Chinese electric vehicle (EV) battery manufacturer Contemporary Amperex Technology Company Limited (CATL) announced plans to spend up to CNY24bn (US$3.5bn) to build a new battery recycling and materials processing centre in China’s Guangdong province.

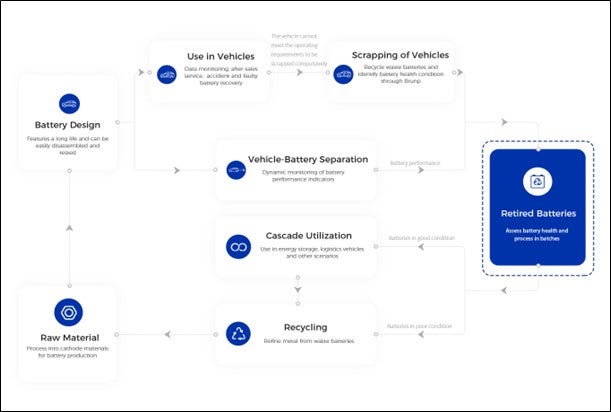

The Guangdong Bangpu Recycling Technology subsidiary said it planned to build the facilities in Foshan city with a capacity to recover 500,000 tons of minerals per year, including lithium and graphite, from end-of-life EV batteries. The company will recover and process the minerals for use in cathode and electrolyte materials mainly for new lithium iron phosphate EV batteries.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

Separately, the Contemporary Amperex Intelligence Technology (Shanghai) (CAIT-SH) subsidiary earlier this month signed an agreement to establish a production base for its CATL Integrated Intelligent Chassis (CIIC) in Yichun, in Jiangxi province.

The company said CAIT-SH was focused on design, production, sales and service of CIIC, a skateboard platform which integrates batteries, drivetrain and vehicle chassis systems, in a move aimed at strengthening its ties with local vehicle manufacturers.

The company said it would work with local EV startup Hozon Auto to develop a body on frame architecture for its EVs.