From Beetle Wings to Airless Tires and Beyond

Tinius Olsen has been supporting the London South Bank University School of Engineering in testing a unique one way hinge developed from the wings of insects.

This new discovery from the wings of a flying beetle sheds light on how a wing changes shape in flight using an unusual bell shaped structure, which is compliant in one direction but almost ten times stiffer in the opposite direction.

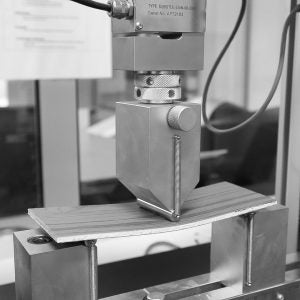

Results have shown that the structure is an effective one-way hinge that achieves functionality using a single material with no extra mass. The use of the insect-inspired hinge in applications, including easily assemblable modular designs, adaptive airless tires, and metamaterials with zero Poisson’s ratio, suggests that the structure can have biomimetic applications over a considerable size range.

“Insect wings present striking examples of automatic shape morphing in both nature and technology, the mechanisms of which are not fully understood,” says London Southbank University School of Engineering lecturer in Mechanical Engineering and Design Hamed Rajabi,

“These Insect wings are deformable airfoils, in which deformations are mostly achieved by complicated interactions between their structural components.”

“Due to the complexity of the wing design and technical challenges associated with testing these delicate wings, little is known about the properties of their components and how they determine wing response to flight forces. This is especially true of an unusual structure from the hind-wing membrane of the beetle Pachnoda Marginata or Sun Beetle.”

“Mechanical ‘hinges’ and associated asymmetric bending and twisting are widespread in insect wings and, whilst operating in flight, these hinges allow the wings to deform automatically and asymmetrically between the upstroke and downstroke. They also control the precise, complex patterns of folding and unfolding in the hind wings.”

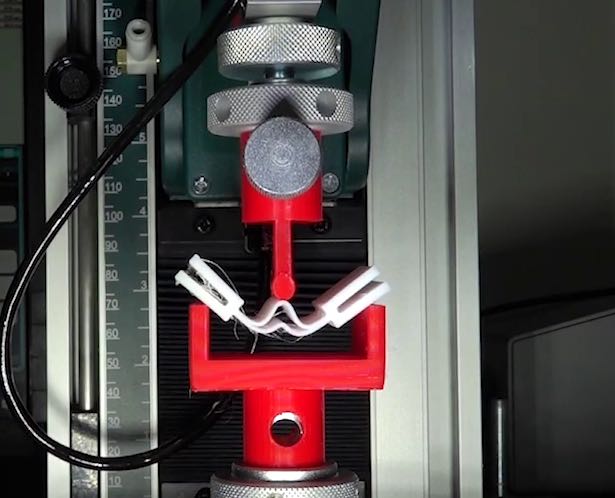

“In this particular instance, the hinge is of a double membrane type, which is dependent on reversible thin-plate buckling. From real-scale computational simulations and up-scaled physical modelling, it was confirmed this double-layer membrane can act as a one way hinge.”

“The structure consists of two distinguishable layers: a bell-shaped upper layer and a nearly straight lower layer. Our computational simulations showed that this is an effective one-way hinge, which is stiff in tension and upward bending but flexible in compression and downward bending,” continued Hamed.

“By systematically varying its design parameters in a computational model, we showed that the properties of the double-layer membrane hinge can be tuned over a wide range. This enabled us to develop a broad design space, which we later used for model selection.”

“We used selected models in three distinct applications, which proved that the double-layer hinge represents a simple yet effective design strategy for controlling the mechanical response of structures using a single material and with no extra mass.”

So what are the potential applications for this discovery?

“The hinge has many potential biomimetic applications. Firstly we created a modular design that could be easily assembled and disassembled followed by a design for an airless tire, which could have numerous applications across a number of sectors.”

“We also created a meta material with zero Poison’s ratio, where we could control the compressive behaviour of the material by using our joints, which again could be applied across a large number of applications,” said Hamed.

“This biological one-way hinge offers biometric inspiration for the design and development of engineering structures that exhibit asymmetric responses to equal forces applied in different directions. This is particularly interesting because the double-layer membrane offers a simple, inexpensive way of making a one-way hinge without increasing the mass.’

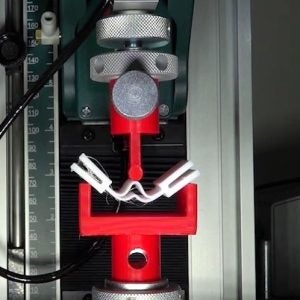

Tinius Olsen supplied a 1ST UTM equipped with a 500N loadcell, which not only performed the required tension and compression testing but could also be used in combination with the custom setups developed by Hamed and his team.

“The support from Tinius Olson with this project was incredible. The comprehensive help and support provided with the selection of the correct testing machine, load cell, and accessories was invaluable. Their support staff were always available to answer any questions we may have and the full day instruction on the 1ST and Horizon software was especially helpful, as well as developing all the testing protocols we required. We certainly wouldn’t have achieved what we have with this study without the company’s input,” said Hamed.

For the full article, please visit the Tinius Olsen website.