BMW started production of the fifth generation Mini Cooper hatchback in Oxford, England, on Monday.

The milestone car was a three door hatchback.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

As usual, all three BMW Group factories are involved with Swindon producing body pressings and subassemblies while three and four cylinder petrol engines come from the Hams Hall facility in North Warwickshire. Oxford takes care of body shell production, paint and final assembly.

Oxford, once a Pressed Steel body plant like Swindon, has now built 4.4m BMW Minis since 2001 including 150,000 EVs assembled between 2019 and 2023.

Two new EV models will be made from 2026.

First customer deliveries will be in spring 2024.

Production of the Countryman started in Germany late last year and electric variants went on line earlier this month.

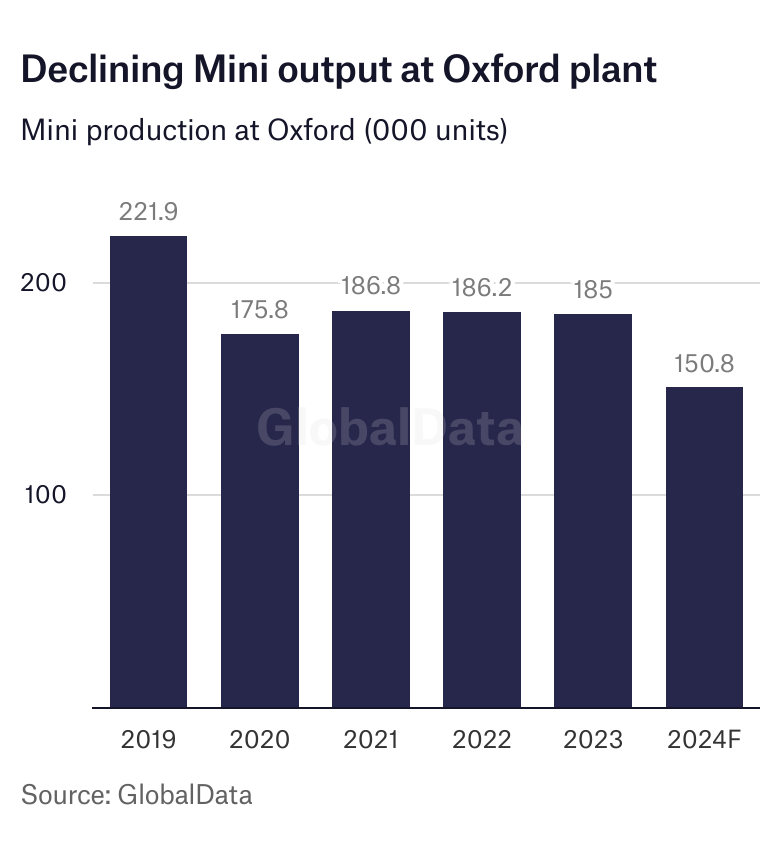

Mini’s Oxford plant has seen a decline to overall output as BMW has reconfigured its Mini global production base for new models and the transition to electric.

However, the Oxford plant will start making the first of two EVs in 2026. The Cooper line of cars is to be joined by a second electric vehicle, that being the yet to be revealed Aceman. Named after a concept from 2022, this larger car is expected to be revealed in April (2024).

Positioned above the new smallest models, the Aceman can be considered a successor for the Clubman.