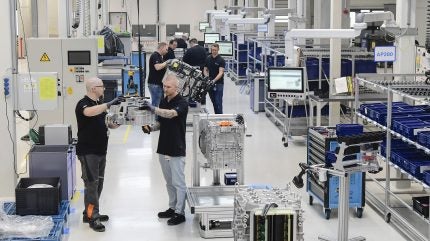

Cellcentric, the joint venture between Daimler Truck and the Volvo Group, has begun pilot production for fuel cell systems at its Esslingen-Pliensauvorstadt site in Germany.

The company is working towards supplying fuel cells on a large scale by the end of the decade when fuel cell powered, long haul, heavy duty trucks are predicted to become a key technology for sustainable transportation.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

The goal is to develop, produce and distribute fuel cell systems on a large scale in which achieve the best possible total cost of ownership in the highly competitive transportation industry.

Cellcentric also intends to cover the entire fuel cell ecosystem from the product itself to maintenance and recycling at the end of its life cycle.

“Fuel cell technology is a well-proven solution for CO2 neutral, long distance, heavy duty transportation. However, it has not yet been produced on an industrial scale, which is precisely the key to achieving economies of scale, optimising the total cost of ownership (TCO) and putting [us] in a solid competitive position in the long term,” said Lars Johansson, chief commercial officer and chief organisational officer at Cellcentric.

One hundred employees have 10,300 square metres of production, logistics and office/administration space in the property which is part of the Esslingen industrial park greenfield.

In a next step, cellcentric will establish the necessary production processes at the site to prepare for the start of large scale production with a high degree of vertical integration with complete production at one location and a high level of automation.

A comprehensive service package including all maintenance and repair services will ensure that maintenance related downtimes and unforeseen failures or breakdowns are reduced to a minimum, an important criterion in the transport industry for the best possible utilisation of vehicle capacity.

Cellcentric is planning an environmentally friendly return of the fuel cell systems at the end of their life cycle.

This will include the reuse of decommissioned fuel cell systems for other applications with a lower requirement profile, refurbishment, a reconditioning and recycling of fuel cell systems for a longer useful service life, remanufacturing – the total overhaul to refurbish and make the systems as good as new again and the recovery of raw materials and reuse in new fuel cell production through recycling.