Audi is claiming its SQ7 electric powered exhaust gas compressor is a world first on a production car. It has also added a 48-volt electrical subsystem and electromechanical active roll stabilisation.

The automaker said a new V8 diesel combining turbocharging with an electrically powered compressor consigns ‘turbo lag’ to history.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

The redesigned ‘BiTDI’ engine that now develops 435 PS and 900 Nm (663.8 lb-ft) of torque. The electrically powered compressor helps 0-62 mph accleration in just 4.8 seconds. Top speed is limited to 155mph and up to 38.2 mpg combined is achievable with CO2 emissions of 194g/km.

The 3,956cc engine also uses two exhaust-gas turbochargers which are activated selectively (sequential charging) since exhaust gas only flows through one turbocharger at low and intermediate load. The second turbine is only activated at higher loads. The electrically powered compressor (EPC) augments the work of the two turbochargers, particularly in the lower engine speed range, providing for extremely responsive off-the-line performance.

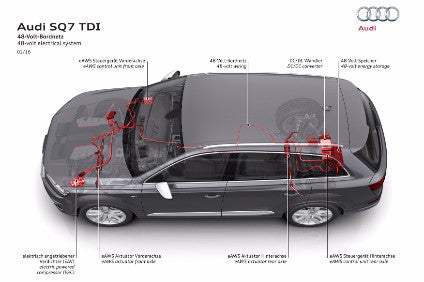

Forced induction concept and electrical system: Electric powered compressor (EPC) and 48-volt subsystem

The electrically powered compressor is a world claimed first in a production vehicle. It operates when starting off and accelerating from low load. It is placed in the air path downstream of the intercooler, close to the engine. Because the EPC does not require any exhaust-gas energy to develop boost, it can be used at any time.

The EPC provides the engine with the boost energy needed for the dynamic delivery of power in less than 250 milliseconds. Driven by a compact electric motor, its compressor wheel spins up to 70,000 revolutions per minute.

Audi has also introduced a new valvelift system with this engine. The inlet and exhaust cam shafts each have two cam contours per valve. On the inlet side, one cam contour supports starting off in conjunction with the EPC, while the other optimises cylinder filling and thus power at high engine speeds. The AVS system on the exhaust side enables activation of the second exhaust-gas turbocharger. The sequential charging system controls the two exhaust-gas turbochargers so that only one turbocharger is used at low engine speeds. The second is activated additionally at higher loads and engine speeds.

The exhaust streams from the two exhaust valves are hermetically separated, with each driving one of the two turbochargers. In the lower engine speed range, one valve per cylinder remains closed, so that the full exhaust stream flows to the active turbocharger. When load and engine speed increase, the AVS opens the second exhaust valves. This directs flow to and activates the second exhaust-gas turbocharger. The engine achieves its maximum output in this biturbo mode.

Power for the EPC, which reaches a maximum of 7kW, is provided by the 48-volt electrical subsystem which also facilitates the electromechanical active roll stabilisation (EAWS). To meet their high power and energy requirements, the electrical subsystem includes its own 48-volt lithium-ion battery mounted beneath the luggage compartment with a nominal energy content of 470 watt-hours and peak output of up to 13 kilowatts. A DC/DC converter connects the 48-volt and 12-volt electrical systems. The required energy is provided by a more powerful and highly efficient generator with an efficiency of over 80% at an output of up to 3 kW. This is a so-called MOSFET generator (Metal Oxide Semiconductor Field Effect Transistor), which reduces electric losses and increases efficiency. MOFSETs replace the diodes used previously. In addition, the 48-volt storage unit supports the 12-volt electrical system when required. This also reduces the load on the 12-volt lead battery.