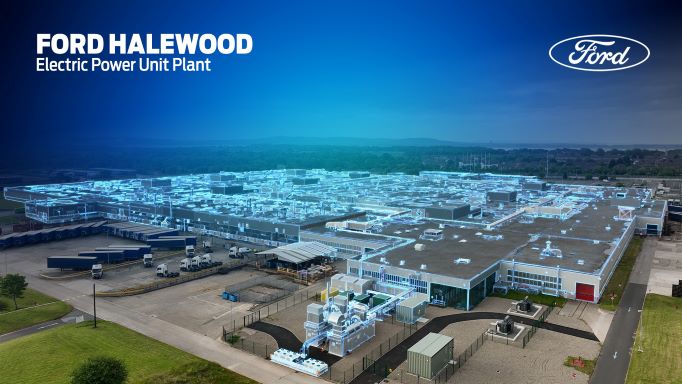

Ford said it had invested a further GBP125 million in its Halewood Plant, on Merseyside – increasing capacity by 70% – plus GBP24m in the supporting E:PRiME product development centre.

Today’s announcement takes total investment in turning Halewood into an EV component plant to almost GBP380m.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

The latest investment – which includes government support from UK Export Finance, through their Export Development Guarantee – will help safeguard 500 jobs.

Kieran Cahill, Ford’s European industrial operations vice-president, said: “Ford is a global American brand, woven into the fabric of Europe for more than 100 years and a major employer at Halewood for almost 60 years.

“Our vision in Europe is to build a thriving business, by extending leadership in commercial vehicles and through the electrification of our car range. Halewood is playing a critical part as our first in-house investment in EV component manufacturing in Europe.”

Last year’s news that the plant, which currently produces transmissions for internal combustion engine vehicles, had won assembly of electric vehicles power units brought an initial backing of GBP230m to deliver 250,000 units a year from 2024. This was supported by BEIS’ Automotive Transformation Fund, which aims to electrify Britain’s automotive supply chain and protect its competitiveness in the global market.

The GBP24m E:PRiME centre, at Ford’s Dunton product development HQ, is building prototypes of the electric power unit and training Halewood employees in machining and assembly, assisted by the Advanced Propulsion Centre.

Tim Slatter, chairman of Ford UK, said: “This is an all-important next step towards having nine EVs on sale within two years. Our UK workforce is playing a major role in our all-electric future, demonstrated by Halewood’s switch to a new zero emission powertrain, and E:PRiME’s innovation at Dunton in finalising the production processes.”

The new power unit capacity means 70% of the 600,000 EVs, which Ford will sell in Europe a year by 2026, will be powered by Halewood produced technology. Ford’s EV push in Europe supports the acceleration of the company’s global plan for two million annual production of EVs in the same 2026 time frame.

UK built EV power units will eventually go into the Puma, E-Transit Custom, E-Tourneo Custom, Transit Courier, Tourneo Courier and planned future products.

Halewood will deliver to vehicles assembly lines at Ford Otosan plants in Romania and Turkey, making up a significant share of annual export value from the Merseyside plant, as well as Dagenham – currently worth GBP2.1bn annually.

Apprentices and engineers from the electric power unit development project have been part based at E:PRiME in Essex, test building the power unit and implementing new skills and knowledge at Halewood.

Halewood’s selection marked Ford’s first in-house investment in all electric vehicle component manufacturing in Europe.

Halewood’s new electric power unit operation is targeting carbon neutral energy supply for production start in 2024. Electricity and gas are already from renewable sources and the installation of solar panels will generate up to 1,782 MWh. Other Halewood projects contributing to total carbon neutrality for Ford in Europe by 2035 include electric locomotives (used to shunt heavy loads) replacing diesel locos and EV charge points for employees.