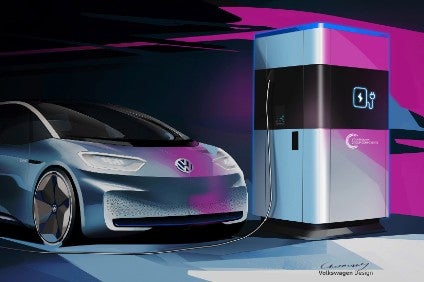

Volkswagen Group Components will start production of a flexible fast charging station in 2020.

This station, a powerbank, can charge up to four vehicles at the same time and also be used for the interim storage of eco-power. The station is to be produced at the Hanover components plant, where heat exchanger production, forming part of the engine business area, will be replaced gradullly by the new e-mobility business.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

Thomas Schmall, CEO, said: "The development of charging infrastructure will be a key factor in the success of e-mobility. The flexible fast charging station developed by Group Components can make a key contribution in this area. This is confirmed by the considerable interest shown by potential partners. The charging station is an element in the end-to-end responsibility of Group Components for the high-voltage battery – from the development of cell production competences through to recycling."

From 2020 onwards, flexible charging station production will gradually replace heat exchanger production, forming part of the engine and foundry business area. The transition to e-mobility will allow the plant to accomplish the urgently needed transformation and will contribute to safeguarding employment and sustainably strengthening the financial situation of the Hanover components plant. In addition, the changeover will ensure that optimum use is made of the skills of employees at the plant. For example, a heat exchanger developer will be able to deploy his know-how in future for the development of battery cooling systems or the optimiSation of thermal management.

Developers and planners have already been involved in piloting the concept for the flexible fast charging station since 2018. The pilot project is to start in the summer of 2019 together with the city of Wolfsburg.

Forecasts indicate that considerable demand for flexible fast charging stations is to be expected in connection with the ramp-up of e-mobility over the next few years.

the charging station is based on the battery package of the Volkswagen Group's Modular Electric Toolkit (MEB) and is designed to use its cell modules. Later, the charging station will provide a second life for batteries from electric vehicles.

VW's Brunswick plant develops and produces battery systems for the Group's electric vehicles. Battery cells are made at Salzgitter and will be joined by rotor and stator production for electric motors from mid-2019. Kassel produces electric motors for full electric vehicles. Hanoveris to focus on charging infrastructure.