Ford said fuel efficiency improvements of up to 6% were achieved on the road after engineers tested different cylinder deactivation technologies on a working prototype.

To enable cylinder deactivation to take place at a wider range of engine loads and speeds, Ford engineers and Schaeffler Group developed a new dual mass flywheel which also minimised noise, vibration and harshness levels.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

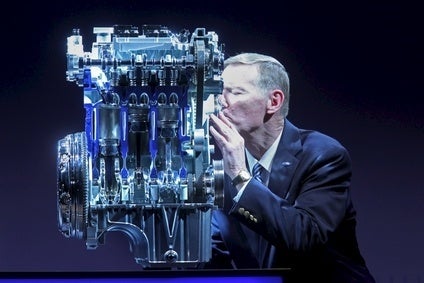

Cylinder deactivation is among a number of fuel efficiency improvement measures the automaker is investigating for its I3, one litre EcoBoost engine at the European Research and Innovation Centre in Aachen, Germany.

“Even for an aggressively downsized engine such as the 1.0-litre EcoBoost, a significant improvement in vehicle fuel economy could be found by exploiting cylinder deactivation,” the automaker said. “The highest priority in the development of new combustion engines for automotive applications is the ongoing reduction of fuel consumption.”

Downsized EcoBoost engines combine power with excellent fuel efficiency through direct fuel injection, turbocharging, and variable valve timing and were fitted ti one in four new Ford vehicles sold in Europe in 2014. The one-litre is the most popular and available, for most models with automatic as well as five- and six-speed manual transmissions, and across 10 model lines.

For testing, engineers equipped a Focus I3 with cylinder deactivation hardware to monitor deactivation of one cylinder, and also a rolling cylinder deactivation to run the engine in ‘half-engine’ mode.

The prototype was also fitted with a newly developed system that combined a dual mass flywheel, a pendulum absorber, and a tuned clutch disc which proved particularly effective at low revs. As well as enabling a wider operating range of cylinder deactivation, this system helped counteract any effect that the cylinder deactivation had on levels of noise, vibration and harshness.

Fuel efficiency improvements were recorded in homologated conditions and during test drives of the first prototype vehicle, for a typical commuter distance of 55km on a combination of motorway, city roads and rural roads, in and around Cologne, Germany.

Schaeffler urges more engine/transmission cooperation