Lanxess has unveiled a new design for electric vehicle charging inlets.

The boom in electric vehicles is causing a sharp rise in demand for plastics destined for charging infrastructure.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

Lanxess says it is “convinced” the area offers a wealth of opportunities to use its Durethan polyamides and Pocan polyesters.

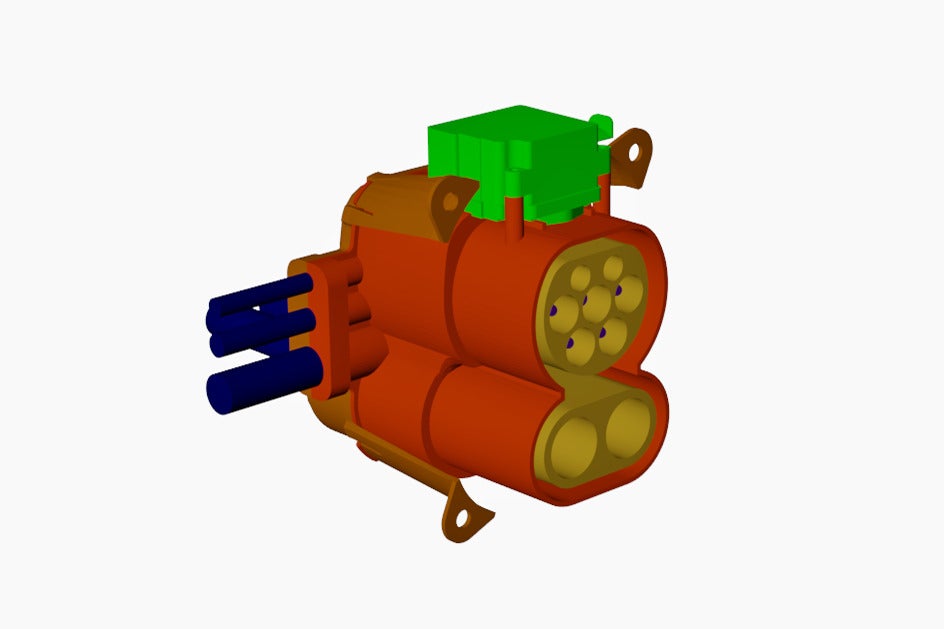

The possibilities gained by these thermoplastic compounds are demonstrated in a new design concept from Lanxess for charging inlets. These are installed in battery electric vehicles and accommodate the charging coupler of the external charging station.

“Our approach is aimed at using a modular configuration to get the right material in the right place to meet the complex requirements applicable to the various components with the utmost precision,” said application developer at the High-Performance Materials (HPM) business unit, Gregor Jaschkewitz, who devised the design.

“At the same time, a high level of functional integration is intended to make it as easy as possible to assemble the entire unit, which means screwless assembly and minimal components in order to keep costs low.”

The design is the product of discussions with manufacturers of charging systems and incorporates the experience Lanxess has already accumulated in charging infrastructure development projects.

“This means it also satisfies a desire expressed by many manufacturers to have the ability to be as flexible as possible when it comes to charging inlet sealing,” added Jaschkewitz. O-rings, sealing cords or family seals can be used, for example, as can be employed lip seals, manufactured in a two-component injection moulding process.

Integrated thermal management:

The key elements of the charging inlet design are the front and rear housings, a socket for the connector from the charging station and an actuator. The latter locks the connector in place to prevent it from being accidentally or deliberately pulled out during the charging process.

The pin holder is another essential element. It holds the metallic connector pins in place, as well as a printed circuit board (PCB) with cables for charging with direct or alternating current, among others. Particular attention was paid to the design of the pin holder. It positions the cables such that the heat produced during charging is dissipated not only through them but also via the other cables not in use.

“This means the pin holder supports the thermal management and thus makes fast charging at high currents easier,” noted Jaschkewitz.

Once the cables and contact pins have been placed in the holder and the PCB has been clipped in, all the charging inlet components are put together with the aid of snap fits. The cables are fastened in place under minimum strain so they cannot become detached in the housing. “The ability to join the components without the need for screws simplifies the assembly process and associated logistics, which, in turn, cuts manufacturing costs,” said Jaschkewitz.

High material requirements fulfilled:

Plastics for charging inlets are required to comply with the IEC 62196-1 standard and deliver high electrical insulation resistance as well as dielectric strength and tracking resistance. Good fire-retardant properties are also essential.

Parts that come into direct contact with live components must pass a glow-wire end product test (GWEPT) in accordance with IEC 60695-2-11 at a glow-wire ignition temperature of 850 °C. After being stored at 80 °C for seven days, the plastic parts must not exhibit any surface changes – such as cracks – caused by ageing.

High-grade mechanical properties (for example, good toughness) are also required to ensure the charging inlet is not susceptible to bumps or vandalism. “Our material solutions include compounds that are ideally suited to this range of requirements,” added HPM Application developer, Sarah Luers.

“In some cases, versions developed specifically for electric vehicles are also available. This includes, for example, highly weather- and UV-resistant products for housings, as well as materials exhibiting low shrinkage and warpage for components that need to be particularly dimensionally stable.”

Thermally conductive polyamide 6 compounds with good mechanical properties are intended for use in the pin holder, which is subject to heavy thermal loads. This also includes product types that pass the UL 94 flammability test prescribed by the US Underwriters Laboratories testing institute with a V-0 rating.

Support in component design:

Lanxess assists charging system manufacturers with a range of services through its HiAnt service brand. On behalf of its project partners, for example, it calculates and simulates how component geometry and material will affect the generation of heat in the component. Other services include performing flammability testing in compliance with standards and conducting mechanical evaluation such as ball drop tests.

Design for charging plug also in development:

Lanxess is currently considering applying the new design to further assemblies of the charging infrastructure – such as the charging plug.

The design and materials experience built up during work on the vehicle charging inlets can be deployed to a large extent here as requirements are very similar.