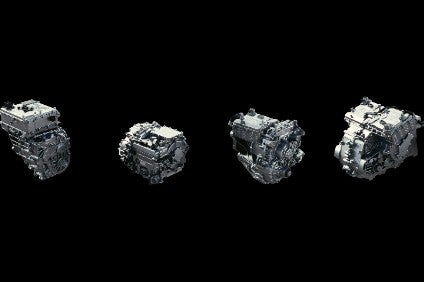

General Motors said its next-generation EVs will be powered by a family of five interchangeable drive units and three motors, known collectively as "Ultium Drive" as it works towards a fully electric model line, promising "significant advantages over GM's previous EVs in performance, scale, speed to market and manufacturing efficiencies".

Ultium Drive combines electric motors and single speed transmissions to apply power – from previously announced Ultium battery cells. GM will lead the design and development of the modular architecture which will be more responsive than internal combustion equivalents with precision torque control of motors. These, GM claimed, will offer industry-leading torque and power density across a wide range of vehicle types.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

"GM has built transmissions for many notable automakers," said Ken Morris, GM VP, autonomous and electric vehicle programs. "Making motors, transmissions, driveline components and systems are among GM's best known skills and our manufacturing expertise is proving not only transferable but advantageous as we make the transition to EVs."

Integrating power electronics into drive unit assemblies reduced mass by almost half from a previous EV generation, saving cost and packaging space while increasing capability by 25%.

This consolidation makes it easier to scale the drive packs across a planned future EV range.

"The power and versatility of these drive units will help GM migrate high output segments like pickup trucks and performance vehicles to all electric propulsion while providing the [range] to propel GM's EV portfolio well into the future," it said.

The drive line covers front-, rear- and all-wheel drive including high performance and off road capabilities.

All five drive units are expected to be powered by one or more of three motors including a primary front wheel drive motor, which can be configured for front- or rear-drive, and an all-wheel drive assist motor.

GM will save on vehicle design and production costs by the drive alongside its next generation of EVs.

"As with other propulsion systems that are complex, capital intensive and contain a great deal of intellectual property, we're always better off making them ourselves," said Adam Kwiatkowski, GM executive chief engineer, global electrical propulsion.

Most of the drive components, including castings, gears and assemblies, will be built with parts sourced worldwide at GM's existing global propulsion facilities on shared, flexible assembly lines, allowing the company to more quickly ramp up its EV production, achieve economies of scale and adjust its production mix to match market demand.

All GM electric vehicles built on the Ultium platform will be powered by Ultium Drive.