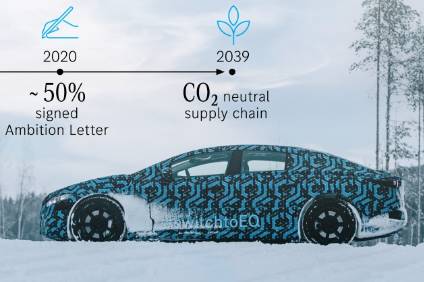

As part of a sustainability drive and campaign, Mercedes-Benz says it will work with suppliers to achieve carbon neutrality in its passenger car production supply chain by 2039.

It says the supplier network is a key element for achieving the climate goals of Mercedes-Benz due to the higher energy demand in the production of fully electric vehicles.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

The transformation to electric mobility in particular increases the energy demand in the supply chain. Compared to a conventional combustion engine, the production of an all-electric vehicle is twice as CO2-intensive, mainly because of the lithium-ion batteries. Mercedes says the entire life cycle of the vehicle needs to be considered. Electric vehicles can make up for a large part of the initially higher CO2 emissions from the upstream value chain due to their emission-free driving.

Mercedes-Benz will work with its global supplier network to reduce CO2 emissions in the production phase.

Markus Schäfer, Member of the Board of Management of Daimler AG and Mercedes-Benz AG; responsible for Daimler Group Research and Mercedes-Benz Cars COO said: “With the electric EQS luxury sedan, which is already in the starting blocks for next year, we have already achieved important milestones in close cooperation with our partners – for example by purchasing CO2 neutrally produced battery cells. We are consequently pursuing this path: When awarding contracts for our subsequent electric vehicle platform – Mercedes-Benz Modular Architecture (MMA) for compact and medium-sized cars- we are already applying CO2 as a key criterion for the first time consistently.”

Almost half of Mercedes cars’ approximately 2000 suppliers have signed an ‘Ambition Letter of Intent’ and are committed to supplying the company with only CO2 neutral parts in the future.

Key criterion for supplier selection

Gunnar Güthenke, Head of Procurement and Supplier Quality, Mercedes-Benz Cars, said there will be an additional focus on particularly CO2-intensive components and materials such as battery cells. “We are also in the process of setting up a tracking system that will enable us to see how CO2 emissions are reduced over time,” he said. The company is in close dialogue with all other suppliers to jointly develop strategies for CO2 reduction.

A supplier declining to sign the Ambition letter will not be taken into account for new supply contracts, Mercedes said.

Focus on CO2-intensive components and materials

Mercedes-Benz will additionally focus on materials and components that are particularly CO2 intensive in manufacturing and processing until 2039. Focus components include battery cells, steel, and aluminium. These components account for about 80 percent of the CO2 emissions in the supply chain of a fully electric vehicle. Mercedes-Benz has already agreed on clear objectives with two strategic partners for battery cells: CATL (Contemporary Amperex Technology Co., Limited) and Farasis Energy have committed to supply battery cells that are produced using electricity from renewable sources such as hydropower, wind, and solar energy. This reduces the CO2 footprint of an entire battery by more than 30 percent. The rest of the supply chain will be included as a next step.

The company’s goal is to consistently reduce the use of primary raw materials for electric drives by 2030 and gradually increase the share of secondary and renewable materials in vehicles. Mercedes-Benz is working with its partners to gradually increase the share of secondary material in the focus materials.

Mercedes-Benz plants as role model

Mercedes-Benz AG’s own plants, including the global battery production network, will produce on a CO2 neutral basis worldwide from 2022. This will make them role models for the supplier network. In line with the procedure in Mercedes-Benz’s own plants, suppliers are required to avoid and reduce emissions as a fundamental principle. Only then can compensation via high-value projects be considered. The areas of approach for climate-neutral production are diverse, and range from reducing consumption to purchasing energy from renewable energy sources.

Ambition 2039: Climate-neutrality along the entire value creation chain

With its new strategy, Mercedes-Benz says sustainability extends as a guiding principle across all strategic fields. The goal is a fully networked and completely CO2 neutral vehicle fleet. ‘Ambition 2039’ gives the direction for this along the entire value creation. The company aims to have plug-in hybrids or all-electric vehicles to make up more than 50% of its car sales by 2030. Major milestones include CO2 worldwide neutral production in all of Mercedes-Benz AG’s own plants from 2022, involvement in shaping the charging infrastructure and agreeing to specific CO2 measures with suppliers.

See also: Blockchain technology on the rise for supply chain transparency