Asahi Kasei has agreed a deal with Shell Eastern Petroleum to supply butadiene derived from plastic waste and biomass.

The chemicals company plans to begin producing and marketing sustainable solution polymerised styrene butadiene rubber (S-SBR) using sustainable butadiene at its plant in Singapore by the end of March 2022.

S-SBR is a type of synthetic rubber used mainly for eco friendly tyres for which demand is growing due to stricter environment regulations.

“S-SBR is recognised as an optimum material for eco friendly tyres,” Asahi Kasei claimed.

“Against this background, there is rising demand for greater sustainability of S-SBR as a material.”

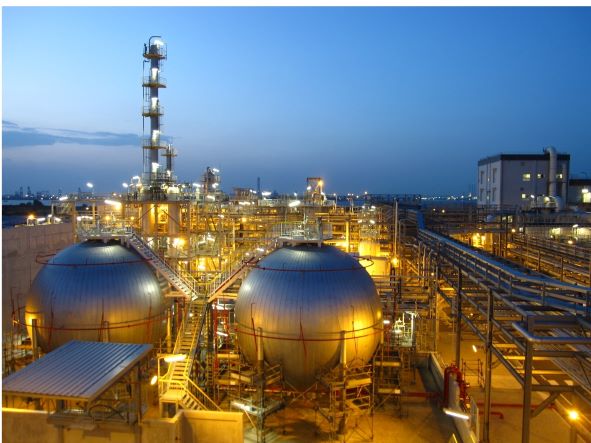

Shell will produce butadiene by the mass balance method in two ways at Bukom.

How well do you really know your competitors?

Access the most comprehensive Company Profiles on the market, powered by GlobalData. Save hours of research. Gain competitive edge.

Thank you!

Your download email will arrive shortly

Not ready to buy yet? Download a free sample

We are confident about the unique quality of our Company Profiles. However, we want you to make the most beneficial decision for your business, so we offer a free sample that you can download by submitting the below form

By GlobalDataAsahi Kasei claimed to be the world’s first company to use butadiene derived from plastic waste, and the first Japanese company to use butadiene derived from biomass, for S-SBR production.