US-based automotive systems supplier BorgWarner has secured a programme award from a European original equipment manufacturer (OEM) to supply an 800V integrated drive module (iDM) for a range extended electric vehicle (REEV).

Mass production of the 800V iDM is scheduled to begin in 2029.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

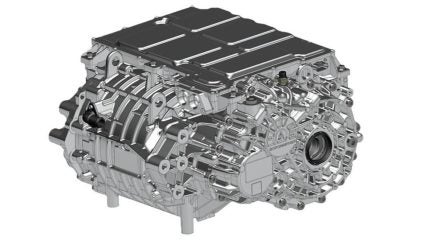

The “highly” integrated system incorporates a single electric machine design providing both generator and drive functionality.

It operates in conjunction with an inverter, two clutches and a dual-mass flywheel, and is paired at system level with the customer’s internal combustion engine (ICE).

In addition to generator functionality, the module supports an all-wheel-drive mode when required.

The inverter integrates BorgWarner’s “next-generation” Viper power switches and dual-side cooled power module technology.

The drive module features a fully integrated induction e-machine and gearbox for hybrid or electric vehicle applications.

The generator module includes a permanent magnet electric machine and a dual inverter mounted directly to the ICE, extending vehicle range while enabling electric vehicle performance alongside ICE operation when required.

BorgWarner stated that combining two major REEV functions into a single product supports vehicle architecture efficiency.

The platform has been developed to meet high-voltage and high-current operating requirements.

BorgWarner vice president and PowerDrive Systems president and general manager Stefan Demmerle said: “Securing this programme award underlines BorgWarner’s strength in electric drive technology and system integration. With the China team taking the lead and collaborating with a global team, we have created a highly integrated solution that balances performance, efficiency, and packaging.”

In a separate contract, BorgWarner has secured an agreement with a major North American OEM to supply an 800V secondary iDM and a generator module incorporating a dual inverter.

The systems will be integrated into a series of the automaker’s REEV trucks and large-frame SUV models, with production also set to begin in 2029.

Under the North American contract, the secondary iDM uses an induction electric machine designed to achieve high torque density while eliminating the need for permanent magnets.

The generator module features an optimised dual inverter design incorporating BorgWarner’s next-generation Viper power switch technology.

The North American award marks the introduction of BorgWarner’s next-generation Viper power module in production applications.

Production for this is also scheduled to begin in 2029.