Cincinnati State Technical College, a Tinius Olsen Success Story

Tinius Olsen has helped one of the leading Technical Colleges in America, the Cincinnati State Technical and Community College, to upgrade and further develop its materials testing laboratory.

This is the culmination of a partnership between the two organisations that goes back to the establishment of the College in 1969, as Mechanical Engineering Technology and Welding Technology department professor and programme chair Mike DeVore explains:

“I started teaching at Cincinnati State 29 years ago and at that time we had a very old Tinius Olsen tensile test machine that still worked extremely well on a day to day basis.”

“Our testing lab had been in operation since almost the establishment of the school so we decided to update our lab in 1993 and, due to the reliability and generally good history that we had with the old machine, I decided to purchase another from Tinius Olsen.”

“I visited the factory in Pennsylvania and was very impressed with the quality of work and professionalism of the employees at the company, so we purchased our second Tinius Olsen machine, a 60L Super L Tensile Tester. Again we enjoyed great service with the machine until the controls unfortunately failed last year.”

“Fortunately, we had obtained funding to upgrade our materials test lab with all new equipment and it was a relatively easy decision to once again look to Tinius Olsen, thanks in the main to the great experience we have had with the company over the years. It was also important to me to try to purchase American made equipment, whenever possible.”

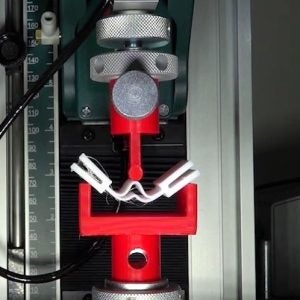

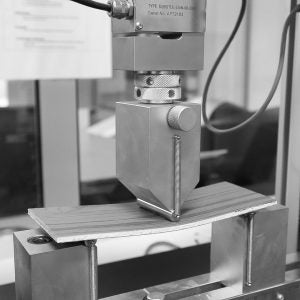

The machines installed at the colleges’ testing lab are a 10,000 In/lb Bench Top Torsion Tester, a Model IT406 Pendulum Impact tester, four Rockwell, and one Brinnel Hardness Testing machines, as well as retro-fitting the 60L Super L. This has resulted in a substantial investment by the college into their state of the art testing laboratory, which should see at least another 30 years problem free use.

“The new equipment is used in several courses within our Mechanical Engineering Technology, Welding Technology, and Civil Engineering Technology programs. The primary use is in our MET 140 Engineering Materials course where our students spend the semester doing destructive testing.”

“Between the three programs we have over 500 hundred students, all of which will use this lab at some point in their curriculum. The tests we currently perform within the lab include tensile, bend, hardness, torsion and impact testing as well as heat treating.”

Cincinnati State Technical and Community College, which is celebrating its 50th anniversary this year, provides student-focused, accessible, high-quality technical and general education, academic transfer, experiential and cooperative education and workforce development.

The college offers more than 130 associate degree and certificate programs through its four academic divisions and the Workforce Development Centre.

“We have a long history with Tinius Olsen. We have used their material testing equipment for nearly 50 years here at Cincinnati State and intend to keep the relationship intact for years to come. They are a great American company and we are proud to use their equipment to educate our students,” continued Mr DeVore.

“Through the use of our Tinius Olsen equipment we are able to prepare our students to go out into industry with a thorough knowledge of material testing. Tinius Olsen test equipment is used by many of our employers and they appreciate the fact that our students are learning to use industry standard equipment.”