VW Group-owned Audi says that improvement suggestions from its employees led to cost savings of approximately EUR108.6m in 2017.

It said that it implemented around 15,000 improvement suggestions from its employees last year and that the resultant cost savings were up 23.4% on the previous year.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

Audi said it places importance on ‘quick and lean processes in its ideas management’. Experts from the relevant departments examine the employees’ suggestions at headquarters and decided directly on implementation.

An online tool informs the employees about how the process is progressing and ensures maximum transparency. An internal ideas agency accompanies and advises the employees. The Audi employees receive financial rewards from the company for suggestions that are implemented, the amount of which depends on the savings achieved.

“We always encourage our employees to look very closely at their own working area and to question the status quo,” said Joachim Kraege, Head of Organisation and Consulting at Audi, “because the creativity and inventiveness of everyone at Audi are crucial success factors for us.”

Klaus Mittermaier, Chairman of the Group Works Council at Audi said: “It is our workforce that makes the long-term success of our brand possible. The Audi Ideas Program shows that very clearly. So it’s very important to us as members of the Works Council that our colleagues personally profit from their improvement suggestions.”

Audi said that it is often ‘apparently small, unspectacular ideas’ from one’s own working area that improve processes, avoid waste or make work easier. For example, two auto-mechatronics apprentices had the idea of marking torque-wrench sockets green and red. The colour system eases the fitting of the sockets, prevents the wrong use of the tool and therefore saves time.

Thanks to the idea of two employees in engine development, Audi saves approximately EUR100,000 each year. The two maintenance workers noticed that the ventilation systems in their buildings were operating day and night. Their suggestion: reducing the fans’ speed when no-one is present. The ventilation systems are switched on during the week only from 6 a.m. until 10 p.m.

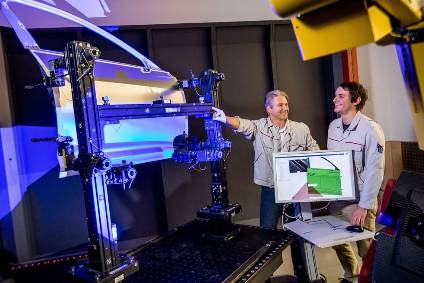

In the area of quality assurance, three employees improved the method of measuring car doors: They reduced the time required to adjust the measuring instruments from 34 to just 18 minutes for each door. As a result, they and their colleagues save 200 working hours each year, in which they can now concentrate on other tasks.

Audi said there has been an employee suggestion scheme at Audi for 50 years, and the Ideas Program has existed in its current form since 1994. The Audi Group has established ideas programs also at its other plants in Europe. In Gyor and Brussels, the company implemented more than 10,100 employee suggestions in 2017 and saved approximately EUR33m.