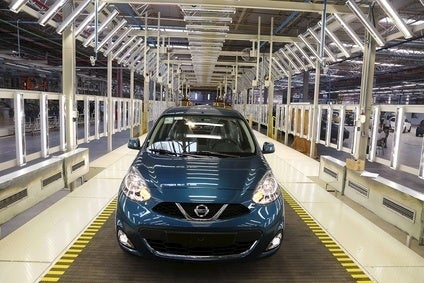

Nissan has officially opened its BRL$2.6bn (US$1.5bn) factory complex in Resende, Rio de Janeiro, Brazil which is one of the largest automotive investments by any manufacturer in the country.

This is part of an effort to achieve 5% market share and to become the top Japanese automotive brand in Brazil.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

The new factory already employs about 1,500 people and is expected to grow to around 2,000. The complex includes all facets of automotive production – from the stamping of sheet metal to vehicle assembly and road course testing for the estimated 200,000 vehicles and 200,000 engines the complex will have the capacity to produce each year.

Resende is producing Platform V vehicles and engines starting with the March [Micra] and the 1.6 16V flexfuel engine.

All employees have undergone special training and more than 300 have trained outside Brazil for three months at plants in Japan, Mexico, the United States and England. The vehicle quality control team underwent six months of special training in Japan and Mexico. In the last year, Nissan has spent more than $4m on technical training for the Resende workers.

Eighty-eight robots carry out tasks that demand more precision or could incur safety or ergonomic risks. In most areas, automatic guided vehicles (AGV) move small carts of parts, eliminating the need for transportation belts with combustion engines or platforms activated by chains, making the operation safer and quieter.

The vehicle painting process follows the modern and sustainable ‘3Wet’ water-based paint system with base and varnish done soon after primer application, making the process shorter and reducing energy consumption. The paint robots use cartridges that reduce the waste of paint and solvents, reducing the emission of volatile organic components (VOCs) and making the operation more environment friendly.

Other green features are natural illumination and ventilation systems, which reduce energy consumption and have low environmental impact. Production processes also reuse water by filtering solids for recycling or proper disposal. The objective is to constantly reduce CO2 emissions and the amount of volatile organic compounds (VOCs) created by production.

Outside the walls of the plant, a green belt will be planted to surround the entire complex, which will help to reducing both emissions and noise. The belt will reflect the region’s natural habitat and occupy an area of more than 12 acres.

Nissan also has committed to investing in the preservation green areas in the region with reforestation in some habitats. The company will create an environmental preserve for the Turfeira Lagoon located next door which is fundamental to maintaining biodiversity and an ecosystem that’s required for the survival of more than 150 species of birds.

The new complex gives Nissan an opportunity to create a much larger presence in Brazil and continue to grow. To accommodate additional growth, infrastructure for a supplier park has been set up adjacent to the complex. The supplier park already has four auto parts suppliers set up in addition to two that operate inside the plant. These suppliers, which have moved to the region to support Nissan, include: Tachi-S, seat producers; Yorozu, suspension supplier; Kinugawa, rubber seal producer; Calsonic Kansei, cockpit components; Mitsui Steel, plates supplier; and Sanoh, brakes and fuels pipes.

Nissan aims to reach a rate of nearly 80% local content in Resende by 2016.

“The Nissan Industrial Complex of Resende is fundamental to achieving our growth objectives in Brazil, which is the fourth largest automotive market in the world and a key part for our development in Latin America. Our goal is to achieve 5 percent market share and to lead Japanese automakers in quality and customer service in Brazil by 2016,” said Nissan chairman and CEO Carlos Ghosn at the opening ceremony.

“Nissan’s expansion of our manufacturing capacity throughout the Americas over the last two years, with new plants opened in the United States (2012), México (2013) and now in Brazil (2014) underscores the untapped opportunities that we foresee throughout the hemisphere and, specifically, in Brazil,” said Jose Luis Valls, chairman of Nissan Latin America.

Nissan began operations in Brazil in 2000.