The Volkswagen Group says it has reached a milestone in producing five million electric drive units worldwide. The collective achievement by the Győr, Kassel, Tianjin and Zuffenhausen plants underscores the VW Group-wide technology and production alliance as well as the systematic scale-up of e-mobility across brands and regions.

The company says the Volkswagen Group Components’ competence network is a key enabler – the Kassel plant alone increased production of electric drives in 2025 by around 24% year-on-year to over 850,000 units.

Thomas Schmall, Volkswagen Group Board of Management member for Technology, said: “Producing five million electric drives is a milestone that underscores Volkswagen’s lead in both the ICE and the BEV segments. Our global development and production network allows us to master all aspects of the electric drivetrain, accelerate innovation and ensure outstanding quality. In developing our first pulse inverter in-house, we are building up additional expertise and taking the “brain” that controls the electric drive unit into our own hands. This not only safeguards high performance for our customers but also reinforces the technological sovereignty of the Volkswagen Group.”

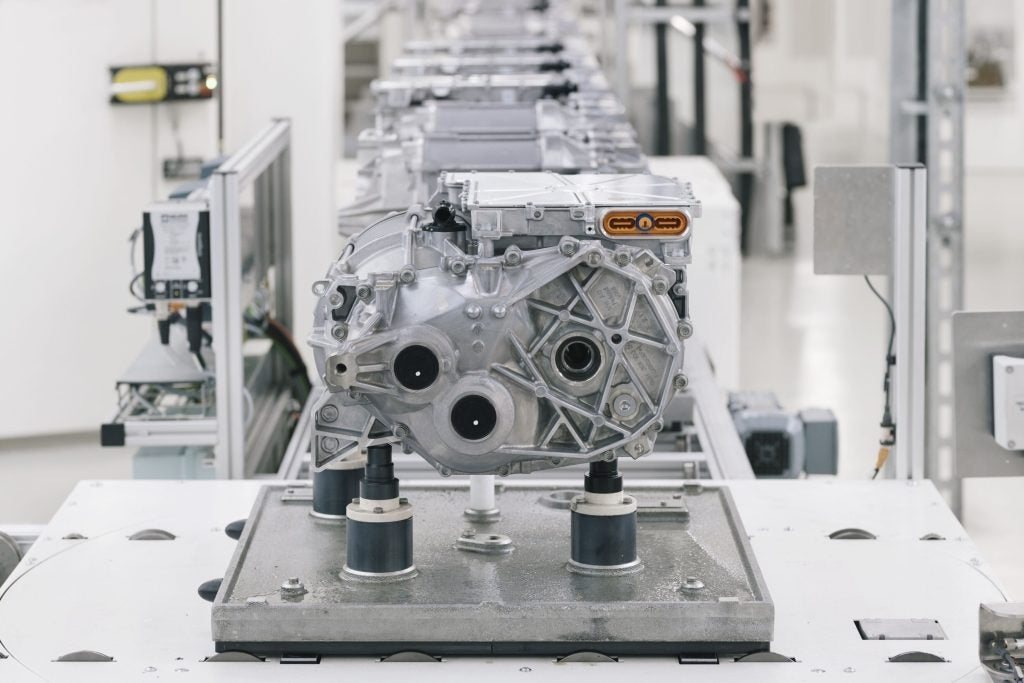

The most popular electric drive within the Group at present is the APP550, used in Volkswagen’s ID. family as well as in the Škoda Enyaq and CUPRA Tavascan.

To date, one million APP550 units have been manufactured at the VW Group Components plant in Kassel. Despite having the same dimensions as the predecessor model, it consumes around 20% less energy but increases torque and power by around 75% and 40% respectively – a marked improvement with respect to range, acceleration and noise levels.

In series production the APP550 delivers up to 240 kW and up to 560 Nm. The combined oil and water-cooling system optimises temperature control without requiring an additional pump.

The Volkswagen Group’s integrated network is responsible for the entire development of the electric drive systems – from engineering and industrialisation to power electronics and all the way up to logistics.

VW Group’s own pulse inverter to be used for electric drives in the Electric Urban Car Family

The pulse inverter that the Volkswagen Group is independently launching is a key component of electric drive systems. It is claimed the inverter being developed by Volkswagen Group Components will have advantages over externally sourced inverters by allowing for faster product development, cost reductions and more independent production – for future electric drive systems across multiple brands.

The company also says that using silicon carbide as a semiconductor material in the new APP290 electric motor will ‘deliver noticeable benefits for the models in the Electric Urban Car Family (including the ID. Polo, Škoda Epiq and CUPRA Raval) by increasing their range and improving performance in everyday driving’.

Currently, the APP290 electric motor developed and manufactured within the VW Group is expected to be available for several performance levels ranging from 85 kW (116 PS) to 166 kW (226 PS). It uses 400V technology.