Volkswagen Groups’s supervisory board has approved new ‘strategic’ plant assignment plans which, it said, “reflects the challenges of the next five years and lays the necessary foundations”.

As well as refocusing the Zwickau plant as an e-mobility production centre, the plants in Emden and Hanover will be converted to build electric vehicles with new ID family models due off assembly lines from 2022.

A new plant is planned, too.

“In order to serve growth in Europe going forward, the group will be expanding its production capacity post-2022 with an additional plant in eastern Europe,” VW said.

Group production chief Oliver Blume said in a statement: “We have redefined the strategic guideposts for future plant assignment. We are making our plants fit for the future. Among other things, this includes bundling cross-brand product families to maximise synergies and cost benefits. That is how we will be realising the full potential of the group.”

All-electric cars will be built in Emden and Hanover from 2022, these will be small cars and sedans across several brands from Emden while Hanover will specialise in the ID Buzz family but continue building vehicles with conventional drives.

How well do you really know your competitors?

Access the most comprehensive Company Profiles on the market, powered by GlobalData. Save hours of research. Gain competitive edge.

Thank you!

Your download email will arrive shortly

Not ready to buy yet? Download a free sample

We are confident about the unique quality of our Company Profiles. However, we want you to make the most beneficial decision for your business, so we offer a free sample that you can download by submitting the below form

By GlobalData“German plants are particularly well suited to making the transformation to the production of electric vehicles, given the high manufacturing expertise and qualification level of our employees. We are aligning the three plants in Zwickau, Emden and Hanover to our electrification strategy and thereby laying the groundwork for expanding our electric fleet and thus meeting the CO2 targets,” Blume added.

Skoda to build Passat

Production of the Volkswagen Passat range will be moved to the Skoda plant in Kvasiny, Czech Republic, and those models will be built there together with Skoda’s own Superb and Kodiaq from 2023. The Skoda Karoq and Seat’s Ateca, currently produced in Kvasiny, will be transferred to a new group multi-brand plant in eastern Europe – location has yet to be determined.

Group and general works council chairman, Bernd Osterloh, said: “I am particularly proud that we have succeeded in locating a large share of e-mobility production at our plants here in Germany, because the markets in Germany and western Europe, along with China and the US, will lead the way in introducing electric vehicles.

“The transition to e-mobility is no longer wishful thinking, it starts right here. And fewer jobs as a result of this transition is also part of the overall picture. That is something we have stated on several occasions.

“I am aware that is why many colleagues, particularly in Emden and Hanover, are worried about the transformation. As employee representatives we have taken action: a 10-year employment guarantee excludes compulsory redundancies until the end of 2028. We can make adjustments via the demographic curve so that no one loses their job.”

He added the transformation posed “enormous challenges for our workforce and the whole automotive sector”.

But he noted: “Here at Volkswagen, we are shaping this change from a position of strength and thus sending a clear message to the entire industry. We are bringing the future to Germany: emotional electric vehicles, innovative mobility concepts and the megatrend of autonomous driving are being built and made real right here in our backyard. That offers great opportunities for Volkswagen and the workforce.

“The supervisory board has once again approved enormous investments, many of which again relate to equipment, products and research at the German sites. From the viewpoint of our more than 660,000 employees all over the world – 290,000 of them in Germany – that is a great success. Because our long-term market survival hinges on stunning vehicles, services and research activities. This clearly calls for first-class conditions for our workforce. And we have laid the groundwork for that.”

According to VW, the most important criteria for plant assignment are optimal utilisation of existing capacity, platform orientation and volume bundling.

“As a result, flexible multi-brand plants will become increasingly common in order to harness the advantages of the flexible production network. Efforts will be systematically geared to reusing existing resources and factory structures and to cross-brand standardisation with a view to increasing productivity and reducing factory costs and investments.

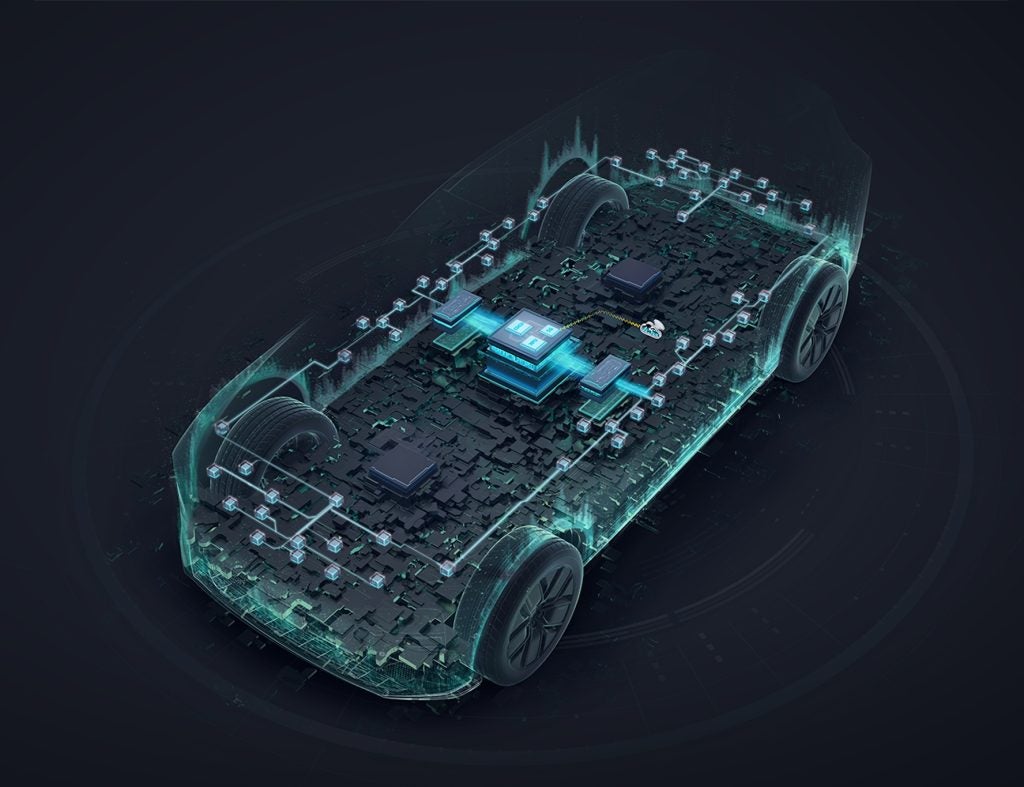

“The group is addressing the digital transformation of its plants to leverage further efficiencies.”

The group production unit has targeted a 30% increase in productivity by 2025. Backed by good progress in recent years, the environmental impact of the plants should be almost halved within the same timeframe.

“We have set ourselves clear and ambitious goals,” Blume said.

“Production must be a strategic competitive advantage for the group.”