Nissan Motor is the latest automaker to announce a comprehensive plant revamp in preparation for intelligent, electrified and connected cars.

As part of its Nissan Intelligent Mobility project, also intended to make production more flexible, efficient and sustainable, it will spend JPY33bn at its main Tochigi Plant in Japan, with work to end in 2020, and then expand new technology to its other factories worldwide.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

“We’re facing an unprecedented evolution in the capabilities of our vehicles,” said the automaker’s manufacturing and supply chain chief Hideyuki Sakamoto.

“This will also mean shifting the efforts of [workers] from techniques they’ve already mastered to new, unexplored areas.”

The planned next generation of electrified, intelligent and connected cars will add new complexity to design and construction, requiring major advancements in production engineering.

Pallet powertrain push

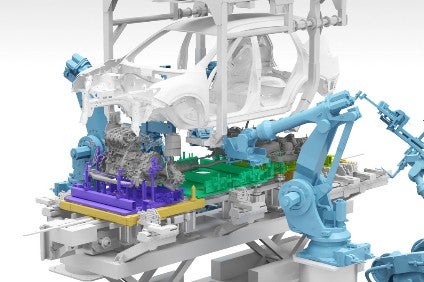

One such advancement is the universal powertrain mounting system developed at the automaker’s production engineering R&D centre.

Mounting powertrains in some cars is a lengthy process and strenuous work for assembly line staff, who must install multiple components in sequence.

Nissan’s new system uses an automated pallet to mount the entire powertrain at once. It measures the car’s dimensions during mounting, and the pallet makes micro adjustments accordingly. This ensures that powertrains are installed to within a small fraction of a millimetre.

The same pallet can mount three types of powertrains (internal combustion engine, hybrid and pure electric), and can assemble and mount 27 different powertrain module combinations.

Teaching robots craftsmanship

Specialist skills and processes which , until now, could only be performed by trained craftspeople have been, at least partly, digitised and robots trained to perform them around the clock. This, Nissan said, would allow its craftspeople to “focus on new, unexplored areas of expertise”.

Sealing is generally done by skilled workers as the necessary dexterity and speed can be acquired through training but isn’t easy to replicate. In addition to automating the process of applying sealant, engineers analysed the precise movements and gestures of trained workers when smoothing and finishing sealant, and calculated the pressure applied at each stage. Next, they converted this information to instructions for robots and made further refinements through extensive trial and error.

As a result, robots can now apply and finish sealant quickly and precisely along even the most complex of seams.

Robots make better workplaces

Robots can now perform certain strenuous tasks efficiently, freeing workers to perform more valuable jobs elsewhere on the line. This also improves ergonomics, making factories easier places to work.

One example is the installation of a headliner. Workers must enter each vehicle’s cabin to perform this physically demanding job. The task has become even harder as cars come with more connected features, adding to the number of devices in and around the headliners.

Nissan’s ide was to use robots to insert the headliner through the front of the vehicle and then fasten it. Sensors monitor changes in pressure and use a proprietary logic system to determine when the clips have snapped securely into place.

Lower environment impact

The automaker is also working to reduce the environmental impact of building cars and said its changes to paint process are particularly noticeable.

Car bodies must usually be painted at high temperatures, because the viscosity of paint is hard to control at lower temperatures. By contrast, bumpers are made of plastic, so they need to be painted at low temperatures. This requires two separate painting processes for one vehicle.

Nissan has developed a water-based paint that maintains the right viscosity at low temperatures, so bodies and bumpers can be painted together. This will cut carbon dioxide emissions from the process by 25%.

It will also use a water free painting booth that makes it possible to collect all waste paint and reuse it in other production processes.

“This new technology and innovations are at the heart of the company’s competitiveness,” said Sakamoto. “They will be rolled out globally in the coming years.”