With fully electric Neue Klasse (New Class) production edging closer, BMW Group has updated details of how it is expanding its production network for a bew generation of high-voltage batteries significantly.

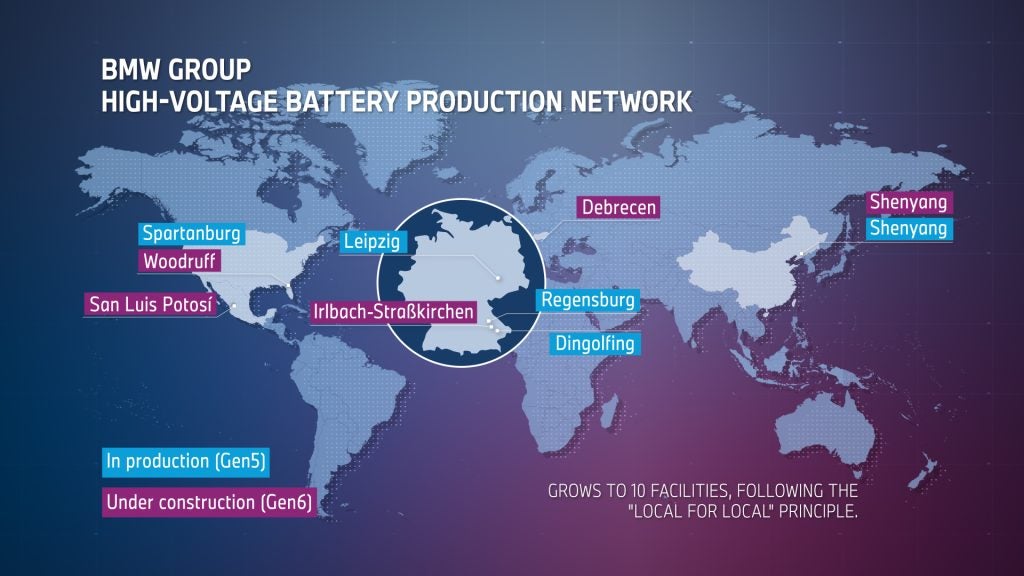

“We are setting up five facilities on three continents to produce our sixth generation HV batteries,” said production chief Milan Nedeljkovic in a statement.

The principle of “local for local” would apply.

"Close connection of battery production with vehicle production is part of our strategy," said battery production head Markus Fallboehmer.

The Neue Klasse will be the first to incorporate the new cylindrical cells which have "vastly" improved energy density, charging times and range. They would be assembled in new factories located as closely as possible to vehicle plants. Facilities are under construction in Irlbach-Strasskirchen (Lower Bavaria), Debrecen (Hungary), Woodruff (near Plant Spartanburg in the US), Shenyang (China) and San Luis Potosí, Mexico.

The “local for local” approach would allow production to continue even when unexpected political or economic events occur while short distances between battery and vehicle plants would reduce the carbon footprint of car production. The group is also upgrading existing sites and securing jobs.

The first Neue Klasse vehicles will be produced at the group’s new plant in Debrecen, starting in 2025, when battery and vehicle manufacturing launch in parallel.

A training centre opened in autumn 2023 and the communications centre was in use from last February while production workers are preparing for their new jobs at various locations across the group production network. That should ensure a smooth start to pre-series production and a successful series launch in the second half of 2025.

From 2026 Neue Klasse vehicles will also be made by the BMW Brilliance Automotive (BBA) JV in Shenyang, China and batteries will be made locally. The production hall was completed in November 2023 and installation of plant and machinery has been under way since last March. The first pre-series batteries will roll off the line at the end of this year. BMW has also set up its largest R&D network outside Germany, with facilities in Beijing, Shanghai, Shenyang and Nanjing.

At San Luis Potosí in Mexico, additional production capacity is being established for series production of the Neue Klasse to start in 2027. Construction of the new battery plant started in May 2024 and will comprise more than 80,000 square metres of production space when completed.

The body shop is set to grow to more than 90,000 square metres in total while vehicle assembly and logistics spaces will expand 10,000 square metres. The group claimed to be the first premium OEM to manufacture fully electric cars and high voltage batteries in Mexico.

In South Carolina. the Woodruff plant will cover about 93 hectares and consist of a technology building, ancillary structures, an energy centre, a staff restaurant and a fire department. It will create 300 new jobs. When construction ends in 2026, Woodruff will assemble batteries for EVs made in nearby Spartanburg. Ground breaking for the first building – the training centre – was in June 2023.

The group is also going to manufacture batteries in Irlbach-Strasskirchen, Lower Bavaria. The new factory will supply German car plants.

Permits were granted last April and the first of 1,000 concrete pillars for the production hall went up in late June.

Prototype cells are already being made at the Cell Manufacturing Competence Centre (CMCC) in Parsdorf, east of Munich built to complement the Battery Cell Competence Centre (BCCC) in the north of the city where development work is carried out.

CMCC scales up the best product for series production.

The BMW Group operates further pre-series plants and pilot lines in Munich and the nearby towns of Parsdorf and Hallbergmoos.