Safety equipment specialist supplier Autoliv has unveiled new airbag technology, based on the Bernoulli Principle which states that, as the speed of a fluid increases, the static pressure decreases.

Traditionally, airbags rely on internal gas pressure to inflate rapidly during a crash. However, Autoliv’s design uses pressure differences to draw in surrounding air, augmenting the inflation process.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

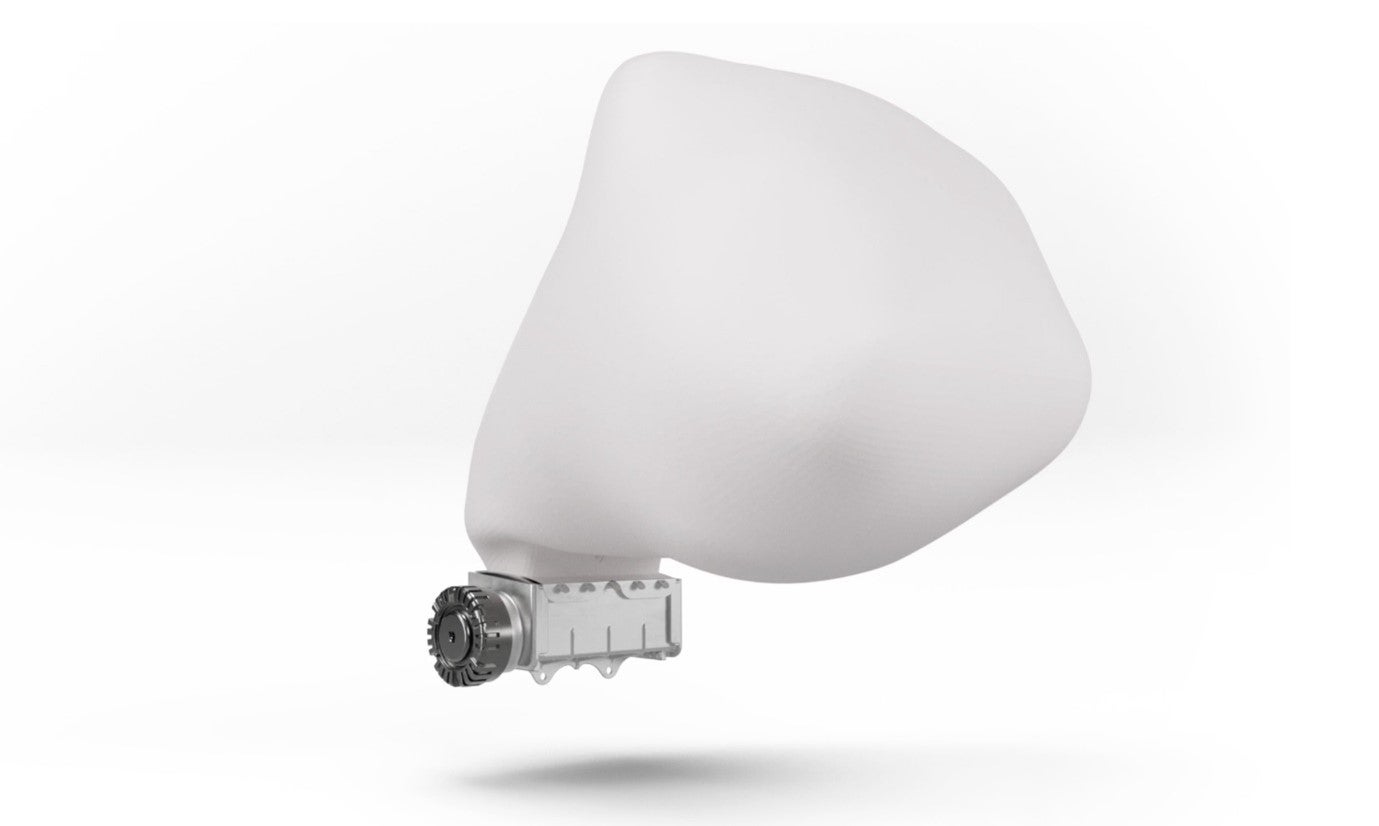

The new technology incorporates an inflator which receives a signal indicating a collision. This then propels high pressure gases at high speeds through multiple inlet tubes.

As the gases flow through the tubes, they create a vacuum effect, drawing in the ambient air and generating aspiration.

The combination of pressure dynamics and aspiration allows for the inflation of a larger airbag with a smaller inflator.

Autoliv claims this offers increased efficiency while significantly reducing development time and costs.

“The Bernoulli airbag generates less heat, is lighter, and can reduce customer development testing in the US by 30%. Low risk deployment requirements can be met with a single stage inflator,” said chief technical officer Jordi Lombarte in a statement.

The new airbag will be available to OEMs in the third quarter of this year.