ZF is ploughing EUR34m (US$40m) into its North East England camera plant in Peterlee as it ramps up new production lines and looks to add a further 80 jobs to the current 880-strong workforce.

The two-year project will address significantly growing demand for cameras which can support automated driving, while the extra engineers, production specialists and apprentices will work in an environment increasingly geared to Industry 4.0 techniques.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

“What we are doing today is already 4.0, it is just not badged as that,” ZF Peterlee plant director, Robin Finley told just-auto at the factory, around 30min south of Sunderland and the Nissan site. “Because there is so much business driven by Nissan in the North East, we got together as businesses and develop the North East Automotive Alliance.

“Nissan is part of that [as well as] al the big players in the area and some of our discussions are about 4.0. We have started the Manufacturing Innovation Group within that Automotive Alliance; it is looking at AGVs, data visualisation, but it is really encompassed by 4.0.

“I think where we are already today, we are at a far more advanced stage than many companies and we will be one of the market leaders when it comes to 4.0. If anything, I would expect ZF to be ahead of the curve, so I don’t think we have anything to worry about.”

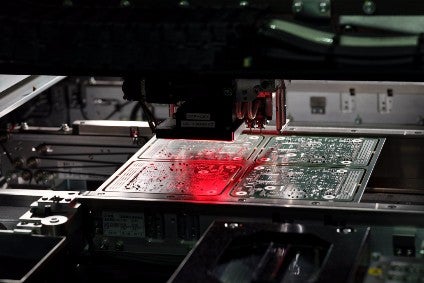

ZF Peterlee produces safety cameras with output currently running at 33,000 units per week, while in 2019 it will start manufacture of a new system incorporating Mobileye’s EyeQ4 technology, which has eight times greater object recognition capability than the current generation.

To be know as S-Cam 4, automakers will use the technology to support road safety and automated driving including Highway and Traffic Jam Assist. By 2020, production is expected to reach around 70,000 units per week.

ZF is already a significant employer in the region and news of additional jobs being triggered by S-Cam 4 development will be welcome for an area which is seeing some major companies shift from North East England to elsewhere.

“We have taken our headcount from 500 to 900 in the last four years,” added Finley. “The next three to four years will mean continuous growth. We were supported the Regional Growth Fund [and] the latest thing we have been tapping into is where I can get skills and training funding – a bit of national and regional.

“Everyone thinks the apprenticeship levy [UK government skills tax] means 16-18, it doesn’t, it means a 50 year old can go into a high level apprenticeship. We have paid [the levy] but we have made good use of that money – use it or lose it.”

ZF’s Peterlee factory currently offers apprenticeships in engineering as well as maintenance and is expanding the scheme to include other disciplines such as human resources, quality, and logistics.

The plant is on target to double the number of apprenticeships in place by the end of this year.

Peterlee is one of only three ZF locations globally producing the camera technology. ZF cameras support current driver assist systems including automatic emergency braking (AEB) and lane assist functions.

With around 420 individual components coming together to make each camera, each one takes around 23 seconds to assemble and test.