Mahle has developed a heat pump based device for heating electric vehicle cabins it calls Integrated Thermal System, or ITS, and claims an increase in winter cruising range of up to 20%.

“In addition to significantly reducing battery power consumption, it is easy to control and can be readily adapted to future vehicle architectures,” the supplier said.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

Most current electric vehicles rely on direct resistive heating using electricity to heat the cabin and traction battery in winter. This extra load on the drive train battery in cold temperatures can reduce the cruising range of a fully charged vehicle by up to half. Summer cruising range is shortened by the additional energy required for cooling the drive train battery and the cabin.

In field tests with an unnamed “compact electric car” Mahle said it showed ITS reduces the loss of cruising range “substantially”, especially in cold temperatures. The original vehicle used, equipped with conventional electric heating, started with a cruising range of 100km. Equipped with the ITS, cruising range increased to 116km.

“We can improve cruising range by between 7% and 20%, depending on the design, which drastically reduces the loss of cruising range in winter in particular,” said Laurent Art, the supplier’s head of advanced engineering thermal management.

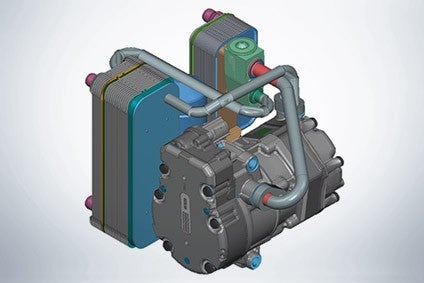

The ITS combines various thermal components into one system that functions in several modes. Central to its architecture is a semi-hermetic refrigerant circuit, comprising a chiller, a coolant-cooled condenser (i-condenser), a thermal expansion valve and an electric drive compressor. The i-condenser and chiller have the same function as the condenser and evaporator in a conventional refrigerant circuit.

However, instead of exchanging heat with air, the refrigerant exchanges heat with the coolant, thus generating hot and cold coolant flows.

The ITS uses R1234yf as a refrigerant and the conventional vehicle coolant as the medium for heat transport between the cooling circuit and the various heat sources and sinks in the vehicle.

In addition to the low cost and environmental benefits, the ITS presents design flexibility and adaptability as added advantages.

Tests for control optimisation and other purposes are currently being run in a climatic wind tunnel with the ITS installed in the vehicle.

Together with unnamed “American OEMs”, the supplier is working on implementing additional performance and cost optimisation.