The automotive industry is increasingly turning to more sustainable materials, both for interior and exterior applications.

Mercedes-Benz has recently announced the use of a leather alternative material which is made from recycled racing tyres, as well as plant-based proteins and biopolymers from INNOVERA material designed by Modern Meadow.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

Modern Meadow, a bio-design company, has been working with the OEM on its concept AMG GT XX EV, where one scrap tyre acts as a base for four square meters of the bio-designed material that looks, feels and smells like leather, but is animal-free.

This material has been designed as a breathable and waterproof fabric, and is lighter than traditional leather. INNOVERA is designed to be scalable meaning that manufacturers can integrate it into existing processes without investing in costly infrastructure.

We spoke to Modern Meadow CEO, David Williamson, PhD to learn more about the process that goes into creating INNOVERA, and to discuss the benefits that it offers.

Just Auto (JA): Can you provide some background on the company?

David Williamson (DW): Modern Meadow was established in 2011 in Brooklyn, New York, by founders Andras Forgacs, Francoise Marga, Gabor Forgacs, and Karoly Jakab with a clear mission: to create high-performance materials with sustainability at their core. Since then, the team has refined both the molecular design and production methods behind its innovations, resulting in materials that are not only rooted in renewable carbon but also seamlessly compatible with today’s manufacturing processes. The result of this work is INNOVERA, a next-generation material that delivers on both environmental responsibility and advanced performance.

INNOVERA is tailored for the needs of leather tanneries. Its formulation allows for seamless integration into the re-tanning phase of production without requiring any changes to existing infrastructure. This compatibility enables tanners to treat and finish INNOVERA just as they would with traditional animal hides, achieving everything from soft suedes to defined full-grain textures and patterns.

Beyond its ease of adoption, INNOVERA delivers notable material performance benefits. Compared to conventional leather, it is approximately twice as strong, 25% lighter, and demonstrates equal or superior performance in durability, and tear resistance. These attributes, combined with its scalable production, position INNOVERA as a compelling choice for use in sectors like automotive, where both technical specifications and aesthetic quality are essential.

Sustainability is a foundational element of INNOVERA’s design. The material supports circularity, with the potential for end-of-life reuse regardless of colour, feeding back into the production of new INNOVERA materials. It is composed of more than 80% renewable carbon content, including 60% ISCC PLUS-certified recycled nylon and 20% bio-based ingredients: soy protein and biobased polyurethane.

How did working with Mercedes-Benz come to be?

Mercedes-Benz selected us for an exclusive and intensive development partnership so together we can develop their INNOVERA-based LABFIBER Biotech Leather Alternative for series production and set new standards in vehicle interiors. The use of this material in the CONCEPT AMG GT XX is a first in automotive and something we want to roll out across the industry to other models.

Could you discuss the process of making the alternative leather (where are the materials sourced from, the time it takes, cost, CO2 savings, what materials etc.)?

INNOVERA is the future ready canvas upon which Mercedes-Benz’s LABFIBER Biotech Leather Alternative is built.

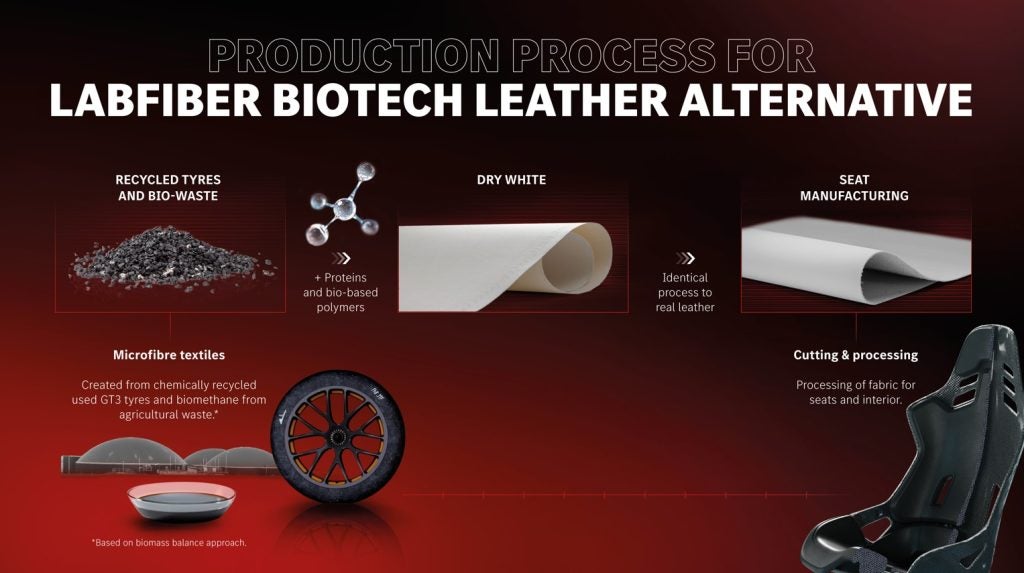

Our recipe for INNOVERA combines plant-based proteins, biopolymers and recycled rubber to create a hide-like canvas that brands and tanneries can use to create a final product, in much the same way that a quality painting canvas can be used by painters to create masterpieces.

INNOVERA is supplied to brands and tanneries as dry white, a semi-finished material that bypasses the most resource-intensive steps that are common in the tanning process. This is good because it allows for the production of a leather-like product with considerably less water consumption. In contrast to artificial leather, INNOVERA’s innovative combination of biopolymers, plant-based proteins and recycled rubber replicates the molecular structure of genuine leather, meaning it can be processed like genuine leather hides in retanning workflows. As a result, it has the same high quality look and feel as materials like nubuck leather as well as natural aging properties. INNOVERA is a great material for tanneries, in part, because it requires no cold storage, desalting or stabilization and integrates directly into traditional post-tanning and finishing workflows. And, the material is built for a circular lifecycle: the content derived from recycled plastic can be fully recycled.

Designers and tanners can then take this canvas and create a finished product that’s tailored to their needs.

Designers and tanners can then take this canvas and create a finished product that’s tailored to their needs. This is what Mercedes-Benz has done, using INNOVERA to produce LABFIBER Biotech Leather Alternative.

In our partnership with Mercedes-Benz, we produced INNOVERA with the same recipe, only this time the recycled rubber component was made up of chemically recycled AMG GT3 racing car tires that were used in tough competition. This canvas is then finished according to Mercedes-Benz standards to produce LABFIBER Biotech Leather Alternative. The black seat pads of the CONCEPT AMG GT XX’s bucket seats are covered with the material’s Nappa-look variant, giving it both a luxurious feel while also fortifying the car with a high-quality material. The bio-design inherent to INNOVERA means that the LABFIBER Biotech Leather Alternative is breathable and waterproof as well as lighter than real leather. INNOVERA’s high tensile strength (up to two-fold greater than genuine leather) provides LABFIBER Biotech Leather Alternative with a necessary durability. And because of its low thermal conductivity, the material does not heat up quickly, even in summer—all of which are valuable features for automobile interiors.

INNOVERA’s recycled rubber comes from a chemical recycling process. In it, pyrolysis oil is first produced using old tyres and certified biomethane from agricultural waste. These are then processed into plastic fibers in accordance with the mass balance method. These microfibers, in turn, are used to create a semi-finished product to which vegetable proteins and bio-based polymers are added.

For INNOVERA’s application in the CONCEPT AMG GT XX, Mercedes-AMG uses pyrolysis oil produced from racing tyres that were actually used in competition on AMG GT3 customer racing cars. One scrap tire provides the basis for approximately 43 square feet of new LABFIBER Biotech Leather Alternative. The innovative material is configured for closing material loops. It embraces complete chemical recycling, whereby the end-product, LABFIBER Biotech Leather Alternative, is of a higher value than the stock material, scrap tires, making a perfect case of upcycling.

What are the benefits of this process over traditional leather?

INNOVERA offers several advantages. First, it provides tanners with a new material that preserves the artisanal quality of leathercraft while opening the door to innovation. Unlike traditional leather, which relies solely on animal hides, INNOVERA introduces a scalable alternative that expands creative and commercial possibilities, enabling the production of high-quality, animal-free products that appeal to a growing base of conscious consumers.

The material also helps address two major challenges the leather industry faces: resource limitations and competition from low-cost plastics. With only a finite number of high-quality suitable animal hides available globally, increasing production has natural limits. INNOVERA bypasses that constraint by offering a consistent, alternative raw material that can supplement traditional hides, allowing for growth without relying solely on animal sources.

Economically, INNOVERA positions tanners to better compete with synthetic materials. While much of the market is flooded with inexpensive plastic-based alternatives, INNOVERA allows leather producers to reclaim some of that space, delivering performance, sustainability, and craftsmanship that other synthetics simply can’t match.

INNOVERA is engineered to meet rising regulatory and consumer demands for sustainability, with a significantly lower carbon footprint than both traditional leather and most synthetics.

And importantly, it supports environmental progress. INNOVERA is engineered to meet rising regulatory and consumer demands for sustainability, with a significantly lower carbon footprint than both traditional leather and most synthetics. It’s a forward-looking solution for a heritage industry that wants to grow without compromise.

Could you discuss the scalability of this process?

Scalability was a core focus in the development of INNOVERA. From the outset, the material was designed using widely available, highly sustainable raw inputs, ensuring consistent global supply without dependence on niche or hard-to-source components.

The production process itself was also intentionally built to align with existing industrial infrastructure. Whether in North America, Europe, or Asia, the equipment needed to convert INNOVERA’s raw materials into its semi-finished form, the dry white, is already in place. This eliminates the need for specialized machinery, making it easier to produce the material at scale across multiple regions.

Downstream, INNOVERA integrates directly into current tannery workflows and existing supply chains. Brands can scale production quickly and efficiently, working with the manufacturing and finishing partners they already rely on, without costly overhauls or added complexity. This makes INNOVERA not only scalable in theory, but truly ready for widespread adoption today.