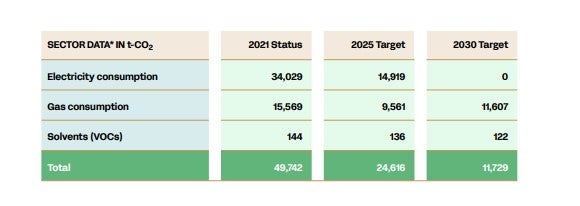

- TMD has achieved 46% reduction in tonnes of CO2 for Scopes 1 and 2 compared to 2021 baseline.

- In 2024, TMD Friction utilised 52% green energy from its suppliers, edging closer to its goal of accessing 100% renewable energy by 2030.

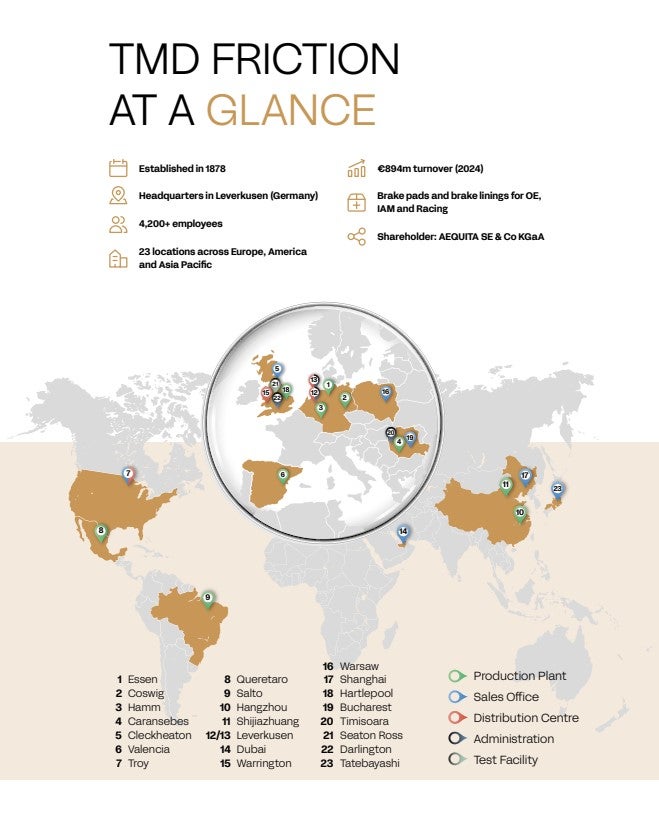

TMD Friction, a global manufacturer of brake friction solutions, has published its latest ESG Report, which summarises its environmental, social and governance progress for 2024.

In the report, the manufacturer reveals it has achieved a 46% reduction in tonnes of CO2 for Scopes 1 and 2 relative to its 2021 baseline. This has been achieved through various initiatives across the manufacturer’s operations, from greener energy and more efficient processes to better waste management and product development.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

TMD also says it has already surpassed its ambitious 2040 target for removing volatile organic compounds (VOCs) from its products, achieving a 31% reduction in 2024, significantly exceeding its goal of 20% reduction by 2040. This has been achieved in part by investing in new technologies and developing a VOC-free adhesive.

With a starting base from 2021, TMD Friction’s Sustainability Roadmap 2040 sets clear environmental goals to reduce emissions across Scope 1, 2 and 3 (see explanatory note below), focusing on a ‘robust strategy for the short-, medium- and long-term’.

Lynn Edwards, Vice President of HSE and Sustainability at TMD Friction, said: “As a global leader in brake friction manufacturing, we are committed to driving change and pioneering a more sustainable brake industry. Every day we work towards making these smaller improvements to achieve our bigger goals, but it’s only by seeing it all together in our yearly ESG Report that we can truly appreciate how far we have come.”

Increasing green energy

In 2024, TMD Friction utilised 52% green energy from its suppliers, edging closer to its goal of accessing 100% renewable energy by 2030. The manufacturer was also able to reduce energy usage by 3% through initiatives such as upgrading or replacing older equipment, improvements to compressed air leakage management, and optimisation of heat recovery at the regenerative thermal oxidizer (RTO).

The investment in specialised energy management software has enabled TMD Friction to analyse energy consumption data online and achieve transparency in the breakdown of energy costs according to their source.

Based on the data provided for 2021, the total Scope 1 and Scope 2 CO2 emission equivalents of the TMD Friction business amounted to approximately 49.5 t/CO2. This amount includes Scope 1 (direct emissions resulting from gas combustion, solvent use etc.) and Scope 2 emissions (indirect emissions e.g. those resulting from purchased electricity) only.

In 2021, approximately 30% of the CO2 emissions were related to consumption of natural gas, which is mainly associated with the operations of the ovens (scorching, curing) and the afterburner units that are required for treatment associated with VOCs.

Electricity accounts for approximately 69% of TMD CO2 emissions. Compared with this, emissions related to VOCs and company vehicles are of minor importance, the company says, relating to only 1% of TMD Friction’s greenhouse emissions.

People, packaging and purpose

TMD Friction says it encourages employees to be part of its sustainability journey, actively encouraging them to identify, propose and lead initiatives that create a positive impact via its Kaizen Programme. In 2024, there were 162 global projects led by employees, nine of which were sustainability focused. The nine projects delivered combined savings of more than €631,000 across its operations.

One key Kaizen project focused on making the company’s packaging more sustainable. The objective was to find alternatives that reduced environmental impact but maintained functionality. Various options were considered but the clear winner was a honeycomb structure made entirely from recycled paper. During testing, it performed well in all applications. The new innovation will replace 19 different types of foam, marking a crucial milestone in TMD Friction’s sustainable packaging improvements.

David Baines, CEO and President of TMD Friction, said: “We couldn’t achieve such ambitious goals without the commitment and passion from our employees. Through initiatives like our Kaizen Programme, they are making a real difference to our operations, proving that meaningful change happens when everyone is empowered to contribute to our sustainability journey.”

Improving waste management

TMD Friction has big targets to reduce landfill waste by 20% in 2025, 50% in 2030 and finally by 70% in 2040. By employing its 5Rs strategy (refuse, reduce, reuse, repurpose and recycle), it is enabling targets to be met, it says. In 2024, TMD Friction increased onsite recycling by 14%. Individual regions also implement their own locally focused sustainability initiatives to improve operations. TMD Mexico, for example, donates its waste wood to a local company specialising in designing and crafting furniture from reclaimed wood. At the Mexico facility in 2024, 16 tonnes of wood was recycled into sustainable furniture, preventing its final disposal in landfill.

2025: A pivotal year

Following a successful 2024, 2025 is a target year for TMD Friction as part of its Sustainability Roadmap 2040. In 2022, specific improvement goals using 2021 as the baseline were set. The targets are ambitious but achievable, the company says. In 2025, TMD Friction will be working on exploring further renewable energy sources, eliminating critical substances, and increasing the use of recyclable packaging.

Note: Scope 1, 2 and 3 emissions

Scope 1, 2, and 3 emissions are categories that help companies measure their total carbon footprint. Scope 1 covers direct emissions from sources the company owns or controls, like fuel burned in company vehicles or factory boilers. Scope 2 includes indirect emissions from purchased electricity, heating, or cooling that the company uses but doesn’t generate itself. Scope 3 encompasses all other indirect emissions throughout the company’s value chain, including suppliers, business travel, employee commuting, and how customers use and dispose of the company’s products.