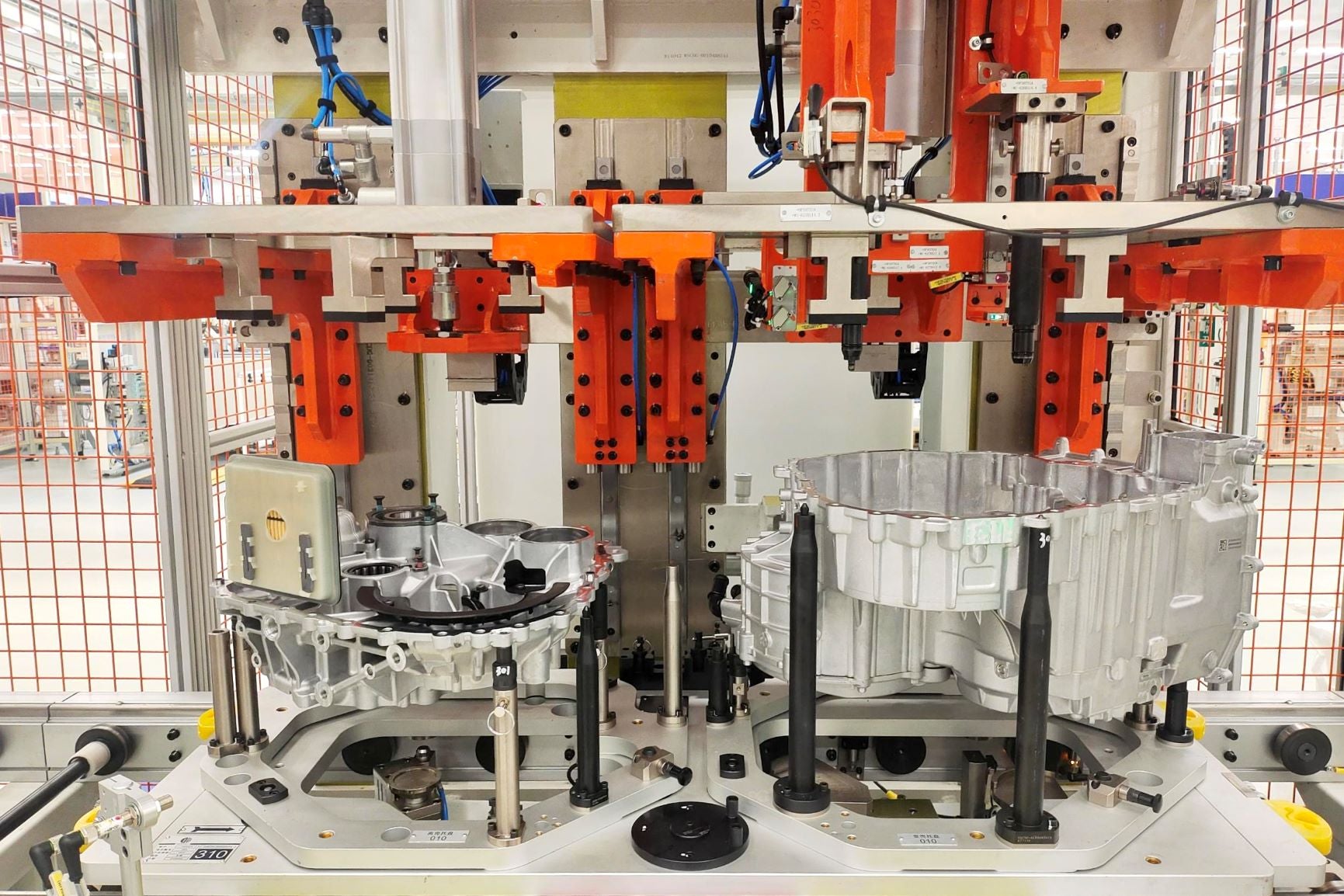

Comau has designed and deployed a high-volume, automated assembly line for HYCET, a wholly-owned subsidiary of Great Wall Motor and a manufacturer of DHT (Dedicated Hybrid Transmission) technology.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

The L.E.M.O.N. hybrid DHT is described as a next-generation transmission system that allows for the simultaneous use of gasoline engines and electric motors, enabling efficient power sharing between them.

To meet the customer’s large-scale manufacturing targets, Comau’s end-to-end solution features a total of 12 robots across 6 lines to deliver an annual production capacity of 150,000 units per line with a cycle time of less than 2 minutes, it says.

Within the scope of the project, Comau has wholly developed the necessary components, including e-motor assembly lines, gear and shaft assembly lines, main assembly lines, and the assembly test lines. The system also includes critical processes that grant full-process assembly from individual components to fully functional units.

Furthermore, the high-speed production solution also ensures better adaptability and efficiency while lowering the production costs for future DHT product upgrades. It is claimed the Comau-designed production line can be easily customized to meet different market needs.

Comau has also used a process-integrated overall station design to guarantee stability and quality across the entire production line with an equipment availability rate of 90%. A MES (Manufacturing Execution System) allows HYCET to optimize the management and scheduling of the line. Finally, key process parameters, such as force and displacement, are constantly monitored to ensure quality control throughout the entire production process and support subsequent data traceability.

“HYCET’s DHT technology represents cutting-edge innovation in the hybrid vehicle sector and delivers outstanding performance for Great Wall Motor’s DHT system. As our technology partner, Comau’s design and engineering capabilities confirm their exceptional position in this field,” said Wu Hongchao, Vice President of HYCET Technology Co., Ltd. “Throughout the project implementation phase, Comau adhered to the project schedule despite the recurring impacts of the pandemic, and ensured consistent manufacturing quality. This stability is critical for our production goals, allowing us to meet market demands and maintain optimal manufacturing efficiency.”