As the automotive sector continues its steady transition towards electrification, the success of manufacturers and the new vehicle models they design will become increasingly dependent on how successfully the electric vehicles (EV) battery and body in white (BIW) engineering teams work together.

With EVs expected to account for nearly one third of all car sales across the world by 2030, and a number of countries already well on their way to becoming half electric, competition will intensify and therefore any engineering innovation or operational efficiency that can be developed will be vital.

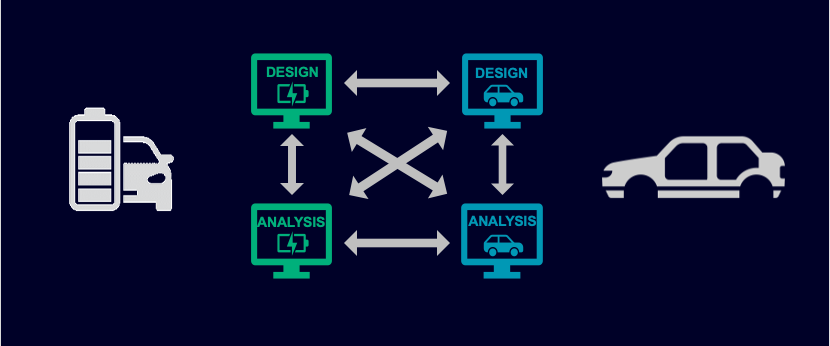

Right from the initial stages of setting out the parameters of the battery pack and the desired operational performance of the vehicle, through to ensuring that it meets all the intensive safety requirements, both sides, battery system and BIW teams, must share information, seek feedback, and work together throughout in order to achieve success.

There are many steps in the design process where design decisions are made to protect the batteries in a crash or to maintain the safety and comfort of the passengers. These decisions will impact design of the battery pack, the BIW structure as well as all the supporting electronics, software, and thermal control systems.

In order to ensure that decisions such as this account for the many complex – and often competing – objectives, both design and engineering teams must take a data and digitally-based approach throughout the product lifecycle.

By putting digitalization at the foundation of the design process, all of the data and the different methodologies that must be drawn upon, are accessible in real time to facilitate collaboration and rapid design decision making. This means that the battery pack and BIW teams are able to constantly update each other and collaborate throughout the design process. This approach also enables EV manufacturers to better manage each stage of the design process while allowing innovation to flourish.

A key advantage of the method is the way in which key EV design factors such as battery thermal management, the vehicle structure, and the overall aesthetic of the finished model can be co-developed on the common platform provided by the latest digital engineering software packages. In addition to ensuring success in the overall design, this also enables key targets such as safety, range and charging time, to be met.

Driving towards a greener future for the automotive sector

As the automotive sector continues its transition to EVs – with an increasing number of major manufacturers targeting to become fully electric by 2030 – the increased adoption of digitally-led engineering processes will enable new ways of working that put collaboration at the heart of the sector.

By embedding an underlying foundation that confronts the communication challenges by digitalizing processes, data flows and methodologies, the engineers, designers and product managers can use this foundation to build a common vocabulary to enable the quick exchange of ideas.

This means that improved skill sets for collaborative will need to be developed between engineering teams that did not typically collaborate in the past. However, having all the electrical, software and mechanical engineers on the same page improves collaboration. The outcome? Designing a safe, comfortable vehicle delivering performance at a good price point.

Deepening the links between BIW and battery teams, not just within individual companies, as already stated, but across the supply chain – will enable even greater levels of innovation and knowledge sharing. Furthermore, those who fail to take such approaches, will be at risk of falling behind.

Whether mandated by those at the top or organically driven by the specific teams involved, this more collaborative manufacturing approach, will pay dividends across the board. From identifying potential flaws in a timely manner or rapidly trialing new concepts in a digital environment, companies will capitalize on the benefits.

Ultimately, the success of these new ways of working will remain largely in the background, but its legacy will be seen on the roads across the world in the form of new electric vehicles that are safe, aesthetically pleasing, comfortable, and critically, enable the automotive sector to drastically reduce its environmental footprint.