotive world.

We see ourselves as having a role to play in the wider industry by being the conduit for some new solutions.

The project aims to be 50% less carbon intensive – how will this be achieved?

Our future cars will be a hybrid of composites and aluminium structures; this has started already with the T.33. We use virgin aluminium in this project and we will be trying out an aluminium structure which is more than 80% post-consumer scrap content. I have about 100 kilos of Nespresso pods in recycling bags on the floor of my office, which I plan to make the first one out of.

We’re taking window frames, Coke cans, Nespresso pods; the UK has a lot of aluminium waste, but it doesn’t get reprocessed in the UK, it goes overseas. We will use at least 80% recycled aluminium from consumer scrap, and through some projects which are still confidential. We will scale that up.

Something else we are looking at is embedded carbon. On many vehicles there’s a lot of embedded carbon in carbon fibre. We use a lot of it, and most sports cars use a lot of it, and that’s a lot of the footprint that is in the manufacturing phase. One of the points that we want to do with ‘Carbon 360’ (which is the composites partner in this program), is to use techniques to apply carbon fibre only where a component really needs it, where the stresses are higher.

You can tune the amount of carbon fibre, its orientation, and how it’s applied inside this one specific component, instead of having a blanket use approach. This is called tailor fibre placement. That way we reduce the amount of carbon fibre, which has a lot of environmental impacts, and we also have a strong effort to reduce the waste in producing carbon fibre.

It’s like cutting fabric for clothing, there’s always waste. We are trying to minimise that waste, to get it as close to zero as we can.

All that energy, which is in the waste, if it’s going to be reused recycled later on, you still have to spend energy in the first place. These are the two points that from a composite point of view we are working on. We also want to avoid any well welding, because that’s energy intensive, and replace that with a high level of structural bonding.

From a methodology point of view, we will be embracing all three partners’ generative designs. We’re going to use machine learning tools to do hundreds, if not thousands of system optimisations, and generate the design rather than starting from a big piece of aluminium or metal, and then subtracting from that – which has been the norm of the industry so far. We want to generate it from a computer algorithm, and let that help us generate new designs, only putting materials into use where required.

How does lightweighting benefit the environment?

You usually don’t think that people that manufacture V12 sports cars care much about the environment, right? The fact is, though, we do. We don’t make a big fuss out of it; we don’t advertise it, but we do.

We intended to not only pursue lightweighting, but also look at how we can align it and team it up with a reduced carbon footprint. These are vehicles which do not drive large distances in their lifecycle. It’s way different from, say, an Opel/Vauxhall Corsa, for instance. The majority of our vehicle’s impact, CO2 footprint-wise, is going to be from the factory phase.

You usually don’t think that people that manufacture V12 sports cars care much about the environment, right?

We have thought about can we reduce weight, which helps us with dynamics and driver engagement, and at the same time use it to decrease the CO2 footprint.

We have a pretty good indication that we are already amongst the cleanest supercar makers as a result of our extreme light-weighting. It uses less composites, less aluminium and less petrol.

It’s amazing what mileage you can get on a T.50 if you stick to the 70 miles per hour limit on the motorway. We’ve seen some amazing figures, but we shouldn’t stop there.

It’s also about making our owners feel better about themselves and we feel as a company that we are helping to sustain this niche of the industry, an essential part of it, for the longer term.

It’s also very debatable how clean an electric supercar really is. Now, obviously, when they drive, there’s no pollution, but because they tend to be twice as heavy or more, that manufacturing phase is very energy intensive indeed, and it ends up defining their whole footprint, their life footprint.

What do you hope others in the industry will take from this project?

I think one of the things we’d like to inspire is that there’s not one solution for everything. The solution doesn’t have fit to the specific objective that you have in mind, and the type of vehicle you plan to use it in.

It’s very easy to try to either legislate a solution or to assume that the same solution should be used all the way from off-highway vehicles to a sports car. What we want to show is that you can pursue new solutions that will deliver the intended impact, at a very high level, but they can still be supportive of your company’s differentiators as well.

We have very strong indications that if we were to at least sit with the technology existing today, if we were making an electric supercar, it would actually have a higher footprint than an equivalent ICE one, because of that heavy CO2 manufacturing phase. If you are only driving 1,200 to 1,500 miles a year on average, you know will never offset that initial hit.

This project is also very interesting because it’s very powertrain agnostic. We can use the solutions from M-LightEn on vehicles of very different shapes, and in all powertrain types. There’s no reason why it couldn’t become an EV. The solutions can be applied to an EV, and I actually do expect that they will.

They can still underpin a V12 petrol car as well, and anything in between, any hybrids in between, and that’s all part of our future portfolio.

What is the main goal of this project?

We will improve our footprint, and introduce new methodologies into design and engineering, through machine learning, and generative design. We will be using all the solutions we developed and I think we have a good road map to get there, to make it all worthwhile.

We will improve our footprint, and introduce new methodologies into design and engineering

We will use all those solutions, then we hope that during the program, our partners will already start to find applications they can utilise. They’re fine to do it and they’re encouraged to do it.

This is a jointly generated IP, and they should explore their share of the IP as well. We think we can leave a little bit of impact on the industry as a whole.

Project M-LightEn will enable decarbonisation across the wider automotive industry by shortening and de-risking the path to market for innovative new materials and processes.