Sodium-ion batteries (SIBs) have emerged as a potential alternative to traditional lithium-ion batteries (LIBs) for automotive applications. SIBs are at the forefront of the news, overtaking SSBs (solid-state batteries) as the winner in this week’s list of ‘ground-breaking technology advancements. But we have been aware of SIBs for some time. The surprising element is that much of this news comes directly from the manufacturers, unlike SSBs where news about developments tends to revolve around unscalable one-off cells confined to laboratories.

So, what are SIBs and how do they differ from incumbent BEV (battery electric vehicle) cells?

Just like LIBs, SIBs contain an anode, cathode, separator, and some form of liquid electrolyte. However, rather than a lithium (Li) charge carrier, sodium (Na) is used. In addition, both anode and cathode can be made of aluminium, unlike LIBs that require more expensive copper as a current collector in the anode.

Key pros and cons of SIBs:

Pros:

- Sodium is one of the most abundant elements on Earth, making SIBs a more economically viable choice compared with LIBs that rely on constrained lithium availability. Sodium’s less precarious supply enables potentially lower production costs, making SIBs an attractive option for mass-market battery electric vehicles (BEVs).

- SIBs offer improved safety compared to LIBs. Sodium is much less chemically reactive than lithium, reducing the risk of thermal runaway or fire hazards associated with lithium-based batteries.

- SIBs have a smaller environmental footprint compared to LIBs. Lithium extraction can be environmentally damaging, involving extensive mining and chemical processing. Sodium extraction, on the other hand, is more sustainable, reducing the ESG impact associated with BEV battery production.

Cons

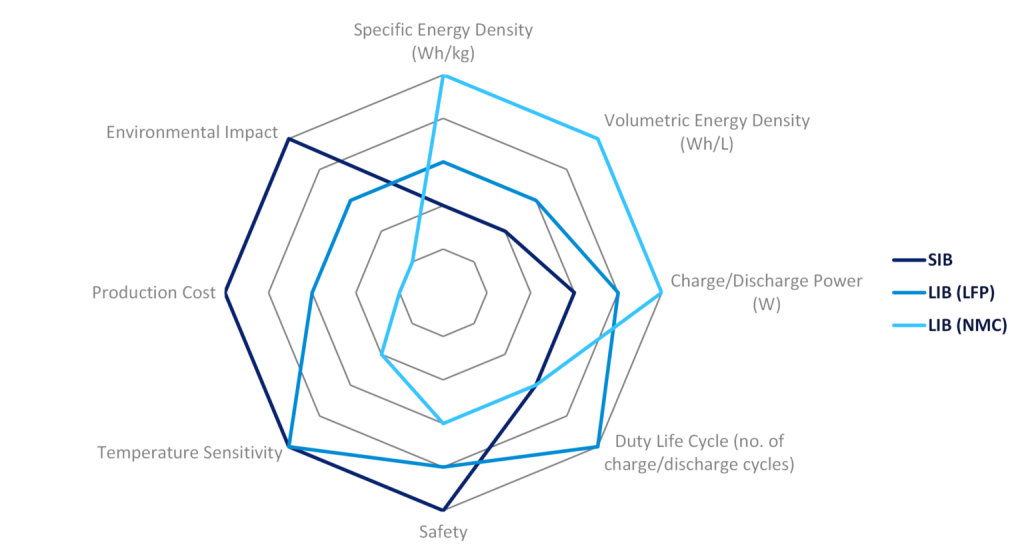

- The primary challenge faced by SIBs is their lower energy density compared to LIBs. Sodium ions are larger and heavier than lithium ions, resulting in reduced on-board energy storage capacity. This limitation affects the driving range and overall performance of electric vehicles, making SIBs less suitable for certain applications that require high power and/or long endurance.

- SIBs have demonstrated a shorter cycle life compared to LIBs. Repeated charging and discharging can cause structural degradation of the sodium-ion electrode, resulting in diminished performance over time.

- The development of SIB technology is still at an early stage compared to LIBs. As a result, SIBs currently face limited commercial availability. The lack of an established supply chain and manufacturing infrastructure may hinder the widespread adoption of SIBs over LIBs.

- SIBs typically exhibit slower charging rates compared to LIBs. Sodium ions have slower diffusion kinetics within the electrode materials, resulting in longer charging times. This drawback may impede the widespread acceptance of SIBs in fast-charging scenarios, where quick and convenient ‘refuelling’ is crucial.

While SIBs may not match the energy density of LIBs (yet), recent figures released from larger cell manufacturers working on SIBs show promising results which are almost competitive with Lithium Iron Phosphate (LFP) cells in terms of energy/volumetric densities while at a lower price point, opening up possibilities within the budget and small vehicles segments.

However, we remain cautious about forecasting the global adoption of SIBs until we see at least some field-tested example vehicles. A comparatively (versus LFP) performing, but cheaper, cell with good life cyclability does sound a bit too good to be true at the moment.

Oliver Petschenyk, Automotive Powertrain Analyst, GlobalData

This article was first published on GlobalData’s dedicated research platform, the Automotive Intelligence Center