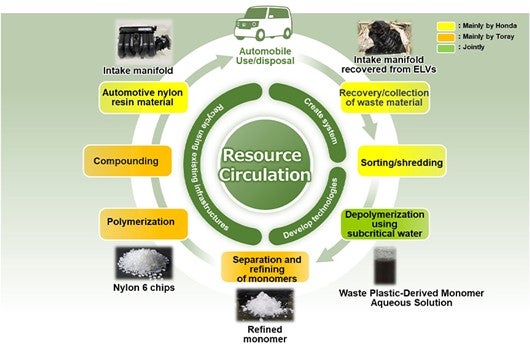

Honda R&D and Toray Industries have begun trialling closed loop recycling of nylon resin recovered from end of life vehicles (ELVs).

The material’s strength, heat resistance and chemical resistance makes it suitable for automotive parts exposed to heat, petrol, and oils.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

Honda and Toray would install and verify a pilot facility with a processing capacity of 500 tonnes of resin per year.

The companies said they aimed to commercialise the process by 2027.

The treatment of automotive nylon resin waste has to date been limited to recovery and use of heat generated during incineration. This is due to the technical difficulty of sorting, collecting, and recycling.

The two companies claimed to have succeeded in ‘monomerising’ recovered nylon resin back to its molecular state using subcritical water.

Using subcritical water as a solvent recycles the nylon resin in less time with a higher yield and less environmental impact compared to conventional acid catalysts.

The trial, approved by Japan’s environment ministry, would verify the recycling of intake manifolds recovered from ELVs in Japan and generate recycled material with the same performance and quality as new.